CAT 316GC Classic inheritance, brand new upgrade

CAT 316GC Classic inheritance, brand new upgrade

Small excavator

316 GC

Summary

If you need high reliability, durability, productivity and low cost, Cat ® 316GC is the right choice.This excavator is carefully designed and built with unparalleled support from a team of professionals to help you on your path to success.

-

Up to 15% productivity improvement

The engine is more powerful and has greater excavator power, giving you the power you need to increase your productivity.

-

Up to 20% Lower maintenance costs

Maintenance intervals are longer and more synchronised, so you can do more work at a lower cost.

-

Built for everyday tasks

The 316GC is affordable, easy to operate, and delivers the reliability and durability expected of Cat ® products.

Main technical specifications:

Power: 77.3kW

Machine weight: 14300 kg

Bucket capacity: 0.65 m3

Configuration parameters

Standard: ● Option: ○

Maximum turning torque 43 kN · m

Bucket digging force - ISO 109 kN

Arm Digging Force - ISO 75 kN

Rotary speed 11.5 r / min

Powertrain:

Engine Model: Cat C3.6

Hydraulic system:

Main System - Maximum flow rate: 268 L / min

Maximum pressure - equipment: 35000 kPa

Maximum pressure - driving: 35000 kPa

Maximum pressure - turning: 26000 kPa

Boom cylinder - stroke 1015 mm

Boom Cylinder - Bore 105 mm

Rod Cylinder - Stroke 1197 mm

Rod Cylinder - Bore 120 mm

Bucket Cylinder - Stroke 939 mm

Bucket Cylinder - Bore 100 mm

The arms and arms are:

● 4.65m boom

● 2.5m bucket rod

● 0.65 m3 GD bucket

Oil and water injection:

Fuel tank capacity 237 L

Cold Pepper System 11 L

Engine oil 11 L

Final Drive - 3 L each

Hydraulic pressure system - includes tank 145 L

Hydraulic Oil Tank 77 L

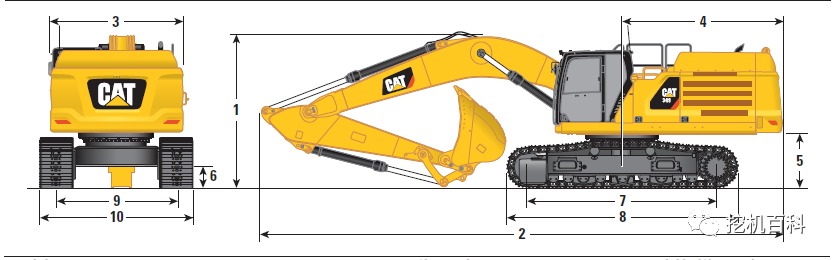

Form factor:

Loading height - top of driving room 2780 mm

Handrail height 2830 mm

Shipping length 7770 mm

Tail radius of gyration 2290 mm

Counterweight clearance 900 mm

Ground clearance 425 mm

Track length 3750 mm

Center spacing of the supporting wheels 3040 mm

Track gauge 1990 mm

Transport width 2490 mm

Roller center spacing 3040 mm

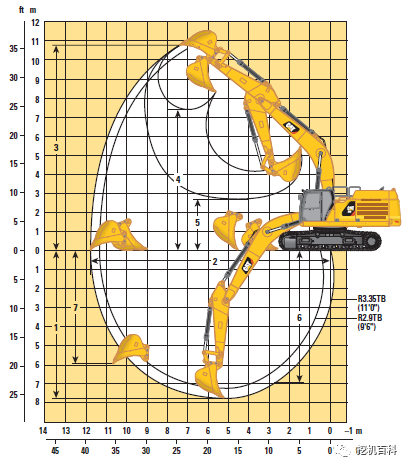

Operational scope:

Maximum excavation depth 5530 mm

Maximum ground extension 8180 mm

Maximum excavation height 8500 mm

Maximum loading height 6110 mm

Minimum loading height 2020 mm

Maximum excavation depth of 2440 mm flat bottom 5330 mm

Maximum vertical wall excavation depth 4860 mm

Functional configuration

Standard: ● Option: ○

Driver's Room:

-

Noise-absorbing cab with a sticky plinth

-

High resolution 203 mm (8 " LCD touch screen monitor

-

Mechanically adjusted seat with headrest

-

Automatic two-level air conditioning

-

Pressed starting engine control device without key

-

Adjustable console mounted on the floor

-

One-click manipulation of the handle

-

AM / FM Recorder with USB and Auxiliary Ports

-

24V DC socket

-

Cup holder and storage room

-

70 / 30 steel windshield

-

Upper radial washer with a washer

-

Steel hatch openable

-

top light

-

Cleanable floor mats

CAT Technology:

-

Cat Product Link

Electrical systems:

-

Maintenance-free 750CCA battery (2 units)

-

Electrical circuit switches

-

LED Left Arm and Chassis Light

○ LED Right Arm Light

○ LED Cab light

Engine:

-

Three optional power modes: Power, Smart and Fuel Efficient

-

52 ° C (125 ° F) High temperature ambient cooling capacity

-

18 ° C (0 ° F) cold start capability

-

Biodiesel up to B20 can be used

-

Electric fuel injection pump

-

Level 2 Fuel Filtration System

-

Sealed double filter air filter with prefilter

○ -25 ° C (-13 ° F) cold start capability

Hydraulic system:

-

Electronic main control valve, reserved hydraulically powered impact hammer mounting position

-

Electronically Controlled Pump

-

The arms and pole regeneration circuit

-

Automatic hydraulic oil preheating

-

Automatic two-speed travel

-

High Performance Hydraulic Oil Recovery Filter

Hydraulically powered impact hammer line

○ Hydraulically powered impact hammer pedal kit

Safety and protective devices:

-

Anti-skateboard with buckles

-

Handrails and handles

-

Lockable external toolbox / storage box

-

Rearview mirror kit

-

Signal / alarm horn

-

Hydraulic Locking Grip

○ BACK VIEW camera

Repair and maintenance:

-

The filter is placed centrally

-

radiator grille

-

S · O · S Sampling Port

The chassis system and structure:

-

500 mm(20" ) Three-clawed ground teeth track plate

-

Central track leading guard

-

Lubricating oil to lubricate track joints

-

Bottom Protector

-

Running motor shield

-

3.2 mt (7055 lb) Counterweight

-

Chain points

○ 600 mm(24" ) Three-clawed ground teeth track plate

Performance Overview

1. Performance reliable and durable:

-

The 316 GC has been redesigned to increase productivity by 15% compared to the previous 313 D2 GC model.

-

The C3.6 engine provides more powerful power, more fuel efficient, and complies with China's non-road fourth emission standard.

-

Excavation power was increased, and the revolving drive was redesigned to increase revolving torque and smoothness, thereby increasing productivity.

-

The new main hydraulic pump uses electronic control to achieve greater efficiency and provides nearly two times the flow rate compared to previous models, increasing control capacity and productivity.

-

The chassis system and track design can better meet high production demands and provide excellent stability.

-

The upper rack has been enhanced to increase the durability of the 316 GC.

-

Hydraulically powered impact hammer / tool valves increase versatility, while a wide range of bucket and tool options allow you to accomplish more tasks.

-

The shovel serial nuts were strengthened to provide greater excavation power.

-

The arm is reinforced with specially tailored steel bars, making the 316GC reliable enough to handle any demanding job application.

2. Reduce ownership and operating costs:

-

Provides three modes of operation to select power according to specific jobs: intelligent, which automatically adjusts power accordingly to demand; Save fuel and can reduce fuel consumption; Strong enough to achieve the highest productivity.

-

Designed to simplify maintenance and reduce maintenance costs, the 316GC can reduce costs by up to 20%.

-

The service life of the hydraulic and air filters was extended, and the precursor filters and boiler exhaust filters were eliminated.

-

Most day-to-day maintenance can be done on the ground, reducing the time spent on routine tasks.

-

The reverse drive operates on a hydraulic system and does not require inspection or refueling of other oil systems.

-

The amount of hydraulic fluid and engine oil supplementation was reduced, without any change in performance or service life.

-

When hydraulics are low, the AEC (Automatic Engine Control) system reduces the speed, which reduces your fuel costs.

-

Cat Product Link™The system is standard, so you can remotely monitor fuel consumption, machine health, location, and hours as needed via VisionLink ®.

3. It's easy to do:

-

The button starter engine is easy to operate.

-

With a one-click control handle with adjustable control handle response and gain, any operator can control it with ease.

-

A simplified control menu on a high resolution 203mm (8in) touch screen monitor enables fast navigation.

4. Working in comfort:

-

The wide seat (larger than previous models) is suitable for operators of all sizes.

-

Standard automatic thermostats ensure a comfortable temperature throughout the operation.

-

Convenient configurations such as a cassette player, a headphone port, and a USB port for connecting and charging devices are available.

-

There is a cupholder and storage space in front of the control device for large-capacity water cups and a widescreen mobile phone; The storage space behind the seat holds a safety helmet, a large lunch box and other items.

5. Easy to maintain:

-

Almost all major mechanical components can be checked on the ground or on a maintenance platform.

-

The radiator filter can be easily removed, is easy to clean, and can eliminate small debris, such as grass, that are difficult to remove on the radiator.

-

Easily accessible to the engine room from the maintenance platform; The oil lid and level meter can be easily retrieved and released, and the automatic tightening ensures that you do not need to adjust the conveyor belt.

-

Cat technology helps you monitor your machines, and the Caterpillar service network helps you maximize uptime.

6. Higher security:

-

Most daily maintenance points are accessible from the ground.

-

Emergency engines and electrical switches can also come into contact on the ground.

-

Handrails comply with ISO 2867: 2011; Steps and platforms use anti-skateboards with buckles to prevent slips and tripping.

-

In an emergency, the operator can climb out of the machine through a back window or steel skylight.

-

The new cab uses a larger window and smaller cab pillar design to provide excellent views on the inner side of the ditch and in all directions.

-

Bright external LED lights and an optional rear-view camera ensure that you are well aware of your surroundings at work.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE