CAT 326 GC Classic inheritance, brand new upgrade

CAT 326 GC Classic inheritance, brand new upgrade

Medium-sized excavator

326GC

Summary

Not only does it have excellent productivity, but it also provides easy-to-use control devices.

The Cat326GC also offers a new comfortable cockpit, lower fuel consumption and longer service intervals (which reduce maintenance costs by up to 10 percent) - making an excavator that is durable and costs less per hour of operation.

-

Reliability of performance

GD 1.5m3 or HD 1.4m3 bucket for easy handling of more material

-

Up to 10% Lower maintenance costs

-

The cost per hour is low

Use new electric hydraulic main valves and pumps, smart modes and efficient cooling fans to reduce total costs.

-

Up to 10% reduction in CO2 emissions

Main technical specifications:

Power: 128.4kW

Machine weight: 24500 kg

Bucket capacity: 1.54 m3

Performance parameters, are being worked out. Stay tuned!

Configuration of the whole machine

Standard: ● Option: ○

Arm and pole:

●5.9 m(19'4" ) Stretch your arms

●2.95 m(9'8" ) Stretch the pole

Driver's Room:

Roll Protection Structure (ROPS)

Mechanically adjusted seats

● High resolution 8" (203mm) LCD touch screen monitor

○ Three-button manipulation grip

Electrical systems:

● Two 1000CCA maintenance-free batteries

● Programmable delay time LED work light

● LED chassis lights, left and right arm lights, driving room lights

Powertrain:

● Cat4.4 Dual Turbo Turbocharged Fuel Oil Engine

Two optional power modes

• One-touch low idle speed function with automatic engine speed control

Automatic engine idle shutdown

● -18 ° C (0 ° F) cold start capability

● 52 ° C (125 ° F) high temperature environment cooling capacity

Dual-core air filter with integrated prefilter

● Reverse electric cooling fan

Biodiesel with a maximum label of B20 can be used

○ -32 ° C (-25 ° F) cold start capability

Hydraulic system:

● Regenerative circuits for the arms and poles

Automatic hydraulic oil preheating

Automatic dual speed driving

● Arm and buttrest subduction valves

○ Slide Manipulating the Handle

○ Three-button manipulation grip

Combined flow / high pressure auxiliary circuit

○ Quick Connector Circuit for Cat Pin Gripper

The chassis system and structure:

●600 mm(24" ) Three-clawed ground teeth track plate

● Tether point on the base frame (according to ISO 15818)

● 4600 kg (10,141 lb) weight

Safety and protective devices:

● rear view camera

● Right rear mirror

• Ground engine stop switch

• Right handrails and handles

• Signal / alarm horn

Right-View Camera

○ Turnaround alarm

CAT Technology:

●Cat Product Link™

Hydraulically powered impact hammer

Remote refresh

Remote troubleshooting

Repair and maintenance:

● Centralized lubrication oil filter and fuel filter

● Planned analysis of oil sample (S · O · S) sampler

Performance Overview

1. Latest features:

-

Optional turnover alarms to enhance job site safety

2. Moving more materials with less fuel:

-

The 326GC can use biodiesel up to B20, which is in line with China's fourth non-road emission standard.

-

The advanced hydraulic system not only achieves an excellent balance between power and efficiency, but also gives you the control devices you need to meet your precise excavation requirements.

-

The valve prioritization sets the hydraulic pressure and flow rate according to your instructions, enabling fast low- and medium-load cycle times.

-

Match the excavator to the job using two power modes; It also automatically matches engine and hydraulic power with excavation conditions through smart mode.

-

The pump is controlled with positive flow to reduce lost energy and reduce fuel consumption. The pump flow can be automatically adjusted according to the valve priority.

-

Auxiliary hydraulic options give you the versatility you need to use a wide range of Cat tooling.

-

Advansys™The choice of shovel teeth improves penetration and shortens cycle time. A simple lug wrench, rather than a hydraulically powered impact hammer or special tool, can be used to quickly change the tips for improved safety and extended uptime. Provided only for heavy load shovels.

-

Standard ProductLink™You can accurately and automatically collect data from your assets (any type and any brand). Information such as location, hours, fuel usage, productivity, idle time, maintenance alerts, diagnostic codes, and machine health can be viewed online through web and mobile apps.

3. Lower maintenance costs:

-

Maintenance costs are expected to be reduced by up to 10% compared to the 326GC that meets the Nonroad Country III standard.

-

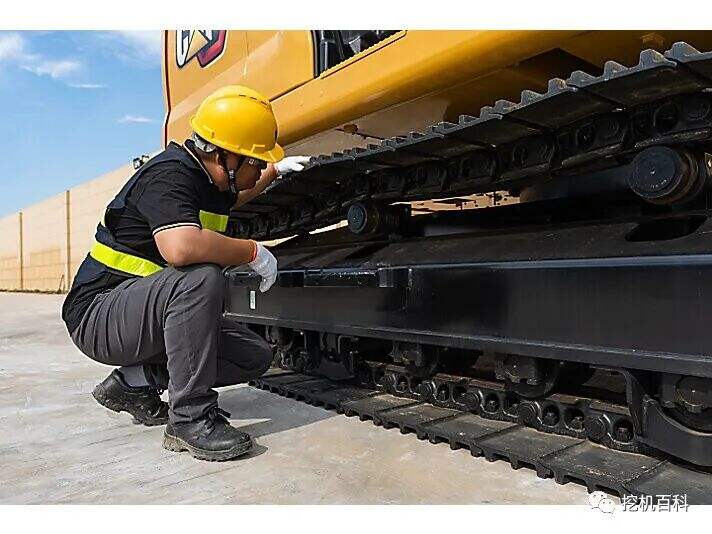

Perform all daily maintenance work on the ground.

-

Use new engine oil gauges near the ground to quickly and safely check engine oil levels; Using a second oil gauge at your fingertips, you can fill and check the engine oil at the top of the machine.

-

The filter life and maintenance cycle of the excavator can be tracked through a monitor in the driving room.

-

Replace all fuel filters every 1000 man-hours - 100% longer service life than the 326D2 fuel filter.

-

The new inlet filter with an integrated prefilter is expected to work continuously for 1,000 hours in some applications - a 100% increase in service life compared to previous filters.

-

The new hydraulic oil filter provides better filtration performance, and the reverse drain valve keeps the oil clean when the filter is replaced at a time of up to 3,000 working hours, giving a longer service life - 50% longer than previous filter designs.

-

Efficient cooling fans only operate when needed; You can set the spacing so that it can automatically reverse to keep the radiator core clean without interrupting your work.

-

The ground-mounted S · O · S sampling port simplifies maintenance and enables quick and easy extraction of oil samples for analysis.

4. Ensure reliability in any environment:

-

Can work at altitudes up to 3000 m (9,840 ft) without loss.

-

Perfect for temperature challenges and safeguard your normal work.The excavators can operate in high temperatures up to 52 ° C (125 ° F) and have cold start capabilities as low as -18 ° C (0 ° F).

-

The automatic preheating function heats the hydraulic oil more quickly in cold weather and helps extend the service life of the components.

-

Double fuel filtering prevents the engine from being affected by dirty diesel fuel.

-

Sealed between the track solder and the liner by grease can reduce driving noise and prevent debris from entering, thereby extending the service life of the chassis system.

-

The track steering guard helps the excavator's track to remain aligned while driving and working on a slope.

-

A sloping track rack prevents the accumulation of dirt and debris, helping to reduce the risk of track damage.

5. A comfortable, 24 / 7 drive room experience:

-

The driver's room is equipped with wide seats that can be flexibly adjusted to suit operators of all sizes.

-

The controlled devices at hand are all located in front of the operator, making it easy for the operator to control the excavator comfortably.

-

Standard automatic thermostats ensure a comfortable temperature throughout the operation.

-

Advanced adhesive seats reduce vibration in the driveway and make the driveway feel more comfortable.

-

Under and behind the seats and in the control room provide plenty of parking space in the driver's room for easy storage of operator equipment. Cup racks, bottle racks and hat hooks are also provided.

-

Supports connecting personal devices using USB ports and Bluetooth ® technology.

6. It's easy to do:

-

The engine can be started with a button or a unique operator ID function.

-

Use the operator ID to set the power mode and joystick preferences; Every time they work, the excavator remembers these preferences.

-

The Cat Single Handle option makes it easier to control the movement of the digging machine. With the press of a button, you can control driving and steering with one hand without having to control the steering lever with both hands or both feet on the pedal.

-

High resolution 203mm (8in) standard touch screen monitors or knob controls allow rapid navigation.

-

Don't know how a particular function works or how to maintain an excavator? The operator manual is accessible at any time with a touch of the finger on the touch screen monitor.

7. Every day can be safe operation, Ping An safe home:

-

All of the daily maintenance points are accessible from the ground - there is no need to climb to the top of an excavator.

-

Use the operator ID to ensure the safety of the digging machine. Use a PIN code on the monitor to enable button activation.

-

The standard ROPS driving room meets the requirements of ISO 12117-2: 2008.

-

Thanks to smaller cockpit columns, wide windows and a flat engine casing design, operators have an excellent view on both the inner side of the ditch, in every turning direction and behind. A rear-view camera is standard and a right-view mirror is available.

-

The right-side maintenance platform uses a new design to facilitate easy, safe and fast access to the upper maintenance platform. The maintenance platform staircase uses slippery perforated plates to prevent sliding.

-

When the standard hydraulic lock lever is in a lower position, it blocks all hydraulic functions and driving functions.

-

Once activated, the ground downtime switch will completely stop the delivery of fuel to the engine and shut down the machine.

-

Enhance job site safety. Add a turning alarm to alert the person concerned when rotating from the ditch to the pile and back again.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE