SANY SY26U Classic inheritance, brand new upgrade

SANY SY26U Classic inheritance, brand new upgrade

Tiny excavators

SY26U

Summary

Small and strong. Build an elf.

The SY26U is a 2-3T mini excavator produced by Sany Heavy Machinery. It is small in size, has no tail rotation,and can adapt to a variety of narrow working conditions。It can be equipped with a variety of tools and configurations to achieve one machine for multiple purposes, thus creating greater value for customers.

SY26U is upgraded around " new power " , " new shape " , " new technology " . It is flexible , easy to control , safe and environmental protection ,easy to maintain , suitable for small projects such as house renovation , ditch digging , landscaping , vegetable greenhouse , farmland orchard .

Main technical specifications:

Power: 14.6/2400 kW/rpm; 15. 4/2400kW/rpm

Machine weight: 2680kg

Bucket capacity: 0.07 m3

Configuration parameters

Standard: ● Option: ○ Reference: *

Bucket digging force 27.9kN

Arm digging force 14.2kN

Rotation speed 9 r / min

Walking speed 4.5 / 2.6 km / h

Slope ability 70 per cent (35 per cent)

Ground specific voltage 26kPa

Powertrain:

Engine 3 TN80F (Yanmar) / D1105 (Kubota)

Frontal fixed power 14.6kW / 2400rpm (Yanmar)

15.4kW2400rpm (Kubota)

Displacement 1.267 L (Yanmar)

Reference number: 1.123L (Kubota)

Emissions Standards Country IV

Hydraulic system:

Technical routeload-sensitive flow distribution system

The arms and arms are:

2100mm boom

1300mm rod

●0.07 m³ 铲斗

○0.06 m³ 铲斗

The chassis system and structure:

● 300 mm track (steel / rubber)

• 4 axles on each side

● 1 chain wheel on each side

Oil and water injection:

Fuel Tank 34 L

Hydraulic Tank 27 L

Engine oil 3.4 / 1.6 L (Yanmar) / 3.5 / 1.8 L (Kubota)

Antifreeze water 2.4L / oil 1.7L

Final drive 2 × 0.6L

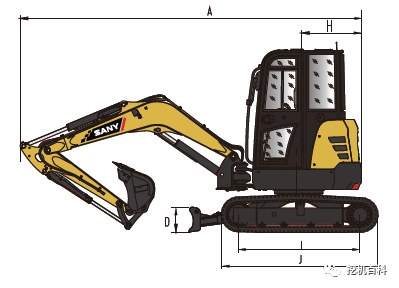

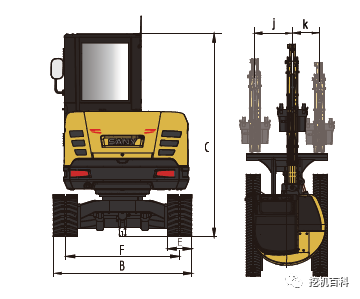

Form factor:

A. Total transport length 4285 mm

B. Total width 1550 mm

C. Total transport height 2430 mm

D. Bulldozer height 300 mm

E. Standard track width 300 mm

F. Gauge (transport / operation) 1250 mm

G. Minimum ground clearance 290 mm

H. Rear radius of gyration 775 mm

I. Track grounding length 1560 mm

J. Track Length 2005 mm

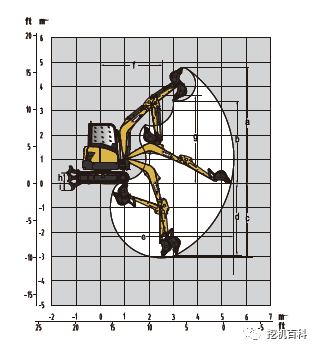

Operational scope:

A. Maximum excavation height 4410 mm

B. Maximum unloading height 3100 mm

C. Maximum excavation depth 2820 mm

D. Maximum vertical arm excavation depth 2585 mm

E. Maximum excavation radius 4850 mm

F. Minimum radius of gyration 2110 mm

G. Maximum height at minimum radius of gyration 3200 mm

H. Maximum ground clearance of bulldozer lift 360 mm

I. A maximum depth of 330 mm for bulldozing

J. Arm left deflection distance 765 mm

K. Right deflection distance of boom 540 mm

New upgrade - fuel efficient

1. Powertrain:

-

SY26U can provide two kinds of power solution, both meet the national four emission standards, powerful, reliable and durable, to meet the diverse power needs of customers.

2. Hydraulic system:

-

Powered by well-known brands of pumps and valves, the design has been developed according to customer needs, with prominent advantages such as "high reliability, small pressure loss, and smooth compound motion."

-

The auxiliary valve electric control upgrade makes auxiliary valve control more convenient, improves efficiency, and helps customers create greater value.

3. A non-polar throttle speeding system

-

The diggers can work at any desired speed, making operational personalization and productivity a perfect combination.

Optimization of structural components - durability

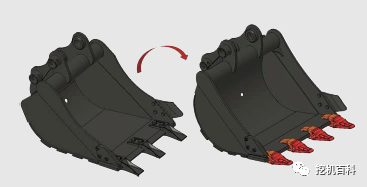

1. Total upgrade of shovels and suspension racks

-

The shovel escalated, armed to the "tooth." Bucket capacity increased from 0.06 m3 to 0.07 m3. The cocked teeth were increased from 3 to 4 teeth and upgraded from bolt to solder, which is more efficient, has a longer life and is easier to replace.

-

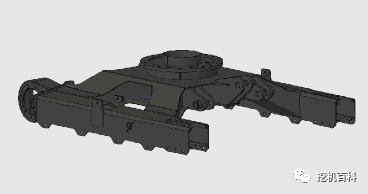

By analyzing the stability of the entire machine, it is designed to have a single-sided structure of four heavy wheels and two bearing-type chain wheels to eliminate the risk of chain brake.

2. Standard hydraulic lock

-

Increase the hydraulic lock on the bulldozer hydraulic oil road and the rotary oil tank to further reduce the oil tank sediment and improve customer satisfaction.

Upgrade the cab - flexible and easy to control

1. The canopy is easier to disassemble:

-

Improve comprehensive disassembly of the cape. With 8 sets of fasteners, the disassembly of the convertible can be completed, and the low-level operation environment can be efficiently dealt with.

2. Floor mats raised:

-

The newly developed high floor pad, the floor pad to the seat installation surface of the distance compared to the three countries reduced by 20mm, improve operating comfort. The floor mat is simple in pattern and at the same time is slippery resistant, making it easy to clean.

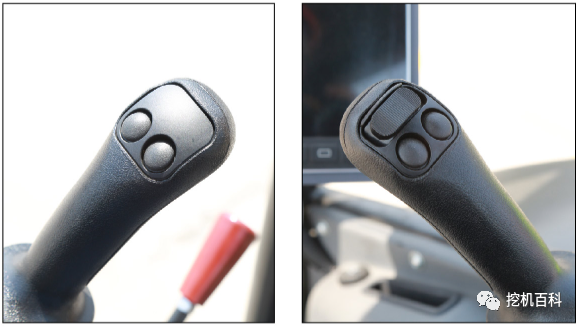

2. Multifunctional handle upgrades:

-

Electrical system upgrade: The earth shovel handle incorporates high and low speed switching switches, the waterproof and dust prevention of the line beam throughout the vehicle is upgraded, and the electrical system is optimized and upgraded to bring a more enjoyable operation experience to customers.

-

Upgrade of the electric control of the cutter: The right hand handle was upgraded to a multifunctional handle with integrated cutter function.

-

The third auxiliary pipeline control mode is a foot pedal, and the fourth machine is controlled by a hand handle, which is more flexible and convenient.

3. Squeezing and noise reduction Smart comfort:

-

The silencer was optimized, and the overall noise was reduced by 1 decibel compared to the national three.

-

Equipped with a high-end smart display, it integrates display, query, alarm and other functions.

-

Standard shock-reduction seats are comfortable to enjoy and can effectively alleviate work fatigue.

4. Multifunctional configuration:

-

New storage box functions are added to facilitate storage. Set 12V power socket, mobile phone seat and cup seat, complete configuration, more people.

Trinity Digging - A Multi-Faced Expert

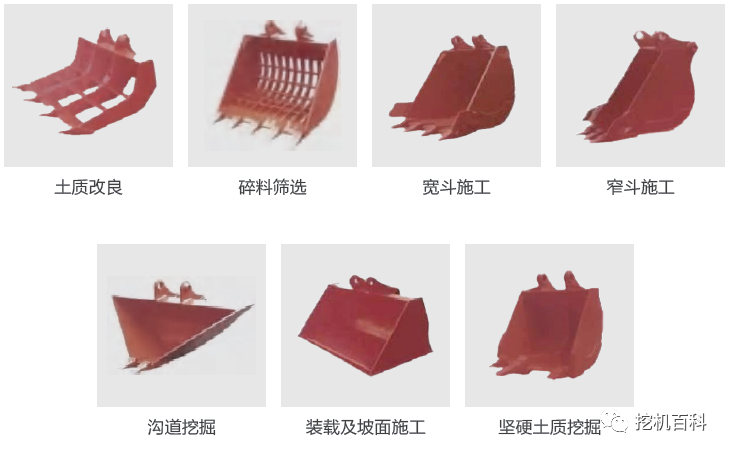

1. Multiple uses of a single machine

-

SANY Micro Excavator is equipped with standard auxiliary pipeline and cut-off valve, which can be directly installed with breaking hammer and other auxiliary tools. Legendary Weapons of China are proficient in everything.

-

Sany Min digging originally had narrow trenches, wide trenches, weed rakes and other tools, with different working conditions and different tools, and higher efficiency.

2. Applicable scenarios:

-

Standard auxiliary pipes and cut-off valves can be directly installed as auxiliary tools such as crushing hammers, and originally adapted narrow bore, wide bore, and weed brushes, with different tools and greater efficiency. Housing renovation, landscaping, vegetable sheds, trench excavation and soil improvement can be done

Functional setup

Standard: ● Option: ○

Engine:

-

D1105

-

12V / 1.4kW Starter Motor

-

12V-60A Hair Motor

-

Dry double filter air filter

-

Cylindrical lubrication oil filter

-

Bulk fuel filter

-

The engine warms up

-

Oil cooler

-

Heat heater with protective net

-

Fan curtain

-

Isolated engines

-

Plastic fuel tank

The lower walking body:

-

Walking motor pads

-

Performance-oriented tightening of institutions

-

drive wheel

-

Double shoulder support wheel

-

300mm wide steel tracks

-

The bottom panel of the lower carriage frame

-

High-strength rolling support

-

Ground plates

Hydraulic system:

-

Energy Storage

-

Road 1 auxiliary oil road

-

Hydraulic oil cooling

-

Automatic reverse braking

-

Armed cylinder protection

-

Continuous traffic

-

27L Hydraulic Oil Tank

Front-end working devices:

-

Welding joints

-

2100mm fully welded box boom

-

1300mm fully welded box type

-

Standard bucket: 0.07 m3

-

Optional bucket: 0.06 m3

-

Welding a rotary joint

The convertible:

-

Feet boards, floor mats

-

Speakers, rear view mirrors

-

Safety belt

-

Drinking cup seat

-

Lead control cutting rod

○ Driver's Room

Electrical control system:

-

Engine start protection function

-

All-in-one display controller

-

Fuel, water, oil temperature, pressure supervisory control system

-

Fault self-diagnosis function

-

High-capacity batteries

Others:

-

Lockable hood

-

Manual Butter Gun

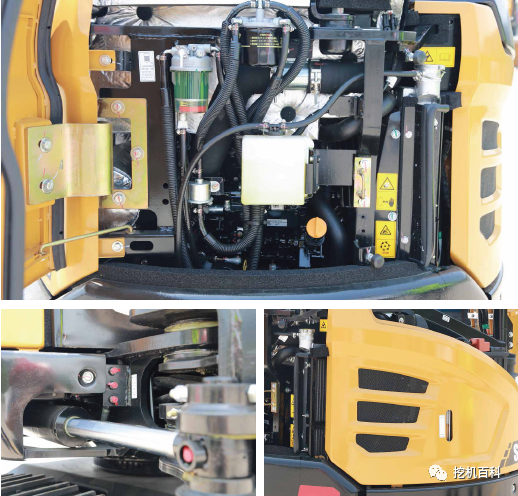

Easy maintenance

-

The wide area covering is opened by means of opening, and after opening it can stand on the ground for daily maintenance and maintenance, and the repair is convenient and close to.

-

Air filters, fuel filters and oil filters are within easy reach, and maintenance is very convenient.

-

Lubricating oil injection: The butter injection mouth on the steering support is centrally arranged to make lubrication and maintenance more convenient.

-

Heat cooler: There is a special safety net on the outside, and dirt is kept out of the outside of the safety net. Simply remove the safety network and clean it.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE