VOLVO EW140 Classic inheritance, brand new upgrade

VOLVO EW140 Classic inheritance, brand new upgrade

Small wheel excavator

EW140 CN4

Configuration parameters

Standard: ● Option: ○ Reference value: * To be refined: /

1. Performance parameters:

|

force |

Traction force |

77.5 |

kN·m |

|

Bucket Digging Force - ISO |

103.3 |

kN |

|

|

Bucket Rod Digging Force - ISO |

79.9 |

kN |

|

|

Rotation torque |

41.9 |

kN·m |

|

|

speed |

Reverse speed |

11.5 |

r/min |

|

Walking speed (road / field / crawl) |

37/9/3.6 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

/ |

° |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Volvo D4J |

|

|

rated power |

110/2000 |

kW/rpm |

|

Maximum torque |

609/1600 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

DOC+DPF+SCR |

3. Hydraulic system:

|

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

|

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*164 |

L |

|

The overflow valve settings: |

||

|

Execute a hydraulic circuit |

32.4/36.3 |

MPa |

|

Turning the oil road |

26.5 |

MPa |

|

Walking the oil road |

36.3 |

MPa |

|

Leading oil road |

3.9 |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

4400 |

mm |

|

Fighting clubs |

2100 |

mm |

|

The shovel fighter looks |

0.6 |

m³ |

5. The chassis system:

|

Weight of weight |

2050 |

kg |

|

Number of tyres |

4-4 |

|

|

Tire Specifications |

9.00-20 18PR |

|

|

tread |

1944 |

mm |

|

wheelbase |

2800 |

mm |

6. Amount of oil and water added:

|

Fuel tank |

250 |

L |

|

Urin boxes |

25 |

L |

|

Hydraulic system |

200 |

L |

|

Hydraulic fuel tank |

80 |

L |

|

Engine oil |

16 |

L |

|

Antifreeze Solution |

26 |

L |

|

Reverse gear oil |

3.9 |

L |

|

gearbox |

2.5 |

L |

|

Differential of car and bridge : |

||

|

Maebashi |

10.5 |

L |

|

The back bridge |

12.5 |

L |

|

End drive mechanism |

4x2.5 |

L |

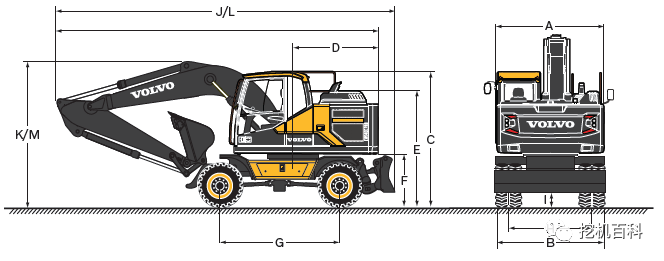

7. Form factor:

|

A |

Total upper structure width |

2490 |

mm |

|

B |

Total width |

2500 |

mm |

|

C |

Total height of the driver's room |

3096 |

mm |

|

D |

Tail pivot radius |

2290 |

mm |

|

E |

Total height of engine cover |

2695 |

mm |

|

F |

Weight-to-earth gap * |

1208 |

mm |

|

G |

wheelbase |

2800 |

mm |

|

H |

tread |

1944 |

mm |

|

I |

Minimum distance from the ground * |

350 |

mm |

|

J |

Total length (walking status) |

7555 |

mm |

|

K |

Total arm height (walking status) |

3455 |

mm |

|

L |

Total length (state of transport) |

7595 |

mm |

|

M |

Total arm height (transport status) |

3175 |

mm |

|

*: No track plate teeth |

|||

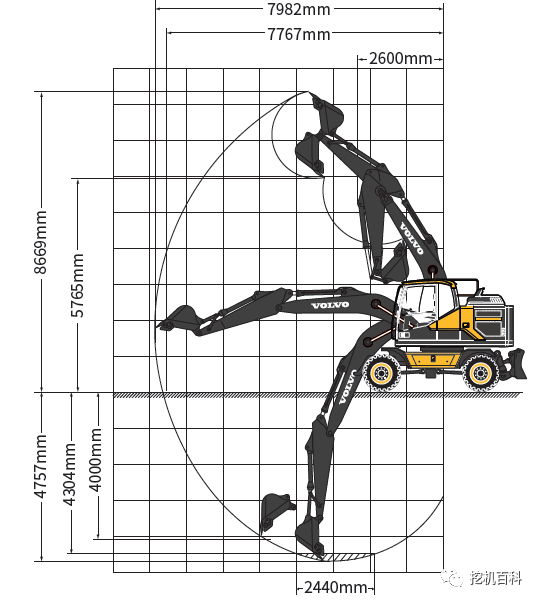

8. Operational scope:

1. Mature engine technology

-

The EW140 is equipped with a Volvo D4 engine that meets the "National Four" emission standard. Since its birth in 2014, the engine has gone through the rigors of the global market.

-

Thanks to nearly 10 years of technical testing, verification and improvement, this engine delivers exceptional quality, reliability and efficiency levels that customers can rely on.

2. Higher performance

-

The enhancement capacity increased by approximately 22 percent, the excavation power increased by about 5.7 percent, and the machine performance reached a new level.

-

Through an integrated machine control system, the most accurate engine speed can be selected within nine speed ranges, thus selecting the settings most suitable for the job task.

-

The new ECO mode further improves fuel efficiency without any loss in performance.

3. Power increases, fuel consumption decreases

-

Complete larger task tasks better, stronger, and faster.

-

Equipped with the powerful D4 Volvo engine, the EW140 delivers high torque at low revs and consistently high productivity.

-

When the steering wheel and pedals are not started, the automatic idling system reduces the engine speed to idle to reduce fuel consumption and cabin noise levels.

-

The optional engine automatic shutdown feature helps you shut down the machine after a preset period of inactive activity, saving you time and money.

4. Get all the tools at once

-

All tools are placed in a large toolbox, which is very conveniently installed in the middle of the side steps of the machine.

-

To make it easier to operate, the grease tank can be placed on the other side of the machine to help you get back to work quickly.

1. Excellent view.

-

With rear-view and side-view cameras, you can ensure mobility and flexibility when walking - especially when driving on the highway. The camera is mounted on the machine to make it easy to see the conditions around the machine from different angles.

-

Both views are shown on the color monitor, making the working environment more comfortable. Cruise control helps you focus on the road ahead, further enhancing transportation convenience.

2. Easy operation, excellent control performance

-

Using an ergonomically designed control handle, the machine can be controlled with one click.

-

The right lever controls forward and backward, and the left lever controls the bridge lock. A single action or a composite operation will respond quickly and run smoothly, with excellent operational performance.

-

The electro-hydraulic system and the main control valve improve control performance and fuel efficiency, ensure that each operation can provide the appropriate flow.

3. Work easily

-

For ease of operation and reduction of operator fatigue, the Comfort Drive Control feature enables the operator to drive the machine at speeds up to 20 km / h (12 mph) without having to take his hands off the joystick.

-

Volvo's pioneered automatic excavator brakes allow you to start work straight after stopping. When the machine's speed is reduced to zero, the brake and swing lock automatically join together.

3. Assisted mining systems

-

The Volvo Assisted Mining System is supported by a 10-inch Volvo Assistive Driving System display, Equipped with a set of intelligent applications that optimize the mining process, including 2D, 3D, In Field Design, and On-Board Weighing, machine productivity can be maximized.

1. Taking on a difficult task

-

Volvo's durable design and perfectly matched Volvo transmissions provide excellent control that ensures smooth walking and superior performance, resulting in high productivity.

-

The strong structure easily absorbs the shocks transmitted by excavators, and the durability is further improved by reinforced welding between the central rack and side frames and the arms and arms cylinder supports.

2. Lifting, loading and consolidating operations

-

The reinforced arms and arms extend further, dig deeper, lift higher, operate at a maximum distance of 7.9 meters and have long-lasting performance.

-

The rigid earth shovels and legs improved machine stability and increased versatility, enabling the excavator to perform a variety of operational tasks.

3. Extending the uptime

-

Anti-sliding boards, wide steps and enough handrails, as well as properly positioned guardrails, make the repairs quick and easy.

-

Grouped filters and central lubrication points are easily accessible from the ground, making repair and maintenance operations more convenient.

-

The new splash-proof protective device for urea tanks makes urea filling faster and more convenient, while also reducing the risk of spillage and subsequent corrosion.

4. Easily monitor the state of your machine

-

The new generation of vehicle communication hardware PSR brings a new upgraded car networking service experience. WOW + Smart Cloud platform enables you to optimize your fleet and maximize productivity through real-time tracking, machine state in service, geographic / temporal fence management, and equipment utilization reporting.

-

The system provides machine-related reports that show how each machine is being used and how efficiently the hands are working, and can help you determine training needs.

-

Through WO + wisdom cloud platform or Volvo construction equipment APP to view the equipment real-time condition, WO peace of mind report, maintenance / alarm reminder, etc. The Volvo Maintenance Hours Centre provides 24 / 7 machine monitoring, provides monthly reports, and notifies you when preventive maintenance measures need to be taken.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE