VOLVO EC360 Classic inheritance, brand new upgrade

VOLVO EC360 Classic inheritance, brand new upgrade

Large excavator

EC360 CN4

Configuration parameters

Standard: ● Option: ○ Reference value: * To be refined: /

1. Performance parameters:

|

force |

Traction force |

261 |

kN·m |

|

Bucket Digging Force - ISO |

218 |

kN |

|

|

Bucket Rod Digging Force - ISO |

197 |

kN |

|

|

Rotation torque |

126.2 |

kN·m |

|

|

speed |

Reverse speed |

10.3 |

r/min |

|

行走高速/低速 |

5.1/3.3 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

° |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Volvo D8M |

|

|

rated power |

220/1600 |

kW/rpm |

|

Maximum torque |

1400/1400 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

DOC+DPF+SCR |

3. Hydraulic system:

|

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

Double turnaround |

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*288 |

L |

|

The overflow valve settings: |

||

|

The working oil road |

33.3 |

MPa |

|

Turning the oil road |

27.9 |

MPa |

|

Walking the oil road |

33.3 |

MPa |

|

Leading oil road |

/ |

MPa |

|

Power exertion |

36.3 |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

6450 |

mm |

|

Fighting clubs |

2850/3200 |

mm |

|

The shovel fighter looks |

1~2.53(2.0/1.8) |

m³ |

5. The chassis system:

|

Weight of weight |

/ |

kg |

|

Number of trackpads - one side |

/ |

section |

|

Number of cogs - one side |

2 |

individual |

|

Number of support wheels - one side |

8 |

individual |

|

Running board width |

600 |

mm |

|

Chainrail steering agency - single side |

2 |

individual |

6. Amount of oil and water added:

|

Fuel tank |

580 |

L |

|

Urin boxes |

50 |

L |

|

Hydraulic system |

433 |

L |

|

Hydraulic fuel tank |

183 |

L |

|

Engine oil |

30 |

L |

|

Antifreeze Solution |

44 |

L |

|

Walking brake gear oil |

2*6.8 |

L |

|

Reverse gear oil |

6 |

L |

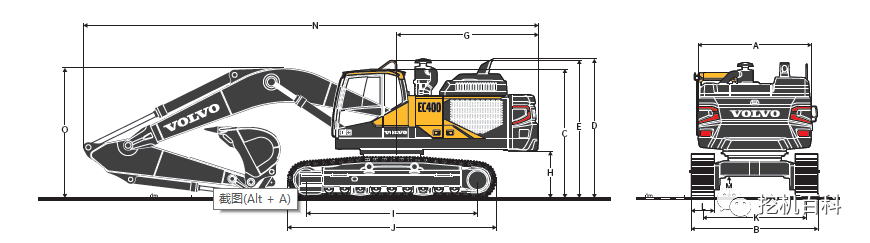

7. Form factor:

|

A |

Total upper structure width |

2890 |

mm |

|

B |

Total width |

3190 |

mm |

|

C |

Total height of the driver's room |

3175 |

mm |

|

D |

Total height of engine cover |

2990 |

mm |

|

G |

Tail pivot radius |

3585 |

mm |

|

H |

Weight-to-earth gap * |

1170 |

mm |

|

I |

Wheel spacing |

4020 |

mm |

|

J |

Track length |

4945 |

mm |

|

K |

Track length |

2590 |

mm |

|

L |

Trackboard width |

600 |

mm |

|

M |

Minimum distance from the ground * |

500 |

mm |

|

N |

Total length |

11297 |

mm |

|

O |

Total arm height |

3610 |

mm |

|

*: Does not include track plate flanges height |

|||

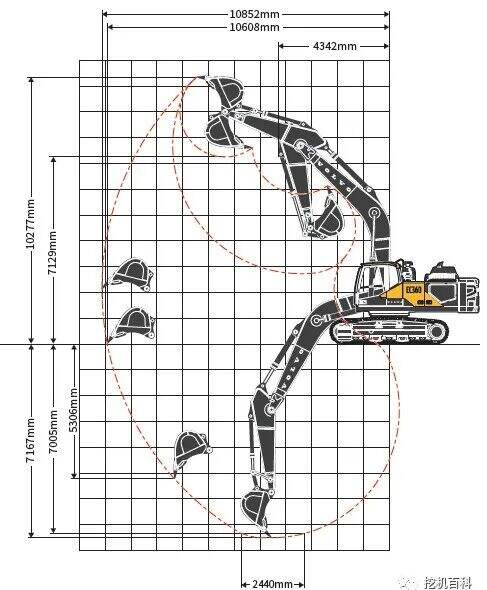

8. Operational scope:

Excellent performance

1. Time-tested engine technology.

-

Since 2014, Volvo engines that meet the Tier 4 standards have been tested worldwide. The technology of this engine has been validated and improved for almost 10 years, with exceptional levels of quality, reliability and efficiency, and is fully trustworthy.

2. Meeting operational needs

-

Operators can easily select and adjust a number of functions based on personal preferences and work tasks, including arm / pivot and arm / walk prioritization, giving one function priority over another.

-

The operator can also easily adjust the pace of the arms' decline, making it ideal for fine job tasks requiring precise control.

3. Increase productivity and reduce fuel consumption

-

The EC360 has an excellent level of productivity, with about 10% more fuel efficiency.

-

The new generation electro-liquid control system provides flow on demand, reducing internal losses in the hydraulic circuit, while the Volvo D8M engine has a rated speed of 1600 rpm and can also produce higher torque at low speeds.

-

Automatic engine idling and automatic engine downtime further reduce unnecessary fuel consumption.

4. Strong operational capability

-

Work can be carried out using a range of factory-supplied accessories such as Volvo shovels and crushing hammers.

-

Volvo accessories fit perfectly with your machine to help you get things done with greater efficiency, productivity and performance.

Switching more smoothly

1. Custom Control Modes

-

The monitor makes it easy to customize various settings, including selecting the preferred control mode and manipulating the handle response, to prepare for construction work. -

The operator can use the L8 joystick to create a hydraulically first fast mode by setting up another fast mode with the "Long Push" function on the joystick.

2. The famous driver's room

-

The renowned Volvo Care Drive Room, the ROPS Drive Room exceeds the industry standards for such machines, with low noise and low vibration, and the operator can experience greater comfort.

-

The driver's room has good visibility and can be further enhanced with a Volvo panoramic camera system.

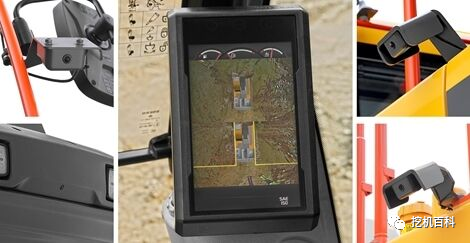

3. More precise

-

Dig Assist uses a 10-inch Volvo Co-Pilot display screen for maximum efficiency.

-

The system is equipped with a set of intelligent applications that optimize the excavation process, including 2D, 3D, In Field Design and On-Board Weighing.

4. More Control

-

With Volvo Active Control features, including the movement control of automatic arms and shovels, the job is easier, the dig is more accurate and the speed is doubled.

-

Simply set the slope from the Volvo Co-Pilot display and press a button to get to work - all with a joystick control.

clear and simple

1. Walk safely.

-

Industry-renowned features (e.g. bolted anti-skateboards, high visibility handrails and guard rails) further ensure a high level of safety for machine movement. -

For greater convenience, a foldable cab entrance steps and side aisles are optional for ease of transport.

2. A vision of leading industry standards

-

The low shield design of the machine ensures an excellent field of view, making it easier for operators to observe the side and rear of the machine as they operate.

-

Rear-view and side-view cameras help to expand the direct view.

3. Volvo Smart Display System

-

The optional Volvo Smart Imaging System uses front, rear and side cameras to provide a real-time view of the machine, ensuring it rotates more safely while at work, especially in narrow spaces.

4. More Safety and Security

-

With the help of Volvo Active Control, operators can easily set turn fences, height limits and depth limits through the Volvo Assisted Driving System. -

This helps the machine to stay away from side obstacles, hanging obstacles (power lines, etc.) and various hazards underground (such as pipes, cables, etc.).

Easy to repair

1. Perfectly designed and durable

-

The rugged excavator features a robust design with floor protection and reinforced doors and hinges to achieve high efficiency even under harsh operating conditions.

2. Engine Protection

-

The engine delayed downtime function allows the turbocharger to remain in optimal working condition for a long time.

-

To avoid overheating, when the turbocharger cools to a suitable temperature, the smart setting turns off the machine in time, or it can be set by the operator to turn it on automatically.

3. Easily monitor the state of your machine

-

The new generation of vehicle communication hardware PSR brings a new upgraded car networking service experience.

-

You can view the real-time working condition of the equipment through the Volvo + wisdom cloud platform or the Volvo construction equipment APP, Wo peace of mind report, maintenance / alarm reminder, etc.

-

The Volvo Maintenance Hours Centre provides 24 / 7 machine monitoring, provides monthly reports, and notifies you when preventive maintenance measures need to be taken.

4. Maintain normal operation at all times

-

Higher productivity and machine uptime are maintained through the use of easy-to-access, tested and certified Volvo Pure Parts, all of which are supported by Volvo Warranty.

-

Volvo dealers can offer flexible maintenance and repair services or planned maintenance to help you keep your machine up and running and extend the life of your machine.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE