VOLVO EC220 Classic inheritance, brand new upgrade

VOLVO EC220 Classic inheritance, brand new upgrade

Medium-sized excavator

EC220 CN4

1. Performance parameters:

|

force |

Traction force |

183 |

kN·m |

|

Bucket Digging Force - ISO |

153 |

kN |

|

|

Bucket Rod Digging Force - ISO |

111 |

kN |

|

|

Rotation torque |

83 |

kN·m |

|

|

speed |

Reverse speed |

11 |

r/min |

|

行走高速/低速 |

5.6/3.5 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

° |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Volvo D6J |

|

|

rated power |

129/1800 |

kW/rpm |

|

Maximum torque |

850/1350 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

DOC+DPF+SCR |

3. Hydraulic system:

|

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

|

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*207 |

L |

|

The overflow valve settings: |

||

|

Execute a hydraulic circuit |

34.6/36.3 |

MPa |

|

Turning the oil road |

27.9 |

MPa |

|

Walking the oil road |

34.3 |

MPa |

|

Leading oil road |

/ |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

5700 |

mm |

|

Fighting clubs |

2900 |

mm |

|

The shovel fighter looks |

1.4 |

m³ |

5. The chassis system:

|

Weight of weight |

4200 |

kg |

|

Number of trackpads - one side |

/ |

section |

|

Number of cogs - one side |

2 |

individual |

|

Number of support wheels - one side |

8 |

individual |

|

Running board width |

600 |

mm |

|

Chainrail steering agency - single side |

2 |

individual |

6. Amount of oil and water added:

|

Fuel tank |

360 |

L |

|

Urin boxes |

30 |

L |

|

Hydraulic system |

250 |

L |

|

Hydraulic fuel tank |

140 |

L |

|

Engine oil |

25 |

L |

|

Antifreeze Solution |

14 |

L |

|

Walking brake gear oil |

2X3.5 |

L |

|

Reverse gear oil |

6.8 |

L |

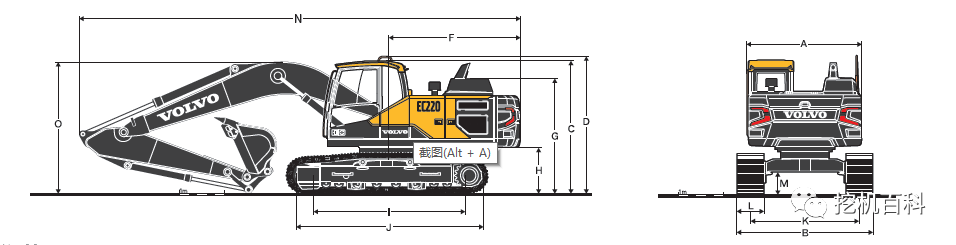

7. Form factor:

|

A |

Total upper structure width |

2500 |

mm |

|

B |

Total width |

2990 |

mm |

|

C |

Total height of the driver's room |

2929 |

mm |

|

D |

Total armrest height |

3046 |

mm |

|

F |

Tail pivot radius |

2850 |

mm |

|

G |

Total height of engine cover |

2600 |

mm |

|

H |

Weight-to-earth gap * |

1011 |

mm |

|

I |

Wheel spacing (drive and guide wheels) |

3660 |

mm |

|

J |

Track length |

4460 |

mm |

|

K |

Track length |

2390 |

mm |

|

L |

Trackboard width |

600 |

mm |

|

M |

Minimum distance from the ground * |

460 |

mm |

|

N |

Total length |

9690 |

mm |

|

O |

Total arm height |

2940 |

mm |

|

*: No track plate teeth |

|||

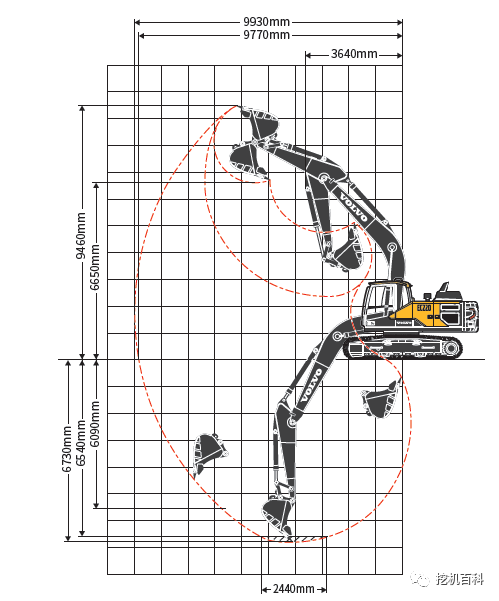

8. Operational scope:

1. Fuel efficient mode.

-

The machine uses technology unique to Volvo that combines the operation mode with the throttle control device for higher performance.

-

When the driver selects a certain operating mode: I (idle), F (fine), G (normal), H (heavy) and P (power), the system has set the corresponding speed to achieve greater efficiency. The ECO mode further improves fuel efficiency by about 5% and does not lose any performance in most operating conditions.

2. Stronger control, lower fuel consumption

-

Optimized hydraulic systems work in concert with fully electronic control systems and advanced ECO mode to match engine power, reduce power loss and improve operation and response speed.

-

The EC220 crawler excavator's boom rotary priority valve further improves operability and is ideal for truck loading.

3 Playing its full part

-

With smart engine capabilities, unnecessary fuel consumption can be reduced, operating costs reduced and the environmental impact reduced, so that every drop of fuel makes a difference.

-

If the controller is not activated for a preset period of time, the engine automatic idling function reduces the engine speed to idling.

-

If the machine is inactive for a preset period of time, the engine automatic shutdown function automatically shuts down the engine.

4. Stay up to date on what's happening

-

The combination of machine capabilities with Volvo services helps drivers and owners monitor fuel usage, maximize efficiency and further reduce operating costs.

-

The fuel meter displays real-time fuel consumption and average fuel usage information to keep you up to date.

-

A fuel efficiency report provides a clear picture of fuel consumption in a fleet, on site or on a single machine and helps identify areas where fuel efficiencies can be improved.

1. Excellent view.

-

The operator is relieved of worries thanks to the slim cab column, optimized LED work lights, large glass area and rear-view camera.

2. A new monitor

-

Color LCD monitors have a larger screen, a more intuitive layout, and can display more information. The screen is anti-glare and can be tilted to make it more convenient to use.

3. Safety First

-

Every Volvo machine has been designed with safety in mind, and the EC220 has a ROPS driving room, emergency engine shutdown and laminated front glass to provide better operator protection.

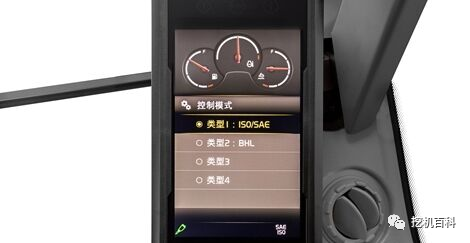

4. Custom Control Mode

-

By customizing settings or easily selecting the preferred control mode from the monitor, the machine is ready to work at any time.

-

The operator also has the option to easily manipulate a function by manipulating a shortcut switch on the handle.

1. Experienced engine technology

-

Since 2014, Volvo D6 engines that meet the National IV standards have been validated worldwide.

-

Thanks to nearly 10 years of technical testing and improvement, this engine delivers a higher level of quality, reliability and efficiency that customers can rely on.

2. Long-lasting performance.

-

A range of standard protection features such as filters, electronic warning sensors and automatic protection systems help keep the machine in optimal working condition.

-

When the turbocharger cools to the right temperature, the smart engine delayed downtime function turns the machine off, further enhancing the engine's durability and reliability.

3. Long lasting.

-

With a robust and durable design, the EC220 tracked excavator's optimized arms and arms use internal panels to disperse stress from high-pressure areas, allowing the machine to withstand greater operational strength and a longer service life.

-

The optimized X-shaped lower frame provides even weight distribution, while the optimized chassis provides excellent traction.

4. Strong operational capability

-

The EC220 can be fitted with a wide range of Volvo dips to maximize productivity and profitability, making it ideal for digging and reprocessing operations in a variety of operating conditions.

1. Production is uninterrupted

-

Longer maintenance cycles reduce operating costs and increase uptime.

-

The 5,000-hour hydraulic fluid replacement interval and the 2,500-hour lubrication filter replacement interval minimize operational disruptions, and the increased fuel tank capacity contributes to longer uninterrupted production.

2. Machine monitoring is more convenient

-

Pulse, a new in-vehicle communication system, can maximize machine uptime and reduce maintenance costs.

-

Check your machine's health with Volvo ActiveCare.

-

The Volvo Maintenance Hours Centre will provide 24 / 7 machine monitoring and notify you when preventive maintenance measures are required.

3. We are fully committed to your service.

-

Volvo's range of services meets your needs, keeping your machines running efficiently through forward-looking solutions and a network of technical experts.

-

Provide services such as deferred insurance and customer care maintenance checks to ensure the efficient operation and excellent performance of the machines.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE