VOLVO EC950 Classic inheritance, brand new upgrade

VOLVO EC950 Classic inheritance, brand new upgrade

The Very Large Excavator

EC950 CN4

1. Performance parameters:

|

force |

Traction force |

565 |

kN·m |

|

Bucket Digging Force - ISO |

478 |

kN |

|

|

Bucket Rod Digging Force - ISO |

420 |

kN |

|

|

Rotation torque |

343 |

kN·m |

|

|

speed |

Reverse speed |

6.9 |

r/min |

|

行走高速/低速 |

4.4/2.8 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

/ |

° |

|

Ground is higher than pressure |

/ |

kPa |

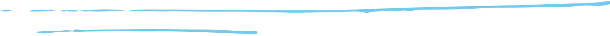

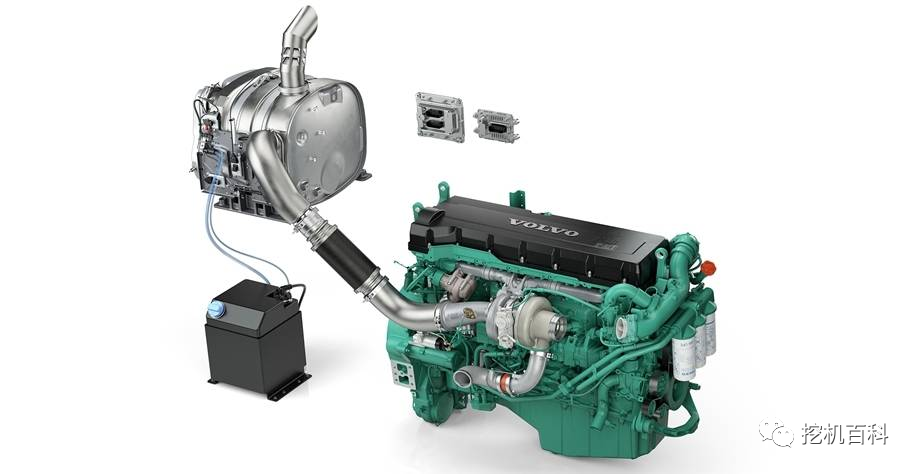

2. Powertrain:

|

Engine Model |

Volvo D16J |

|

|

rated power |

450/1650 |

kW/rpm |

|

Maximum torque |

2701/1400 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

DOC+DPF+SCR |

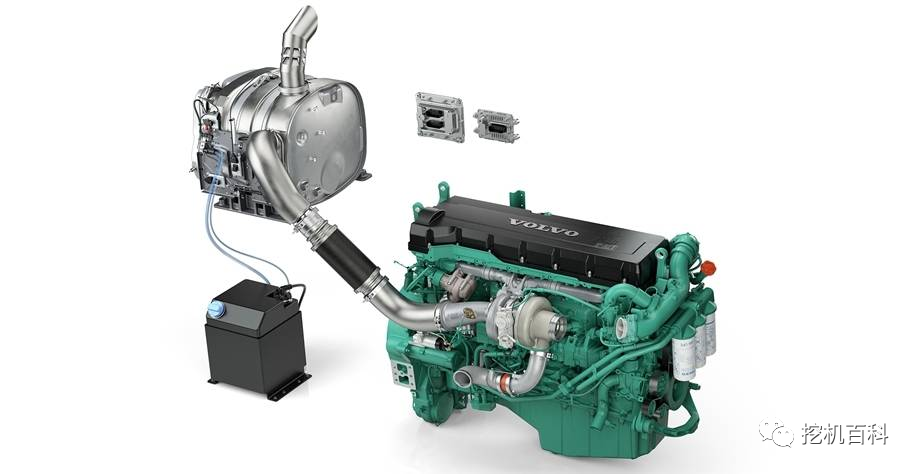

3. Hydraulic system:

|

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

Double turnaround |

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*515 1x147 |

L |

|

The overflow valve settings: |

||

|

Working Circuit |

34.3 |

MPa |

|

Turning the oil road |

28.4 |

MPa |

|

Walking the oil road |

34.3 |

MPa |

|

Leading oil road |

/ |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

7250 |

mm |

|

Fighting clubs |

2950 |

mm |

|

The shovel fighter looks |

5.6~7.0 |

m³ |

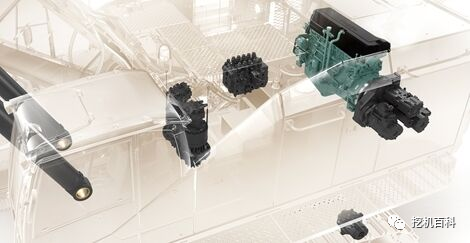

5. The chassis system:

|

Weight of weight |

16100 |

kg |

|

Number of trackpads - one side |

/ |

section |

|

Number of cogs - one side |

3 |

individual |

|

Number of support wheels - one side |

9 |

individual |

|

Running board width |

650 |

mm |

|

Chainrail steering agency - single side |

Full protection |

6. Amount of oil and water added:

|

Fuel tank |

1265 |

L |

|

Urin boxes |

95 |

L |

|

Hydraulic system |

890 |

L |

|

Hydraulic fuel tank |

460 |

L |

|

Engine oil |

52 |

L |

|

Antifreeze Solution |

74 |

L |

|

Walking brake gear oil |

2X25 |

L |

|

Reverse gear oil |

2x6.5 |

L |

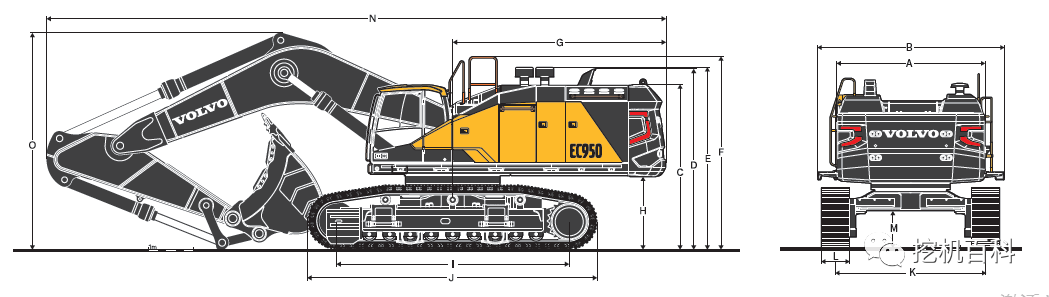

7. Form factor:

|

A |

Total upper structure width |

3485 |

mm |

|

B |

Total width (channel) |

4467 |

mm |

|

C |

Total height of the driver's room |

3655 |

mm |

|

D |

Total height of the drainage shield, |

3990 |

mm |

|

E |

Total height of oil bath prefilter |

4180 |

mm |

|

F |

Total height of guardrails |

4263 |

mm |

|

G |

Tail pivot radius |

4700 |

mm |

|

H |

Weight-to-earth gap * |

1623 |

mm |

|

I |

Wheel spacing (drive and guide wheels) |

5120 |

mm |

|

J |

Track length |

6380 |

mm |

|

K |

Track Distance (Extension) |

3550 |

mm |

|

Track length (shrink back) |

2980 |

mm |

|

|

L |

Trackboard width |

650 |

mm |

|

M |

Minimum distance from the ground * |

915 |

mm |

|

N |

Total length |

13615 |

mm |

|

0 |

Total arm height |

4840 |

mm |

|

*: No track plate teeth |

|||

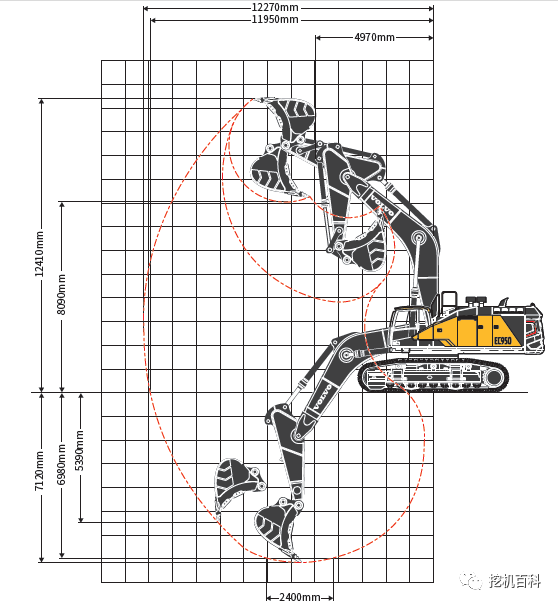

8. Operational scope:

1. Ideal for operators

-

Volvo's industry-renowned driver's room is incredibly comfortable and makes it easy to handle a tough operating environment.

-

With low noise, large space (storage and leg space) and 12 air-conditioned vents and adjustable seats, operators can maintain their energy and focus on their current job.

-

All interfaces - including levers, keyboards and LCD monitors - are ergonomically designed, with a clear field of view and a rear-view camera allowing operators to intuitively feel the powerful capabilities and durability of the machine.

2. Easy maintenance

-

Overhauls are quick and safe, allowing for maximum uptime.

-

The basic repair points are carefully designed so that customers can easily carry out repairs through easy-to-open, convenient doors and central and surrounding passageways.

3. Durable and reliable

-

The machine is standardly equipped with a robust rack structure and full-track pads that effectively protect various components in harsh application situations, thereby greatly extending service life and uptime.

-

For increased safety and durability, a certified Fall Object Protection (FOG) is also available.

4. Easy to deal with different working conditions

-

When a machine climbs a hill or walks on rough roads, a high-output walking motor and a sturdy, durable track ensure a powerful traction for the machine.

-

The aircraft has a longer track length and wider track length, and is equipped with a retractable chassis and optimized weighting to ensure a more robust and balanced aircraft that allows operators to operate easily on rough terrain.

1. Full control

-

The new generation of electrically controlled hydraulic systems allows the operator to control the machine with great ease, enabling more efficient and productive operations. The system is easy to use and uses smart technology that enables flow control based on actual requirements, thereby reducing internal losses in the hydraulic oil pipeline.

-

What's more, the EC950 is equipped with a boom swing priority valve

2. ECOPattern

-

Volvo's unique ECO mode ensures excellent fuel efficiency.

-

This mode optimizes the hydraulic system, reduces flow and pressure loss, and improves fuel efficiency while guaranteeing superior performance under most operating conditions.

3 . Give full play to their role

-

Smart engine features, such as automatic engine idling and automatic engine downtime, eliminate unnecessary fuel consumption and various types of wear, while lowering operating costs and reducing environmental impact, so that every drop of oil makes a difference.

-

The smart engine delayed shutdown feature shuts down the engine after the turbocharger cools to the right temperature, which further improves the durability and reliability of the engine.

4 . Multiple work modes

-

Volvo's unique integrated operating mode system enables optimal fuel efficiency and machine performance.

-

While maximizing efficiency, operators can also choose the working modes most appropriate to the task at hand - I (idle), F (fine), G (normal), H (heavy) and P (maximum power) modes.

1. Higher productivity

-

The EC950 is powered by Volvo's excellent electrically controlled hydraulics and offers about 7% more productivity than the previous generation. The machine's shovel capacity increased by about 7 per cent, excavator power and traction were greater, enabling higher productivity under equal working conditions.

2 . Short time , high efficiency .

-

With electronic hydraulic control, customers can greatly shorten the period of batching cycle. The optimized hydraulic system increases the power of the pump to operate quickly and smoothly.

3 . Auxiliary mining system

-

The Volvo Assisted Mining System is supported by a 10-inch Volvo Assistive Driving System display, Equipped with a set of intelligent applications that optimize the mining process, including 2D, 3D, In Field Design, and On-Board Weighing, machine productivity can be maximized.

4. More convenient machine monitoring

-

Pulse, a new in-vehicle communication system, can maximize machine uptime and reduce maintenance costs.

-

You can view your machine's location information, machine condition and reports, etc., or use the Volvo ActiveCare service to understand your machine's health.

-

The Volvo Maintenance Hours Centre will provide 24 / 7 machine monitoring and notify you when preventive maintenance measures are required.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE