HITACHI ZX520LCH-6A Classic inheritance, brand new upgrade

HITACHI ZX520LCH-6A Classic inheritance, brand new upgrade

Large excavator

ZX520LCH-6A

Configuration parameters

Standard: ● Option: ○ Reference value: * To be refined: /

1. Performance parameters:

|

force |

Traction force |

329 |

kN·m |

|

Bucket Digging Force - ISO |

296/295 |

kN |

|

|

Bucket Rod Digging Force - ISO |

224/263 |

kN |

|

|

Rotation torque |

148 |

kN·m |

|

|

speed |

Reverse speed |

9.3 |

r/min |

|

行走高速/低速 |

5.5/3.7 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

70% |

|

|

Ground is higher than pressure |

82 |

kPa |

2. Powertrain:

|

Engine Model |

Isuzu 6WG1 |

|

|

rated power |

296/1800 |

kW/rpm |

|

Maximum torque |

2050/1300 |

Nm/rpm |

|

discharge volume |

15.681 |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

EGR |

3. Hydraulic system:

|

The technical route |

Electrically controlled positive flow |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

Double turnaround |

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*385+34 |

L |

|

The overflow valve settings: |

||

|

The working oil road |

31.9 |

MPa |

|

Turning the oil road |

28.4 |

MPa |

|

Walking the oil road |

35.3 |

MPa |

|

Leading oil road |

3.9 |

MPa |

|

Power exertion |

35.3 |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

2-170-115 |

mm |

|

Bulk fuel tank |

1-190-130 |

mm |

|

The shovel oil tank |

1-170-120 |

mm |

4. Working appliance:

|

ZX520LCH-6A |

ZX520LCH-6A(BE) |

||

|

Move your arms |

7000 |

6300 |

mm |

|

Fighting clubs |

3400 |

2900 |

mm |

|

The shovel fighter looks |

2.1/2.5/3.0 |

2.5/3.0 |

m³ |

|

Corresponding material density |

1800/1500/1100 |

1800/1500 |

kg/ m³ |

5. The chassis system:

|

Weight of weight |

9080 |

kg |

|

Number of double-barred trackpads - one side |

53 |

section |

|

Number of cogs - one side |

2 |

individual |

|

Number of support wheels - one side |

9 |

individual |

|

Running board width |

600 |

mm |

|

Chainrail steering agency - single side |

3 |

individual |

6. Amount of oil and water added:

|

Fuel tank |

675 |

L |

|

Hydraulic system |

517 |

L |

|

Hydraulic fuel tank |

290 |

L |

|

Engine oil |

52.5 |

L |

|

Antifreeze Solution |

70 |

L |

|

Walking brake gear oil |

2*11 |

L |

|

Reverse gear oil |

2*6.7 |

L |

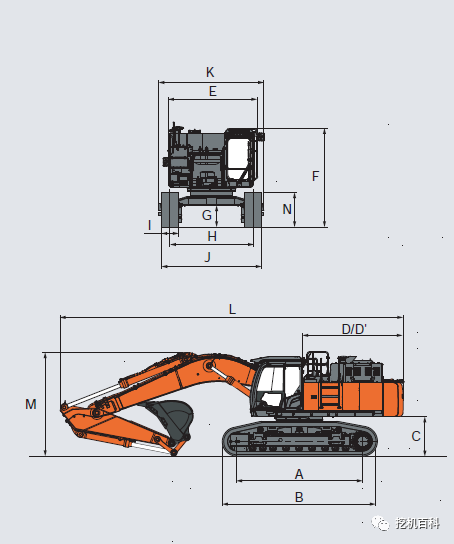

7. Form factor:

|

ZX520LCH-6A |

ZX520LCH-6A(BE) |

|||

|

A |

Wheel spacing |

4470 |

4470 |

mm |

|

B |

Lower walking body length |

5470 |

5470 |

mm |

|

C |

Gap between weight and ground |

1270 |

1360 |

mm |

|

D |

Backend pivot radius |

3680 |

3680 |

mm |

|

D' |

Backend length |

3660 |

3660 |

mm |

|

E |

Total width of the upper pivot platform |

3055 |

3055 |

mm |

|

F |

Total height of the driver's room |

3360 |

3360 |

mm |

|

G |

Minimum distance from the ground |

560 |

560 |

mm |

|

H |

gauge |

2740 |

2740 |

mm |

|

I |

Trackboard width |

600 |

600 |

mm |

|

J |

Lower walking body width |

3340 |

3340 |

mm |

|

K |

Total width |

3522 |

3522 |

mm |

|

L |

Total length |

12040 |

11380 |

mm |

|

M |

Total arm height |

3450 |

3900 |

mm |

|

N |

Running range height |

1150 |

1150 |

mm |

|

Note: Does not include track plate flange height |

||||

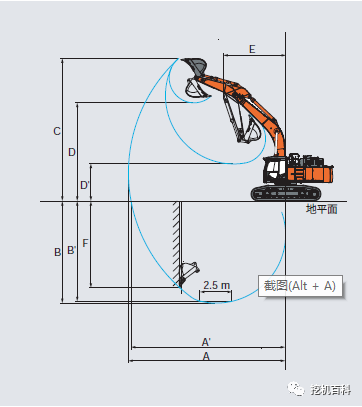

8. Operational scope:

|

ZX520LCH-6A |

ZX520LCH-6A(BE) |

|||

|

A |

Maximum excavation radius |

12060 |

10820 |

mm |

|

A' |

Maximum excavation radius (on the ground) |

11860 |

10520 |

mm |

|

B |

Maximum excavation depth |

7860 |

6290 |

mm |

|

B' |

Maximum excavation depth (2.5 m plane) |

7700 |

6040 |

mm |

|

C |

Maximum cutting height |

10980 |

10790 |

mm |

|

D |

Maximum removal height |

7560 |

7280 |

mm |

|

D' |

Minimum uninstall height |

2870 |

3170 |

mm |

|

E |

Minimum rotation radius |

4840 |

3920 |

mm |

|

F |

Maximum vertical digging depth |

7170 |

4740 |

mm |

|

Note: Does not include track plate flange height |

||||

Stable and reliable, high quality

1. Reliable and durable environmental technology, overseas sales of more than 100 thousand units, domestic users test more than 40,000 hours.

-

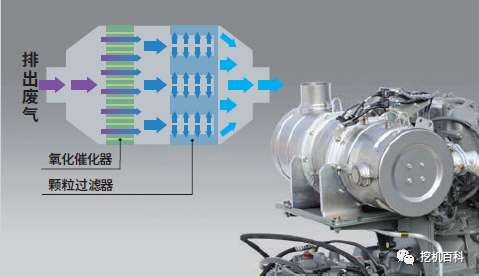

The new 6A engine is equipped with a post-processing filter, which reduces atmospheric pollution by capturing PM particulates from the exhaust gas and burning them efficiently in the filter. Waste gas emissions are reviewed by the Fourth National Emissions Standard.

-

The interior of the reprocessing filter is made of high-end ceramic materials, which are durable.

-

Using the same environmental protection technology Hitachi construction products have been sold overseas, mature and stable performance, excellent quality and reliable.

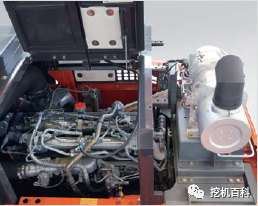

2. Core technologies are upgraded, high-quality genes are more reliable

-

Core components such as engines, hydraulic pumps, and main control valves are imported to be more durable and maintain value.

-

The oil sprayer has been completely upgraded, the spray needle moves more smoothly and is more durable;

-

DLC coating (similar to diamond carbon film) with hardness close to diamond is used on high-pressure oil pump and injector, which has high wear resistance and low friction;

-

The fuel road is positive pressure type, effectively preventing air from entering the high pressure pump and improving the durability of the high pressure oil pump and oil sprayer.

-

It is fitted with a wax-resistant oil road to prevent the engine from stopping after starting work when it is cold because of fuel wax.

-

The electrical and mechanical energy of alternating current generation increased, and the battery was not easy to lose power, enhancing the engine's start-up performance.

-

The radiator is increased, and the thermal balance performance is better.

3. Enhanced overall design to ensure stable attendance

-

The front-end working unit uses internal welding and complete welding, and further optimizes the welding process to ensure long-term stable operation;

-

The weight bearing area of the boom is strengthened, and the supporting part of the arm is strengthened, which improves the overall strength and is more suitable for high intensity mining operations.

-

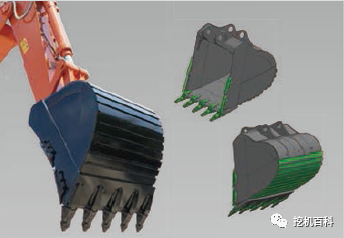

The new rock bar, bar teeth / cogs / side teeth are designed in a new way to reduce drag and be more efficient. The back of the shovel has a double-sided arc, making it more suitable for excavation work. Adding abrasion-resistant plates to the bottom of the shovel improves durability.

-

Standard reinforced double-barred track plate, more suitable for mines and gravel sites;

-

The car adopts high strength LC lengthening structure to improve the stability of the whole machine. At the same time, the removal duct is standardized, which effectively protects the removal hoses and the central steering joint.

High yield and efficiency

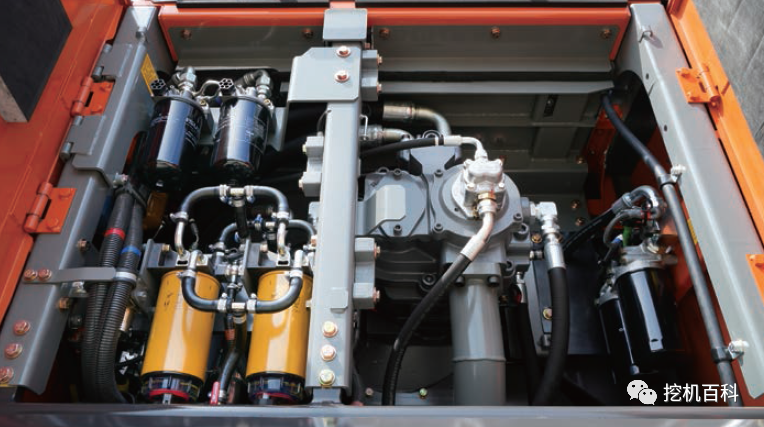

1. New artificial intelligence operates the hydraulic system, controls upgrade, and works efficiently

-

The new HI0SV artificial intelligence hydraulic system is best controlled, smooth, fast and comfortable for composite work, and effectively reduces hydraulic pressure loss, greatly improves energy utilization, and improves operation efficiency and fuel efficiency.

-

The new engine has significant increases in power and torque, efficient matching of the engine and hydraulic system, small power loss and consistently high output;

-

The power exertion unit achieves a rapid pressure increase with one click, and the excavator power is instantly increased, which is especially suitable for excavation on hard foundations.

-

Offering arm-to-arm mode options, both strong and comfortable modes can be chosen according to the load stress on the front-end work unit, helping to improve operation efficiency, improve operation comfort and extend the service life of the components.

-

Multiple power modes meet different energy efficiency requirements.

-

The attached replacement support system, through a multifunctional monitor, can easily enable valve switching and flow setting, which improves operation efficiency.

2. Using cutting-edge technology to achieve efficient fuel savings

-

The high-voltage co-rail system is used, and electronic control is used to achieve precise control of the injection time and amount of injection, improving fuel efficiency.

-

The fuel sprayer has been comprehensively upgraded, increasing the maximum injection pressure and reducing the diameter of the jet, which double helps improve the fuel vaporization effect and improve fuel efficiency.

-

Variable Section (VGS) turbocharger is adopted to ensure that the engine can be steadily pressurized regardless of low speed or high speed, thereby improving fuel efficiency;

-

The new hydraulic system increases pump capacity and improves pump efficiency, which in turn improves fuel efficiency.

Comfortable operation, easy and safe

1. A comfortable driving experience

-

The driver's room has spacious space and excellent views;

-

The monitor switch, air conditioner switch, etc. are centrally set in the right console, making the operation easier;

-

Standard air suspension seats, with seat heating function, greatly improve comfort;

-

Equipped with a lightweight steering handle, it does not easily fatigue even during long hours of operation;

-

Equipped with bluetooth recorder, USB charging port, so that the operation is enjoyable;

-

The driver's room is supported by a hydraulic elastic seat that absorbs shock and vibration;

-

The pressurized cab effectively avoids the entry of dust and particles.

2. Safe and reliable driver's room

-

Using CRES (central pillar reinforced) driving room, the top shield meets the OPG II standard, plus the lower protective net of the front window, multiple protection to make the operation more secure;

-

The automatic lock function of the operating handle can effectively prevent the occurrence of machine error in an unconscious state;

-

In the event of an unexpected engine failure, the engine can be quickly shut down by the emergency shutdown switch;

-

Equipped with a power cutoff switch, it can prevent battery loss and line failure during downtime or long-term use;

-

The top of the driving room, both sides of the boom and the platform are equipped with LED working lights, making night work safer.

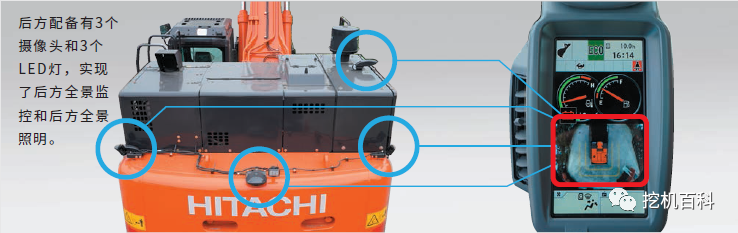

3. Multifunction supervisory control system

-

It is composed of a large color LCD screen, a controller and a rear camera. The menu is selected by a multi-function controller on the control panel.

-

Supports attachments replacement systems and a crushing hammer operating hourtable.

-

Support for multilingual languages.

-

Regenerative monitoring and rear view monitoring have been added.

Easy maintenance

-

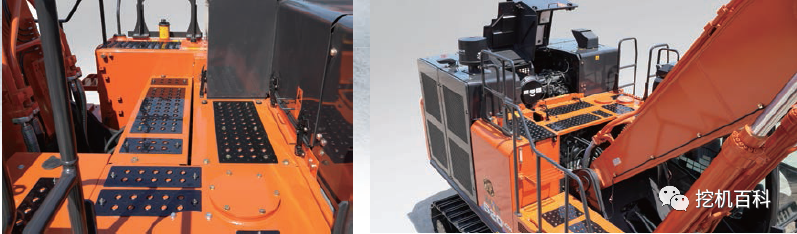

New large armrests provide safer protection for everyday maintenance;

-

The radiator has a new and larger design, and the radiator door has a brand new design, which improves maintenance efficiency;

-

The main fuel filter and the pre-filter adopt double layer 2μm and double layer 5.5μm filter elements respectively, which have high filtration accuracy and prolong the maintenance period.

-

Hydraulic fans with a reverse function not only improve the heat dissipation performance, but also facilitate the cleaning of radiators, oil coolers, and medium chillers.

-

Use a closed expansion tank, which does not require frequent injection of coolant;

-

Use a maintenance-free battery and a maintain-free air prefilter.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE