CAT M315GC Classic inheritance, brand new upgrade

CAT M315GC Classic inheritance, brand new upgrade

Small wheel excavator

M315GC

Summary

It improves performance and reduces the cost of daily use.

The Cat M315 GC Wheel Digger's more comfortable driving rooms and simple controls increase your efficiency and productivity, helping you get more done each day. Lower maintenance costs and lower fuel consumption, saving you money.

-

Built for everyday tasks

The M315GC is affordable, easy to operate, and offers the reliability and durability expected of Cat ® products.

-

Performance improvement

The M315 GC increases productivity by up to 10%. Enhanced excavatoring power helps you get more work done every day.

-

Increasing earnings

Lower maintenance costs and gas consumption, increase operating time and maintain low costs.

-

Up to 10% CO2 emissions are even lower

The M315 GC emits up to 10% less CO2 than the previous M315D2.

Main technical specifications:

Power: 110 kW

Machine weight: 13990 kg

Bucket capacity: 0.65 m3

Configuration parameters

Standard: ● Option: ○

Power:

Maximum turning torque 34 kN · m

Gravity 71 kN

Dipper digging force - ISO 69 kN

Arm Digging Force - ISO 83 kN

Maximum ability to climb a hill 60%

Speed:

Rotary speed 11.5 r / min

Forward / Reverse - 1st Gear 9 km / h

Forward / Reverse - 2nd gear 37 km / h

Crawl speed - 1st gear 6 km / h

Crawl speed - 2nd gear 15 km / h

Noise performance:

Operator noise - 2000 / 14 / EC 71 dB (A)

Observer noise - 2000 / 14 / EC 102 dB (A)

Reference criteria:

Actuator: ISO 3450: 201

Vibration Class - Maximum Hand / Arm Vibration - ISO 5349: 2001:

<2.5 m/s²(<8.2)

Vibration Class - Maximum Vehicle Body - ISO / TR 25398: 2006:

<0.5 m/s²(<1.6)

Vibration classes - Seat transmission factors - ISO 7096: 2000 - Spectral category EM6: < 0.7

Driving Room / FOGS:

ISO 10262:1998 及 SAE J1356:2008

Driving Room / Noise Level: Compliance with the applicable standards listed in the Noise Performance section.

Powertrain:

Engine Model: Cat C4.4

Emissions standards: Country IV

Maximum altitude: 3000 mm

Hydraulic system:

Maximum pressure:

Tool circuit - normal 35000 kPa

Machine Loop - Heavy Lift 35000 kPa

Machine circuit - running circuit 35000 kPa

Auxiliary circuit - high voltage 35000 kPa

Auxiliary circuit - rotary mechanism 25900 kPa

Main system traffic:

Maximum flow rate - Tool 245 L / min

Maximum flow rate - 180 L / min in travel circuit

Auxiliary circuit - high voltage 100 L / min

Auxiliary circuit - rotary mechanism 122 L / min

Fuel tank:

Boom Cylinder (Integral) - Bore 105 mm

Boom Cylinder (Integral) - Stroke 932 mm

Rod Cylinder - Bore 95 mm

Rod Cylinder - Stroke 939 mm

Bucket Cylinder - Bore 115 mm

Bucket cylinder - stroke 1147 mm

Working appliance:

4.4m integral boom

● 2.2m rod

●312 mm 连杆

● 0.65 m3 Bucket - General Load Type

Weight: 490kg

Tooth tip radius: 1225 mm

Width: 1050 mm

○ 0.2 m3 Bucket - Narrow Bucket

Weight: 291 kg

Width: 450 mm

○ 100 ~ 115mm hydraulically powered impact hammer

○ CVP75 Vibrating Plate Rammer

The chassis system and structure:

Standard tyres 10.00-20 (double inflatable)

Minimum turning radius - 6750 mm outside tire

Minimum turning radius - bottom end of integral boom 7950 mm

Angle of the swing shaft ± 9 °

Maximum swing angle 35 °

Ground clearance 360 mm

Ground shovels:

Types of shovels

Width 2490 mm

Blade turning height 583 mm

Total blade height 610 mm

Maximum depth of 610 mm that can be lowered from the ground

Maximum height from the ground 475 mm

Main component weight:

Boom 2600 kg

Bulk rods (including fuel tanks, shovel joints, solders and standard hydraulic piping)

633 kg

Weight 2600kg

chassis system (including axles, standard tires and ladder)

4299 kg

Bucket 490 kg

Quick coupler 187 kg

Oil and water injection:

Fuel tank capacity 250 L

23 L of cold water

Engine oil 15 L

Hydraulic Oil Tank 98 L

Hydraulic pressure system - includes tank 230 L

Rear Axle - Housing (Differential) 11 L

Front Steering Shaft - Differential 9 L

Final Drive 2 L

Power Shift Gearbox 3 L

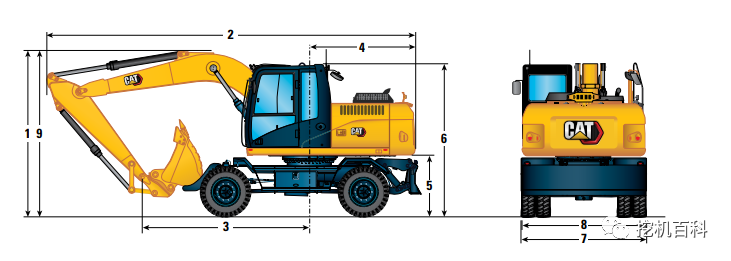

Form factor:

1 Shipping height 3245 mm

2 Shipping Length 7920mm

3 Support Points 2414mm

4 Rear gyration radius 2190 mm

5 Counterweight clearance 1264 mm

6 Driving Room Height:

Without falling object protection 3131 mm

With falling object protection 3245 mm

7 Machine width (including blade) with 10.00-20 tires 2540 mm

8 Upper rack width 2490 mm

9 Height in driving position 3675 mm

Chassis system size (10.00-20 double inflatable tires):

10 Total length of chassis 4846 mm

11 wheelbase 2800 mm

12 Slewing bearing center to rear axle 1700 mm

13 Slewing bearing center to front axle 1100 mm

14 rear axle to parallel blade (end) 1168 mm

15 Blade width 2490 mm

Maximum blade depth 108 mm below ground

16 Case height (door) 2535 mm

17 blade clearance (parallel) 474 mm

18 axle clearance 360 mm

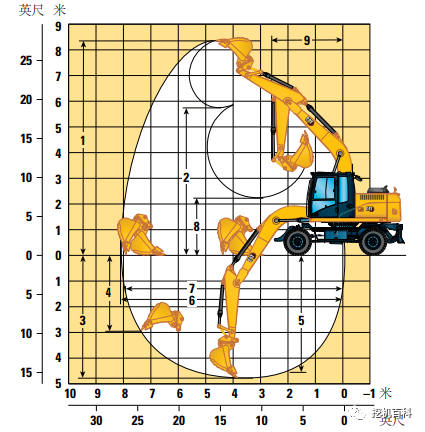

Operational scope:

Fast connector by scratch No Yes Yes

1 Maximum excavation height 8254 mm 8392 mm

2 Maximum loading height 5892 mm 5722 mm

3 Maximum excavation depth 4624 mm 4795 mm

4 Maximum vertical wall excavation depth 3777 mm 2962 mm

5 2440 mm Maximum excavation depth with flat bottom 4361 mm 4556 mm

6 Maximum extension distance 7941 mm 8112 mm

7 Maximum extension distance - ground 7739 mm 7914 mm

8 Minimum loading height 2394 mm 2223 mm

9 Minimum front radius of gyration 2600 mm 2600 mm

Functional setup

Standard: ● Option: ○

Working appliance:

-

4.4 m(14'5" ) The overall arm

-

2.2 m(7'3" ) Fighting Stick

○ Shovel hooks, 312 Series no cranes

Electrical systems:

-

LED lights on the boom and driving room

-

Forward and backside traffic lights and indicator lights

-

Battery maintenance free

-

Centralized Electrical Shutdown Switch

○ LED light on the chassis (right)

Electrical refueling pump

Engine:

-

Cat ®C4.4 Single turbocharged diesel engine

-

Power Mode Selector

-

One-touch low idle speed function with automatic engine speed control

-

Automatic idle shutdown

-

It can operate at altitudes up to 3000 m (9840 ft) without engine power loss.

-

52 ° C (125 ° F) high temperature ambient cooling capacity

-

Dual-core air filter with integrated prefilter

-

Electric fuel injection pump

-

Biodiesel up to B20 can be used

○ -18 ° C (-0 ° F) cold start capability

○ -25 ° C (-13 ° F) cold start capability

Hydraulic system:

-

Arm, pole, and shovel subsidence valves

-

Electronic main control valve

-

Filter type main hydraulic filter

-

Automatic reverse brake

-

Adjustable hydraulic propulsion speed

○ 1 slider to manipulate the handle

○ Three-button manipulation grip

○ Advanced tool control device (one-way / two-way high-pressure flow, reduced sinking)

○ Quick Connector Circuit for Cat Pin Gripper

Safety and protective devices:

-

BACK VIEW camera

-

Signal / alarm horn

-

Horizontal steering lever (lock) for all control devices

-

The auxiliary engine stop switch in the cab can be reached from the ground

-

Maintenance of anti-skateboards and buckles on the platform

○ Right-side camera

○ Traffic alarm

○ The rotating sign lights in the cab

○ Cat Asset Tracker

Repair and maintenance:

-

Planned analysis of oil sample (S. O. SSM) sampler

CAT technology :

-

Cat Product Link

The chassis system and structure:

-

all-wheel drive

-

Automatic braking / axle lock

-

Climbing speed

-

Electronic steering and driving lock

-

Heavy axles, advanced disc braking systems and drive motors, tunable power

-

Wriggling front axles, locked, with remote lubrication points

-

10.00-20 16 PR, Double Tires

-

Staircase in the chassis system with a left toolbox

-

Two-piece drive shaft

-

Dual-speed static hydraulic transmission

-

A rear shovel chassis system with shovel support

-

Front and rear steel fenders

-

2600 kg (5730 lb) counterweight

○ Transmission shaft protection

○ Heat shield

Performance Overview

1. Fuel saving performance matching the type of work:

-

Reduce fuel consumption by up to 10% compared to the M315D2, helping you maintain continuous efficient operation on the job site.

-

The engine is faster, enabling a high level of driving and operational performance.

-

Reduced fuel consumption and less noise can help improve many different types of work environments.

-

The Cat C4.4 engine complies with China's Non-Road Country IV emission standards.

-

ProductLink is compliant and can be used to monitor machine condition, location and safety.

-

The advanced hydraulic system not only achieves an excellent balance between power and efficiency, but also provides the control devices needed to meet precise excavation requirements.

-

Auxiliary hydraulic options give you the versatility you need to use a wide range of Cat tooling.

-

Perfect for temperature challenges and safeguard your normal work.The wheel excavator can operate in standard high temperatures up to 52 ° C (125 ° F).

2. Lower maintenance costs:

-

Maintenance costs are expected to be reduced by up to 15% compared to the M315D2.

-

The daily maintenance point can be repaired from the ground to achieve rapid inspection and repair of the machine.

-

The new hydraulic oil filter provides better filtration performance, and the reverse drain valve keeps the oil clean when the filter is replaced, and the interval between replacements is up to 2,000 working hours, giving a longer service life.

-

The replacement interval was longer and the lubrication points were classified, which reduced downtime and helped to get more work done.

-

The S · O · SSM sampling port is located on the ground, simplifying maintenance work and enabling quick and easy extraction of oil samples for analysis.

-

Building on a long tradition of producing high-performance, highly reliable wheeled digging machines, our machine components are designed and manufactured to meet Caterpillar's quality standards.

3. Working comfortably in a brand new cab:

-

The new and spacious driver's room improves operator productivity.

-

Upgraded seats improve operator comfort and reduce fatigue.

-

Access to the driver's room is made easier with a flip-up left console and a floor-to-ceiling design.

-

The ease of placing meal boxes, documents and mobile phones helps the operator to maintain a sense of comfort while at work.

-

The Bluetooth radio enables a seamless connection with the phone, allowing you to listen to music and radio as well as make hands-free calls.

-

The touch screen monitor can easily adjust to your ideal temperature.

4. It's easy to do:

-

Use the one-click starter button to easily start the machine.

-

Use easy-to-reach and intuitive operating mechanisms to operate this wheeled excavator comfortably.

-

High resolution 203mm (8in) touch screen monitors for fast navigation.

-

The two-way driving pedal is convenient and practical, helping to achieve high production efficiency.

5. Security features:

-

Day-to-day repair and maintenance sites are easy to maintain and highly secure.

-

Standard LED lights provide you with a clearer view of the job site.

-

With smaller cockpit columns, larger windows and a flat engine casing design, operators have a better view, both on the inner side of the ditch, in every turning direction and behind. Standard rear-view camera and side-view camera.

-

The maintenance platform is designed to facilitate easy, safe and fast access to the upper maintenance platform; The maintenance platform staircase uses slippery perforated plates to prevent sliding.

-

The lubrication points are grouped so that preventive lubrication can be done easily and quickly.

-

Use your PIN code on the monitor to enable button activation.

-

The reverse lock prevents the front joint from moving while you are driving.

-

Once activated, the ground downtime switch will completely stop the delivery of fuel to the engine and shut down the machine.

-

Special junctions ensure the safety of vehicular transport.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE