CAT 326 Classic inheritance, brand new upgrade

CAT 326 Classic inheritance, brand new upgrade

Medium-sized excavator

326

Summary

Provide superior performance using simple and easy-to-use technology.

The 326 excavator delivers superior performance with easy-to-use technology to increase operator efficiency . It also offers a new cab , longer maintenance intervals and a powertrain that reduces fuel consumption . The 326 is a very cost-effective excavator for medium to heavy duty applications .

-

Up to 20% Lower maintenance costs

-

Improve performance

Fuel consumption is reduced by up to 10%. Reverse torque increased by up to 12 percent and lift force increased by as much as 6 percent

-

Up to 45% more productive

Main technical specifications:

Power: 149.8 (158) kW

Machine weight: 26100kg

Bucket capacity: 1.54 m3

Performance parameters, are being worked out. Stay tuned!

Configuration of the whole machine

Standard: ● Option: ○

Arm and pole:

●5.9 m(19'4" ) Heavy load stretching arms

●2.95 m(9'8" ) Heavy load stretchers

○10.2 m(33'6" ) Very long stretching arms

○7.85 m(25'9" ) Extended stretcher pole

The chassis system and structure:

● Chain points on the basic frames

● 4600 (10141 lb) Counterweight

○600 mm(24" ) Double-clawed ground teeth track plate

○600 mm(24" ) Three-clawed ground teeth track plate

○790 mm(31" ) Three-clawed ground teeth track plate

○ 7400 kg (16310 lb) counterweight

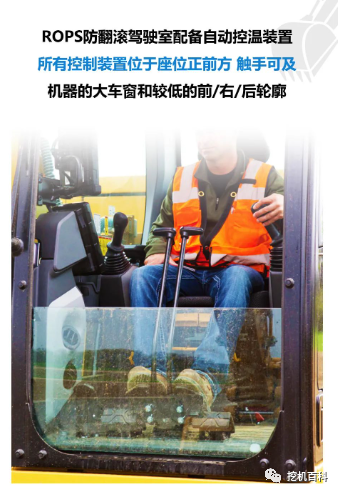

Driver's Room:

Roll Protection Structure (ROPS)

● High resolution 203mm (8in) LCD touch screen monitor

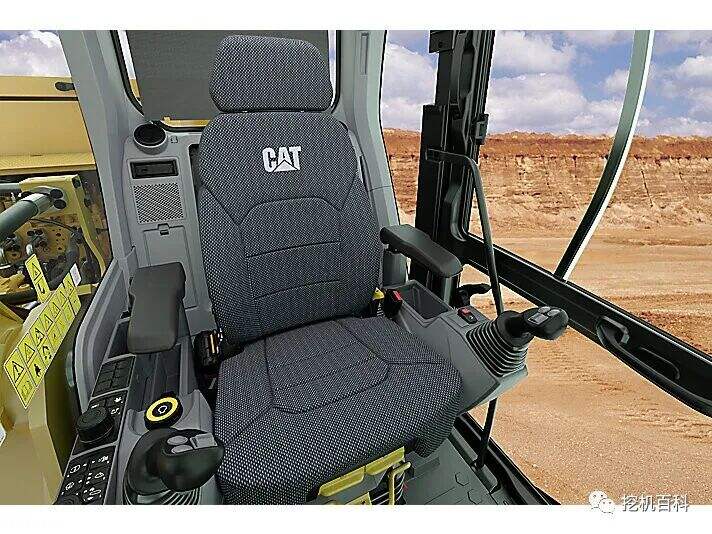

Mechanical suspension seats (only in the comfortable driver's room)

Heated air suspension seats (limited to luxury cabs)

○ High resolution 254mm (10in) LCD touch screen monitor

○ Cat Single Handle

Assist relays (limited to luxury cabs)

Electrical systems:

● Maintenance-free 1000CCA battery

● Programmable delay time LED work light

● LED chassis lights, left and right arm lights, driving room lights

Powertrain:

Cat 7.1 single turbocharged fuel and oil engine

Three optional power modes: Power, Smart and Fuel Efficient

Automatic engine idle shutdown

● 52 ° C (125 ° F) high temperature environment cooling capacity (with deductions)

● -18 ° C (0 ° F) cold start capability

Dual-core air filter with integrated prefilter

● Reverse electric cooling fan

Biodiesel with a maximum label of B20 can be used

○ -32 ° C (-25 ° F) cold start capability

Hydraulic system:

Electronic main control valve with tool control

Automatic hydraulic oil preheating

● Running at two speeds

● Arm and buttrest subduction valves

Automatic mining enhancements

Serial electric main pump

● Filter type main hydraulic filter

Safety and protective devices:

• Ground engine stop switch

• Right handrails and handles

• Signal / alarm horn

○ Cat Detect - Personnel Detection

○ BACK VIEW camera

○ Right-side camera

360 ° View

○ Turnaround alarm

CAT Technology:

Remote refresh

Remote troubleshooting

● Cat with auxiliary functions

●Cat Payload

2D electronic fence

Hydraulically powered impact hammer

○ CatGrade connections

Cat Grade with advanced 2D systems

Cat Grade with 3D system single GNSS technology

Cat Grade with 3D System Dual GNSS Technology

Repair and maintenance:

● Planned analysis of oil sample (S · O · S) sampler

• Ground and platform engine oil gauges

Electric refueling pump with automatic disconnect function

Performance Overview

1. Latest features:

-

Optional Cat Detect - Personnel Detection features help operators avoid personnel at the job site with visual and auditory alerts.

-

The optional single-antenna Global Navigation Satellite System (GNSS) provides visual and acoustic guidance on slope.

-

Optional auxiliary relays open and close CB radios, Denso lights and other fixtures without loosening the control handle.

-

Turning alarms can be optional to enhance job site safety.

2. Performance and productivity:

-

Control is better than 326 D2.

-

When smart mode is used, fuel consumption can be reduced by 5% without reducing productivity.

-

The revolving torque increased by 12 per cent, making it easier to work on slopes.

-

Standard Cat technology reduces operator fatigue and saves operating costs (including fuel consumption and routine maintenance), increasing operational efficiency by up to 45 percent.

-

The C7.1 engine can use up to B20 biodiesel, in line with China's fourth non-road emission standards.

-

The advanced hydraulic system not only achieves an excellent balance between power and efficiency, but also gives you the control devices you need to meet your precise excavation requirements.

-

Match the excavator to the job using two power modes; The Smart mode automatically matches the engine and hydraulic power to the excavation conditions.

-

Advansys™The choice of shovel teeth improves penetration and shortens cycle time. A simple lug wrench, rather than a hydraulically powered impact hammer or special tool, can be used to quickly change the tips for improved safety and extended uptime.

-

Auxiliary hydraulic options give you the versatility you need to use a wide range of Cat tooling.

-

Perfect for temperature challenges and safeguard your normal work.The excavator can operate at high temperatures up to 52 ° C (125 ° F) (with deductions) and has cold start capabilities as low as -18 ° C (0 ° F).Optional -32 ° C (-25 ° F) starter kits are available.

3. Excellent technology:

-

With the standard CatGrade with a 2D system, including "Display Only" and laser capabilities, productivity increases by up to 45% over conventional slope trimming machines.

-

Markup aids: The slope is easily and easily maintained through the single-bar excavation function.

-

Set the desired shovel angle, which can be automatically maintained by the shovel assistance feature in slope repair, flattening, fine smoothing, and trenching applications.

-

With the help of an auxiliary cranes, the track can be kept grounded during lift and hard material excavation operations.

-

With revolving assist, in truck loading and tunneling applications, the excavator's revolving is automatically stopped at a set point defined by the operator, which will help you reduce workload and reduce fuel consumption.

-

Cat Payload helps to achieve precise load targets and improve operational efficiency. Use a combination of a shovel and a thumb cutter or a grab and cutter loader to dig up a crate of material and get an estimated weight in real time without even swirling.

-

Combine Payload with VisionLink ® to remotely manage your production goals.This application can now be downloaded to a USB stick.

-

Upgrade to optional CatGrade with an advanced 2D system: Easily create and edit slope designs on a second high-resolution 254mm (10in) touch screen monitor.

-

Is it necessary to use a 3D system to improve excavation? Caterpillar's new single-antenna Global Navigation Satellite System (GNSS) provides visual and audio guidance on slope, making this easy. In addition, you can create and edit designs on a touch screen monitor while you are working. If your application requires a dual antenna system, it can be easily upgraded.

-

Upgrade to our dual antenna GNSS to maximize the efficiency of the leveling operation. This system allows you to create and edit designs on a touch screen monitor while working, or to send planned designs to the excavator, making the job easier. In addition, you can enjoy even more benefits, including avoidance zones, mapping of digging and filling areas, route guidance, augmented reality, and advanced location features.

-

You can use the remote troubleshooting feature to contact agent service professionals at any time to help resolve your issues and get back to work quickly.

-

The remote refresh function runs as planned, ensuring that the machine software remains up to date, thus optimizing performance.

-

All CatGrade systems are compatible with signal transmitters and base stations from Trimble, Topcon and Leica. Have you purchased slope infrastructure? You can install slope systems from Trimble, Topcon and Leica to your machine.

4. Working in comfort:

-

The comfortable driver's room is equipped with mechanical levitation seats. The luxurious seats are heated and air-adjusted.

-

The advanced rigid base reduces vibration in the cab by up to 50 per cent compared to previous excavator models.

-

The controlled devices at hand are all located in front of the operator, making it easy for the operator to control the excavator comfortably.

-

Under and behind the seats and in the control room provide plenty of parking space in the driver's room for easy storage of operator equipment. Cup racks, bottle racks and hat hooks are also provided.

-

Connect personal devices and make hands-free calls easily with a standard wireless USB port and Bluetooth ® technology.

5. It's easy to do:

-

The engine can be started with a button or a unique operator ID function.

-

Use the operator ID to set the power mode and joystick preferences; Every time they work, the excavator remembers these preferences.

-

The Cat Single Handle option makes it easier to control the movement of the digging machine. With the press of a button, you can control driving and steering with one hand without having to control the steering lever with both hands or both feet on the pedal.

-

High resolution 203mm (8in) standard touch screen monitors or knob controls allow rapid navigation.

-

Don't know how a particular function works or how to maintain an excavator? The operator manual is accessible at any time with a touch of the finger on the touch screen monitor.

-

The Cat PL161 Tooling Positioner is a Bluetooth device that helps you quickly and easily find tooling and other equipment. The Cat app on your phone will automatically locate the device.

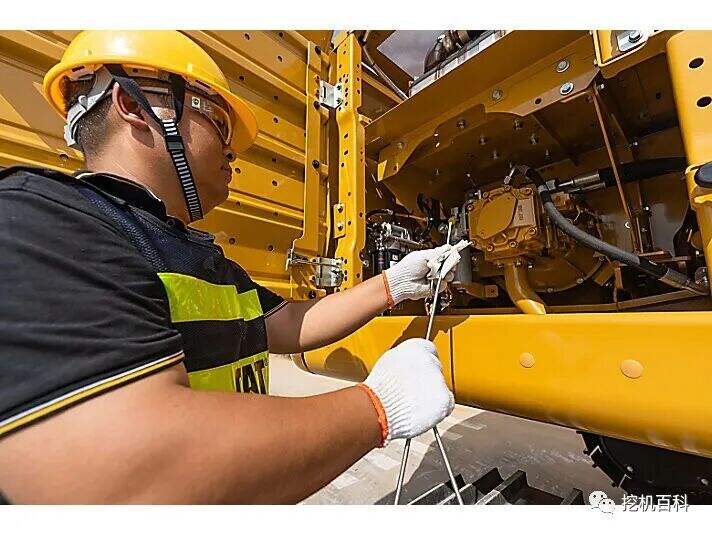

6. Lower maintenance costs:

-

Maintenance costs are expected to be reduced by up to 20% compared to the 326D2 (savings based on 12,000 machine hours).

-

Perform all daily maintenance work on the ground.

-

Use new engine oil gauges near the ground to quickly and safely check engine oil levels; Using a second oil gauge at your fingertips, you can fill and check the engine oil at the top of the machine.

-

The filter life and maintenance cycle of the excavator can be tracked through a monitor in the driving room.

-

Using Cat OEM oil and filters and performing typical S.O.S. monitoring can extend current service intervals to 1,000 hours, twice as long as before, allowing you to get longer uptime to get more work done.

-

The new inlet filter with a prefilter is expected to last 1,000 hours - a 100% increase in service life compared to previous filters.

-

The new hydraulic oil filter provides better filtration performance, and the reverse drain valve keeps the oil clean when the filter is replaced at a time of up to 3,000 working hours, giving a longer service life - 50% longer than previous filter designs.

-

Efficient cooling fans only operate when needed; You can set the spacing so that it can automatically reverse to keep the radiator core clean without interrupting your work.

-

The ground-mounted S · O · S sampling port simplifies maintenance and enables quick and easy extraction of oil samples for analysis.

7. Built-in security features:

-

All of the daily maintenance points are accessible from the ground - there is no need to climb to the top of an excavator.

-

Cat Detect - People detection helps protect the most valuable asset in any job site: people. The system uses a smart camera with a depth sensor that provides the operator with visual and auditory alerts to take immediate action if a person gets too close to the excavator.

-

The standard ROPS driving room meets the requirements of ISO 12117-2: 2008.

-

Thanks to smaller cockpit columns, wide windows and a flat engine casing design, operators have an excellent view on both the inner side of the ditch, in every turning direction and behind.

-

The 2D electronic fence prevents the excavator from moving beyond the set point defined by the operator; The system uses a combination of thumb bucket and bucket and hydraulically powered impact hammer, grab bucket and bucket tooling.

-

When the standard hydraulic lock lever is in a lower position, it blocks all hydraulic functions and driving functions.

-

Once activated, the ground downtime switch will completely stop the delivery of fuel to the engine and shut down the machine.

-

Choose a rear-view camera and a right-view camera.Upon upgrading to 360 ° view, you will be able to easily view objects and people around the excavator in a single view.

-

The right-side maintenance platform is designed to facilitate easy, safe and fast access to the upper maintenance platform; The maintenance platform staircase uses slippery perforated plates to prevent sliding.

-

Optional boom and arm drop check valves prevent reverse flow and hold the front link firmly in place in the event of accidental loss of power in the hydraulic system.

-

Brightly coloured seat belts help easily identify whether the security device is being used correctly.

-

Enhance job site safety. Add a turning alarm to alert the person concerned when rotating from the ditch to the pile and back again.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE