VOLVO EW60 Classic inheritance, brand new upgrade

VOLVO EW60 Classic inheritance, brand new upgrade

Small wheel excavator

EW60 CN4

Configuration parameters

Standard: ● Option: ○ Reference value: * To be refined: /

1. Performance parameters:

|

force |

Traction force |

29 |

kN·m |

|

Bucket Digging Force - ISO |

43.4 |

kN |

|

|

Bucket Rod Digging Force - ISO |

27.6 |

kN |

|

|

Rotation torque |

11.6 |

kN·m |

|

|

speed |

Reverse speed |

9.2 |

r/min |

|

Walking speed (road / field) |

30/10 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

/ |

° |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Volvo D2.6H |

|

|

Rated power - total |

47.3/2400 |

kW/rpm |

|

Maximum torque |

222/1500 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

EGR |

3. Hydraulic system:

|

The technical route |

/ |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

|

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*60 |

L |

|

The overflow valve settings: |

||

|

Working Circuit |

23 |

MPa |

|

Turning the oil road |

19 |

MPa |

|

Walking the oil road |

23 |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

2900 |

mm |

|

Fighting clubs |

1600 |

mm |

|

The shovel fighter looks |

0.176 |

m³ |

5. The chassis system:

|

Weight of weight |

/ |

kg |

|

Number of tyres |

2-2 |

|

|

Tire Specifications |

12-16.5 12PR |

|

|

tread |

1595 |

mm |

|

wheelbase |

2100 |

mm |

6. Amount of oil and water added:

|

Fuel tank |

105 |

L |

|

Hydraulic system |

120 |

L |

|

Hydraulic fuel tank |

76 |

L |

|

Engine oil |

11 |

L |

|

Antifreeze Solution |

10 |

L |

|

Reverse gear oil |

/ |

L |

|

gearbox |

1.7 |

L |

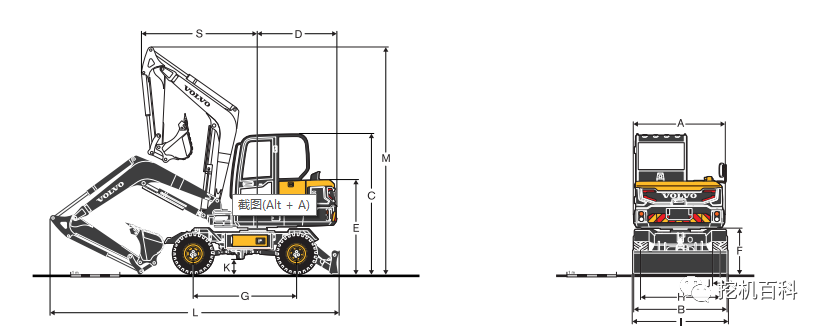

7. Form factor:

|

A |

Total upper structure width |

1845 |

mm |

|

B |

Total width |

1930 |

mm |

|

C |

Total height of the driver's room |

2855 |

mm |

|

D |

Tail pivot radius |

1650 |

mm |

|

E |

Total height of engine cover |

1901 |

mm |

|

F |

Gap between weight and ground |

960 |

mm |

|

G |

wheelbase |

2100 |

mm |

|

H |

tread |

1595 |

mm |

|

I |

The width of the earthen board |

1930 |

mm |

|

J |

Tire width |

305 |

mm |

|

K |

Minimum distance from the ground |

295 |

mm |

|

L |

Total length |

5869 |

mm |

|

M |

Total arm height |

4599 |

mm |

|

S |

Anterior rotation radius |

2352 |

mm |

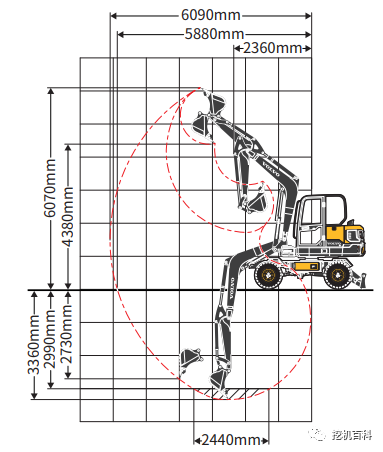

8. Operational scope:

1. Easy to operate

-

Increased storage space improves operator comfort and convenience.

-

The Volvo driver's room is equipped with a mobile phone tray, two power outlets, a cup seat and three other large storage areas for a more convenient working environment.

2. Operator visibility

-

The slimmer columns, a wider area of glass and a larger rain scrape enhance the overall view.

-

The rear-view camera provides the operator with a better view with a 7-inch color LCD display screen for smooth and safe handling. This ensures that there are no blind spots in even the narrowest port operation section.

3. Work comfortably

-

The seats are comfortable and adjustable, enabling the operator to devote himself to his work throughout the day and reduce fatigue at the end of the job.

-

The cabin air conditioning has been improved by about 10 per cent in efficiency and the temperature will be kept at the set level in automatic mode. Six adjustable vents improve air flow in the driver's room.

4. Easy to control

-

Machines can be easily controlled and can do more in less time.

-

The keypad places all controller groups on the right, and the 7-inch color LCD screen displays all machine information for easy access to functions through menus.

-

The operator can directly access the preset functions through the hot key, making it easier to operate.

-

The new scale holder has been improved to make it easier to grasp, perfectly suited to thumb operation and easy to control.

1. Proven engine technology

-

Since 2014, Volvo engines that meet the Tier 4 standard have been extensively verified worldwide.

-

Thanks to nearly 10 years of technical testing, validation and improvement, this engine has increased power by about 11% with exceptional levels of quality, reliability and efficiency.

2. Smooth operation

-

With smooth compounding operations, the machine can perform various actions accurately and precisely.

-

The controller is responsive and the machine works exactly as the operator intends, reducing fatigue and operating smoothly.

3. Wide range of uses

-

It is suitable for all operational sites, whether in a narrow space or in a major construction area.

-

The compact design of this machine, equipped with extended arms, optional fixed and offset arms, expanded earth shovels, auxiliary hydraulic systems and thumb clamps, is suitable for a variety of jobs and applications.

4 . Wheel Drive Performance

-

With a top speed of 30 km / h, the four-wheel drive allows for greater travel and off-road mobility.

-

The ability to easily drive the machine between different locations and easily access difficult-to-reach worksites saves time and keeps the machine in optimum condition.

1. Low fuel consumption

-

With the new Volvo engine and an improved hydraulic pressure system, greater fuel efficiency is achieved, reducing fuel consumption by around 4% through the use of ECO mode.

-

Standard automatic idling helps further reduce fuel consumption and increase profits.

2. Automatic engine shutdown

-

Volvo's unique engine automatically shuts down after a preset idle time, which reduces fuel costs and reduces noise. The hourly meter stopped working, which reduced maintenance costs and increased the resale value of the machine.

3. Durability and reliability

-

The EW60 has the same quality as all Volvo machines, including a robust gearbox and axles, with high durability and robustness on the job site.

4. More convenient machine monitoring

-

The new generation of vehicle communication hardware PSR brings a new upgraded car networking service experience. You can view your machine's location information, machine condition and reports, etc., or use the Volvo ActiveCare service to understand your machine's health.

-

The Volvo Maintenance Hours Centre will provide 24 / 7 machine monitoring and notify you when preventive maintenance measures are required.

1. Quick connector

-

The machine mechanical couplings and hydraulic quick couplings allow quick and easy efficient replacement of accessories .

-

For easy field operation , quick connectors can be adapted to different of Volvo bucket , and it can be perfectly matched with a wrecking hammer and a thumb clamp .

2. Bucket

-

The range of shovels is complete, from general reinforcement shovels to trench shovels, making the machine suitable for various applications in various job sites. The shovel is strong and durable and is suitable for operations such as loose gravel, gravel, dirt and soil.

3. Impact hammer

-

Volvo's durable hydraulic breaking hammer is a perfect match for Volvo excavators. There are a wide variety of crusher tools (or drills) that are suitable for the crushing of various materials, with excellent performance, low noise and low vibration levels.

4. Thumb Clamp

-

Specially designed to match Volvo's directly assembled shovels and fast connectors, the Volvo thumb clips perform a variety of job tasks, including piling, placing, loading, lifting and moving.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE