VOLVO EC400 Classic inheritance, brand new upgrade

VOLVO EC400 Classic inheritance, brand new upgrade

Large excavator

EC400

Summary

Configuration parameters

Standard: ● Option: ○ Reference value: * To be refined: /

1. Performance parameters:

|

force |

Traction force |

277 |

kN·m |

|

Bucket Digging Force - ISO |

242.7 |

kN |

|

|

Bucket Rod Digging Force - ISO |

219.1 |

kN |

|

|

Rotation torque |

131 |

kN·m |

|

|

speed |

Reverse speed |

10.2 |

r/min |

|

行走高速/低速 |

5.1/3.3 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

° |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Volvo D13J |

|

|

rated power |

230/ |

kW/rpm |

|

Maximum torque |

1692/1275 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

DOC+DPF+SCR |

3. Hydraulic system:

|

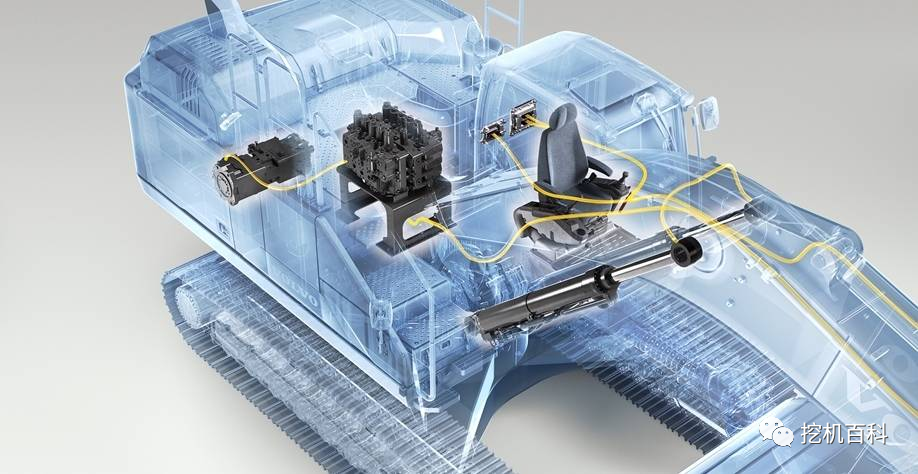

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

Double turnaround |

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*300 |

L |

|

The overflow valve settings: |

||

|

The working oil road |

32.4 |

MPa |

|

Turning the oil road |

27.9 |

MPa |

|

Walking the oil road |

35.3 |

MPa |

|

Leading oil road |

/ |

MPa |

|

Power exertion |

35.3 |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

6450 |

mm |

|

Fighting clubs |

2600 |

mm |

|

The shovel fighter looks |

2.0~2.2 |

m³ |

5. The chassis system:

|

Weight of weight |

/ |

kg |

|

Number of trackpads - one side |

/ |

section |

|

Number of cogs - one side |

2 |

individual |

|

Number of support wheels - one side |

9 |

individual |

|

Running board width |

600 |

mm |

|

Chainrail steering agency - single side |

2 |

individual |

6. Amount of oil and water added:

|

Fuel tank |

472 |

L |

|

Urin boxes |

62.5 |

L |

|

Hydraulic system |

500 |

L |

|

Hydraulic fuel tank |

225 |

L |

|

Engine oil |

42 |

L |

|

Antifreeze Solution |

60 |

L |

|

Walking brake gear oil |

2*6.8 |

L |

|

Reverse gear oil |

6.5 |

L |

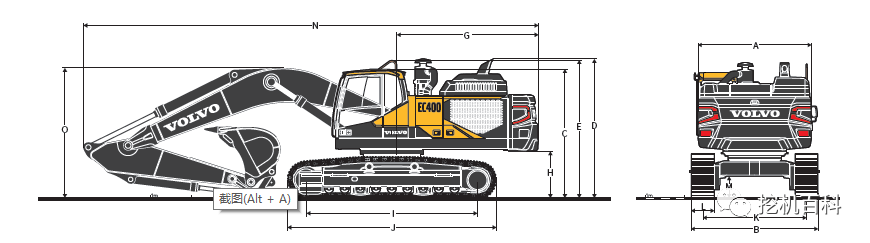

7. Form factor:

|

A |

Total upper structure width |

2990 |

mm |

|

B |

Total width |

3340 |

mm |

|

C |

Total height of the driver's room |

3220 |

mm |

|

D |

Total height of the drainage shield |

3465 |

mm |

|

E |

Total height of railings |

3440 |

mm |

|

Total height of railings (expanded) |

3685 |

mm |

|

|

Total height of railings (folding) |

3215 |

mm |

|

|

G |

Tail pivot radius |

3600 |

mm |

|

H |

Weight-to-earth gap * |

1150 |

mm |

|

I |

Wheel spacing |

4240 |

mm |

|

J |

Track length |

5180 |

mm |

|

K |

Track length |

2740 |

mm |

|

L |

Trackboard width |

600 |

mm |

|

M |

Minimum distance from the ground * |

500 |

mm |

|

N |

Total length |

11310 |

mm |

|

O |

Total arm height |

3580 |

mm |

|

*: Does not include track plate flanges height |

|||

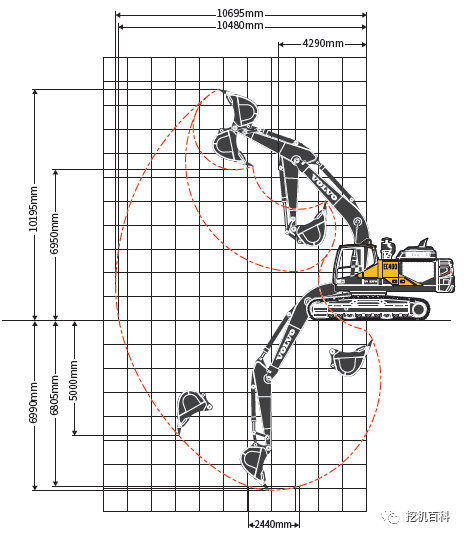

8. Operational scope:

Quality comes from design

The EC400 is equipped with the technically lean Volvo D13 engine for superior quality. The durable design, easy repair and maintenance, and all-in-one safety features contribute to this high quality machine.

1. Time-tested engine technology.

-

Since 2014, the Volvo D13 engine, which is in line with the national fourth standard, has been tempered by the global market. With a decade of carefully honed technological advantages, its overall strength continues to strengthen, providing solid and reliable product quality and satisfactory operational efficiency to users around the world.

2. Safety of both interior and exterior repair

-

Anti-skid plates and handrails ensure easy and safe access to the ROPS standard driving room.

-

After entering the driver's room, the operator can obtain an excellent field of view through the rearview camera. If the operator does not properly tie the seat belt, the seat belt sound alarm function will issue a voice alarm.

3. Engine Protection

-

Standard configurations of engine delayed downtime enable your turbocharger to work in excellent condition for longer periods of time.

-

To avoid overheating, when the turbocharger cools to a suitable temperature, the smart setting turns off the machine in time, or it can be set by the operator to turn it on automatically.

4. Repairs are quick

-

The centralized arrangement of filters and lubrication points makes repairs and maintenance more convenient and faster, which can maximize uptime.

-

Simply open the side door to service the single-layered chiller from the ground. Heat coolers, pressurized air coolers and hydraulic oil coolers are installed side by side in the same layer to maximize efficiency, reduce blockage and simplify cleaning operations.

Productivity soared

The EC400 features a large bucket design with a larger load per bucket, increasing productivity by approximately 16%.

1. The industry famous driver's room

-

Volvo's caring cabs, known for their low noise, low vibration and good visibility, make it comfortable and efficient for operators to operate in such an environment.

-

The overall layout for easy operation, heating seats and ergonomic control devices further improve the operating environment of the driver's room, helping to improve the efficiency of operators.

2. Time-tested motivations

-

Thanks to generations of proven Volvo engine technology, the EC400 delivers very high torque at low revs, excellent performance and reliability.

3. Assisted mining systems

-

The Volvo Assisted Mining System is supported by a 10-inch Volvo Assistive Driving System display, Equipped with a set of intelligent applications that optimize the mining process, including 2D, 3D, In Field Design, and On-Board Weighing, machine productivity can be maximized.

4. Clean air guns

-

Clean air guns are particularly useful when operating in dusty environments. The nozzle of the air gun can be used to clean the driving interior and other areas, making the operator more comfortable and maintaining more conveniently.

Higher fuel efficiency

1. Play its full part

-

Smart engine features, such as automatic engine idling and automatic engine downtime, eliminate unnecessary fuel consumption and various types of wear, while lowering operating costs and reducing environmental impact, so that every drop of oil makes a difference.

2. Various modes of work

-

Using unique Volvo technology, a variety of operation modes are provided through accelerator control to achieve superior performance. When the operator selects a mode of operation: I (idle), F (fine), G (normal), H (heavy) and P (maximum power), the system has set the corresponding speed to achieve greater efficiency.

3. Core components have long-lasting performance

-

Hydraulically driven, inverted cooling fans (electronically controlled) regulate the temperature of the core components to ensure longer-lasting performance.

-

The fan only starts automatically when needed, minimizing noise and fuel consumption.

-

The inversion function allows the fan to blow in the opposite direction, allowing the fan to clean itself.

4. Stay up to date on what's happening

-

The machine features, combined with Volvo services, help you monitor your fuel usage and further reduce your running costs.

-

The fuel meter displays real-time fuel consumption and average fuel usage information to keep you up to date.

-

The Volvo + Fuel Consumption Report provides a clear explaination of the fuel consumption of a single machine and helps identify areas where fuel efficiency can be improved.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE