SANY SY35U Classic inheritance, brand new upgrade

SANY SY35U Classic inheritance, brand new upgrade

Tiny excavator

SY 35U

Summary

High-end configurations versatile

SY35U is a 3-4T class mini excavator product created by Sany Heavy Machinery . With its unique shape andhigh-end design concept , it has won international recognition and successfully won the " China Design Red Star Award " and the " Golden Point Design Award . "

SY35U is upgraded around " new power " , " new shape " , " new technology " , with " excellent performance , ultra-highefficiency , ultra-long life , ultra-comfortable " and other characteristics , can adapt to the needs of different countries and customers .

Main technical specifications:

Power: 20.2 / 2200 kW / rpm

Machine weight: 3780kg

Bucket capacity: 0.12 m3

Configuration parameters

Standard: ● Option: ○ Reference: *

Bucket digging force 30.4kN

Arm digging force 18.2kN

Rotation speed 9 r / min

Walking speed 4.2 / 2.4 km / h

Slope ability 70 per cent (35 per cent)

Ground specific voltage 32 kPa

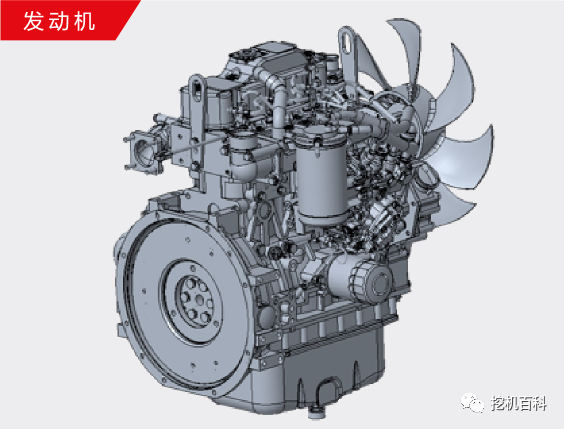

Powertrain:

Engine Yanmar 3 TNV88

Frontal fixed power 20.2kW / 2200rpm

Displacement 1.642L

Emissions Standards Country IV

Hydraulic system:

Technical routeload-sensitive flow distribution system

The arms and arms are:

●2540 mm boom

● 1400 mm rod

○ 1650mm rod

●0.12 m³ 铲斗

The chassis system and structure:

● 300 mm track (steel / rubber)

• 4 axles on each side

● 1 chain wheel on each side

Oil and water injection:

Fuel tank 50 L

Hydraulic Oil Tank 40 L

Engine oil 6 L

Antifreeze 3.8L

Final drive 2 × 0.7L

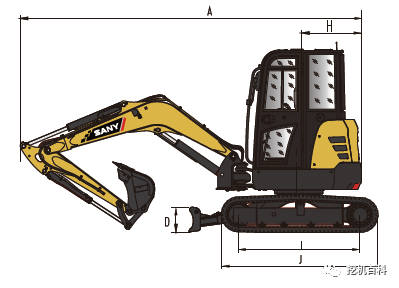

Form factor:

A. Total transport length 4910mm

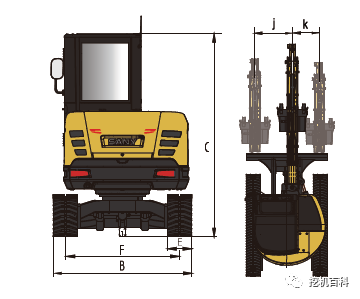

B. Total width 1720 mm

C. Total transport height 2555 mm

D. Bulldozer height 350 mm

E. Standard track width 300 mm

F. Gauge (transport / operation) 1420 mm

G. Minimum ground clearance 295 mm

H. Rear radius of gyration 860 mm

I. Track grounding length 1645 mm

J. Track length 2130 mm

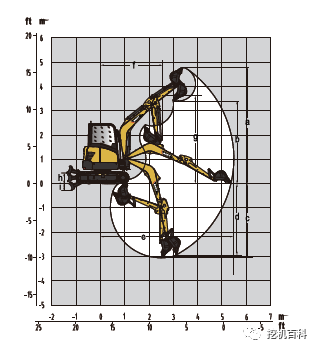

Operational scope:

A. Maximum excavation height 4865 mm

B. Maximum unloading height 3445 mm

C. Maximum excavation depth of 3,115 mm

D. Maximum vertical arm excavation depth 2640 mm

E. Maximum excavation radius 5480 mm

F. Minimum radius of gyration 2465 mm

G. Maximum height at minimum radius of gyration 3690 mm

H. Bulldozer lift Maximum ground clearance 375 mm

I. Maximum depth of bulldozer sinking 370 mm

J. Arm left deflection distance 765 mm

K. Right deflection distance of boom 605 mm

New upgrade - superior performance

1. Powertrain:

-

SANY custom Yanmar 3TNV88 engine, in line with the national IV emission standard, strong performance, efficient and reliable.

-

Engine advantages: Micromining is widely used and highly recognized by customers. It is durable, fuel efficient and easy to maintain.

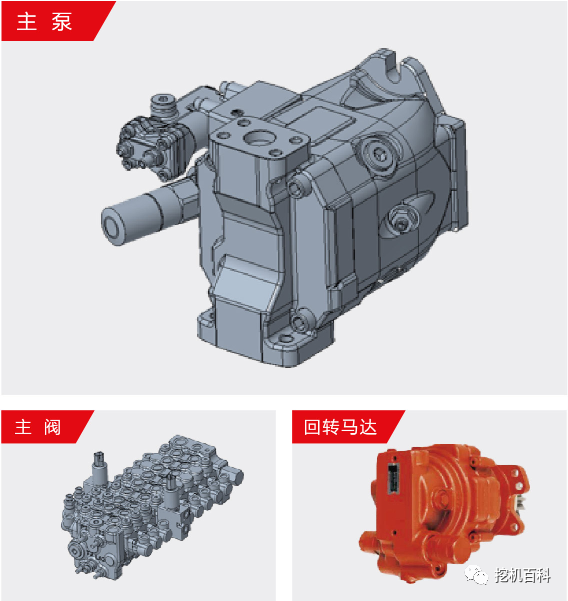

2. Hydraulic system:

-

Sany's custom pump and valve system, developed and designed according to customer needs, has prominent advantages such as "high reliability, small pressure loss, and smooth compound motion." The auxiliary valve electric control upgrade makes auxiliary valve control more convenient, improves efficiency, and helps customers create greater value.

3. Level speeding system

-

It can precisely match the power of commonly used stages to achieve optimal efficiency and fuel consumption.

New upgrade - superior performance

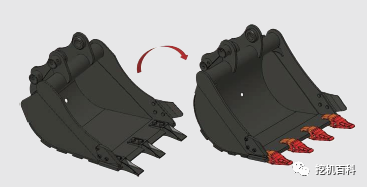

1. Total upgrade of shovels and suspension racks

-

Bucket optimization, bucket digging force 30.4kN, bucket digging force 18.2kN, digging efficiency increased by about 8%.

-

The braid is changed from vertical to horizontal, which is highly efficient, has a long life and is easy to replace.

-

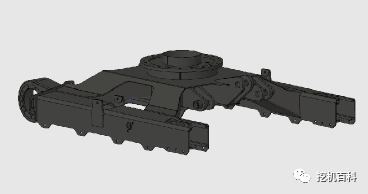

Scientifically and rationally allocate wheelbase to effectively improve the stability of the entire machine, and double bearing chain braces to eliminate the risk of chain brake.

-

The left and right beams of X-type lower frame and box structure have high strength and stiffness, and have excellent bending and torsion resistance, which can meet the requirements of different working conditions.

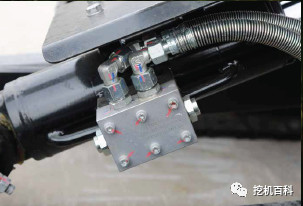

2. Standard hydraulic lock

-

Increase the hydraulic lock on the bulldozer hydraulic oil road and the rotary oil tank to further reduce the oil tank sediment and improve customer satisfaction.

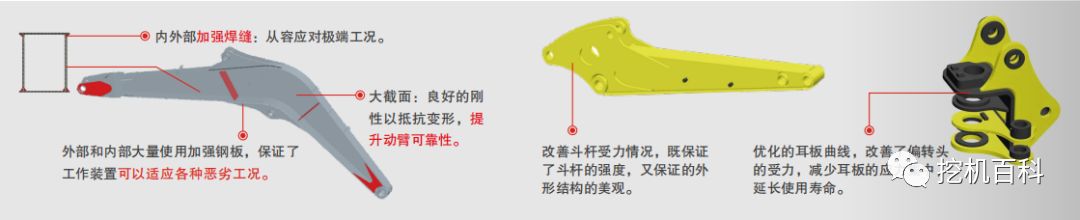

3. Armed arms upgrade

-

Use a larger cross sectional shape, better stiffness, and improve the resistance of the arms to deformation; Strengthened steel plate coaming is used in key parts to better adapt to harsh working conditions.

4. Upgrades to the cockpit and skewer head

-

By topological optimization so that the poles and pivots can both ensure strength and reduce weight, the lightweight working unit is a guarantee of fuel savings.

Upgrade the driver's room - a new experience

1. Optimization of the cab structure:

-

The steering wheel will not exceed the radius of the steering wheel when the driver's door is opened, taking full advantage of the tailless advantage.

2. The handle electric control upgrade:

-

The earth shovel handle incorporates a high and low speed switching switch, and the segmented wire beam is designed to facilitate maintenance.

-

The right hand handle was upgraded to a multifunctional handle with integrated breaking function.

3. Visual control upgrade:

-

Equipped with an extremely large 5-inch display control screen. A multifunctional application that combines display, query, alarm and other functions. In the background, the excavator's working data can be monitored and saved in real time.

-

GUI function adjustment and optimization, increase default mode, boot password, equipment registration, maintenance random code registration and lock machine functions.

-

Increase the engine ECU fault code, LS pressure sensor fault, idle and working mode power failure saving, buzzer continuous alarm, maximum start-up time 15S limit and other functions.

4. Air conditioning optimization:

-

The air conditioning ducts and vents are fully optimized to improve air conditioning effectiveness.

5. Quiet Comfort:

-

High backrest mechanical shock absorber seat, lower seat SIP height, more comfortable driving.

-

Optimize the silencer and wrap it with a thermal sponge.

-

The margin treatment of the covering was optimized, and the overall noise was reduced by 1 dB compared to the national three.

-

Automotive sealing and noise reduction technology is used. Indoor noise meets the latest environmental noise requirements, allowing you to have a more comfortable experience.

6. Human Design:

-

The driving room is equipped with a Bluetooth radio, cigarette lighter, ashtray, water cup seat, document bag, reading lamp, and coat and hat hooks, with a humane detail design that puts the user first.

Trinity Digging - A Multi-Faced Expert

1. Multiple uses of a single machine

-

Standard cab, optional convertible for low working conditions.

-

The two-way auxiliary pipeline is standardized, and various instruments are installed according to actual needs, which can easily cope with digging, grabbing, unloading, drilling, cutting, and crushing.

-

The auxiliary piping is equipped with ball valves to facilitate the customer to cut off the oil line when selecting the fittings to prevent pollution of the environment.

2. A variety of options:

-

Standard 1.4 m rod, optional 1.65 m long rod, larger operating range.

-

Rubber tracks can be optional to easily cope with municipal work conditions.

Functional setup

Standard: ● Option: ○

The lower walking body:

-

Walking motor pads

-

Performance-oriented tightening of institutions

-

drive wheel

-

Two supported chains

-

300mm wide steel track

-

The bottom panel of the lower carriage frame

-

High-strength rolling support

Hydraulic system:

-

Energy Storage

-

Road 1 auxiliary oil road

-

Hydraulic oil cooling

-

Automatic reverse braking

-

Armed cylinder protection

-

Continuous traffic

-

40L hydraulic oil tank

Front-end working devices:

-

Welding joints

-

2540mm fully welded box boom

-

1400mm Fully Welded Box Type, Patented Technology Bucket Rod

-

Standard bucket: 0.12 m3

-

Welding, patented deflection joint

Engine:

-

3TNV88 , China Stage 4

-

12V / 1.7kW Starter Motor

-

12V-55A Hair Motor

-

Dry double filter air filter

-

Cylindrical lubrication oil filter

-

Bulk fuel filter

-

Automatic idling system

-

The engine warms up

-

Oil cooler

-

Heat heater with protective net

-

Fan curtain

-

Isolated engines

-

50L plastic fuel tank

Driver's Room:

-

Soundproofed steel cab room

-

Strengthened light glass windows

-

4 silicone oil shock absorbers

-

Open front window

-

Rain wiper with a cleaning machine

-

Seat withdjustable armrests

-

Feet boards, floor mats

-

Speakers, rear view mirrors

-

Seat belt, fire extinguisher, safety hammer

-

Drinking cup seats, lanterns

-

Lead control cutting rod

-

Air conditioner

-

A coat and hat hook

Electrical control system:

-

Engine start protection function

-

All-in-one display controller

-

Fuel, water, oil temperature, pressure supervisory control system

-

Fault self-diagnosis function

-

Engine speed control system

-

A fault alarm light

-

Bluetooth radio for high power excavators

-

High-capacity batteries

-

Emergency engine shutdown control

-

Power main switch

Others:

-

Lockable hood

-

Manual Butter Gun

Easy maintenance

-

The wide area covering is opened by means of opening, and after opening it can stand on the ground for daily maintenance and maintenance, and the repair is convenient and close to.

-

Air filters, fuel filters and oil filters are within easy reach, and maintenance is very convenient.

-

Lubricating oil injection: The butter injection mouth on the steering support is centrally arranged to make lubrication and maintenance more convenient.

-

Heat cooler: There is a special safety net on the outside, and dirt is kept out of the outside of the safety net. Simply remove the safety network and clean it.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE