VOLVO EC300 Classic inheritance, brand new upgrade

VOLVO EC300 Classic inheritance, brand new upgrade

Large excavator

EC300 CN4

Summary

Configuration parameters

Standard: ● Option: ○ Reference value: * To be refined: /

1. Performance parameters:

|

force |

Traction force |

248 |

kN·m |

|

Bucket Digging Force - ISO |

207 |

kN |

|

|

Bucket Rod Digging Force - ISO |

163 |

kN |

|

|

Rotation torque |

115 |

kN·m |

|

|

speed |

Reverse speed |

11 |

r/min |

|

行走高速/低速 |

5.6/3.6 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

° |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Volvo D8M |

|

|

rated power |

189/1600 |

kW/rpm |

|

Maximum torque |

1290/1400 |

Nm/rpm |

|

discharge volume |

/ |

L |

|

Emissions Level |

Country 4 |

|

|

Emissions technology routes |

DOC+DPF+SCR |

3. Hydraulic system:

|

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

|

|

Walking motors and gears brands / models |

/ |

|

|

Maximum traffic on the main system |

2*276 |

L |

|

The overflow valve settings: |

||

|

Execute a hydraulic circuit |

33.3/36.3 |

MPa |

|

Turning the oil road |

28.9 |

MPa |

|

Walking the oil road |

36.4 |

MPa |

|

Leading oil road |

/ |

MPa |

|

Tank specifications: |

||

|

Armed cylinder |

/ |

mm |

|

Bulk fuel tank |

/ |

mm |

|

The shovel oil tank |

/ |

mm |

4. Working appliance:

|

Move your arms |

6200 |

mm |

|

Fighting clubs |

2750 |

mm |

|

The shovel fighter looks |

1.69 |

m³ |

5. The chassis system:

|

Weight of weight |

/ |

kg |

|

Number of trackpads - one side |

/ |

section |

|

Number of cogs - one side |

2 |

individual |

|

Number of support wheels - one side |

9 |

individual |

|

Running board width |

600 |

mm |

|

Chainrail steering agency - single side |

2 |

individual |

6. Amount of oil and water added:

|

Fuel tank |

472 |

L |

|

Urin boxes |

50 |

L |

|

Hydraulic system |

385 |

L |

|

Hydraulic fuel tank |

215 |

L |

|

Engine oil |

30 |

L |

|

Antifreeze Solution |

44 |

L |

|

Walking brake gear oil |

2*6 |

L |

|

Reverse gear oil |

6.1 |

L |

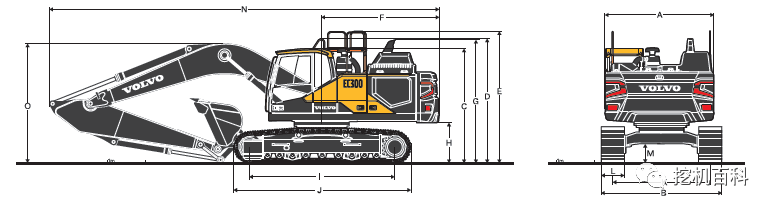

7. Form factor:

|

A |

Total upper structure width * |

2890 |

mm |

|

B |

Total width |

3190 |

mm |

|

C |

Total height of the driver's room |

3110 |

mm |

|

D |

Total armrest height |

3360 |

mm |

|

E |

Total height of the guardrail (expands) |

3570 |

mm |

|

E' |

Total armrest / guardrail height (folding) |

3090 |

mm |

|

F |

Tail pivot radius |

3120 |

mm |

|

G |

Total height of the drainage shield |

3010 |

mm |

|

H |

Weight-to-earth gap * |

1105 |

mm |

|

I |

Wheel spacing (drive and guide wheels) |

4015 |

mm |

|

J |

Track length |

4865 |

mm |

|

K |

Track length |

2590 |

mm |

|

J |

Trackboard width |

600 |

mm |

|

M |

Minimum distance from the ground * |

475 |

mm |

|

N |

Total length |

10550 |

mm |

|

O |

Total arm height |

3430 |

mm |

|

*: No track plate teeth |

|||

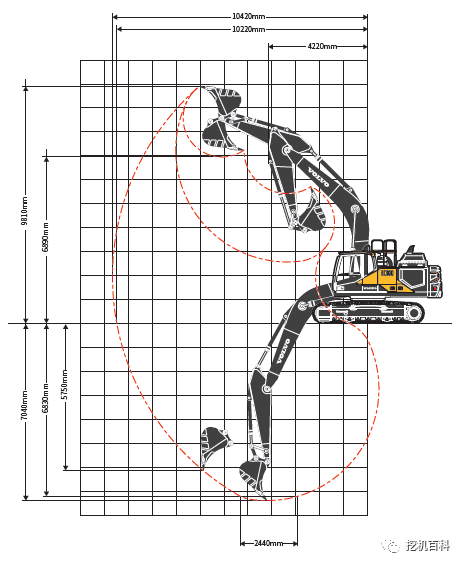

8. Operational scope:

Higher fuel efficiency

1. It is more in line with national standards.

-

The EC300 is equipped with a Volvo D8 engine that meets the "National Four" emission standard. Since its birth in 2014, the engine has gone through the rigors of the global market. With a decade of carefully honed technological advantages, its overall strength continues to strengthen, providing solid and reliable product quality and satisfactory operational efficiency to users around the world.

2. Higher productivity

-

The improvements in engine power and hydraulic performance have helped to shorten the cycle time and allow more work to be done. Exceptional stability, new motion prioritization features, arms down speed control, and faster lift speeds further increase machine productivity.

3. Precision control

-

Volvo Active Control technology automates arms and shovel movements, making the excavation process more accurate and doubling the speed, resulting in a significant increase in productivity. Simply set the slope on the Volvo Assisted Driving System display and press a button to get things going - all controlled with a single handle. The Volvo Assisted Mining System is supported by the 10-inch Volvo Assistive Driving System display, which allows for greater machine productivity. The system is equipped with a set of intelligent applications that optimize the excavation process, including 2D, 3D, In Field Design and On-Board Weighing.

4. Response is faster

-

The response time is reduced by an electric handle and a fully electric walking pedal.

-

Arm / pivot and arm / walk prioritization functions further improve the control of the machine, enabling the operator to prioritize one function.

-

When performing a fine job requiring high manipulation accuracy, the operator can easily adjust the arms' descent rate to meet the job requirements.

Designed for safety and comfort

1. More Safety and Security

-

With the help of Volvo Active Control, operators can easily set turn fences, height limits and depth limits through the Volvo Assisted Driving System. This helps the machine to stay away from side obstacles, hanging obstacles (power lines, etc.) and various hazards underground (such as pipes, cables, etc.).

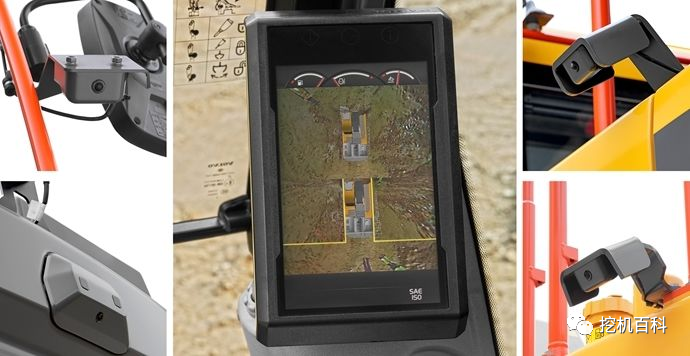

2. Take in everything at a glance

-

Thanks to rear-view cameras, operators can get a better view. In addition, the optional Volvo panoramic camera provides a real-time view of the machine through front, rear and side-view cameras, ensuring that the machine can be rotated more safely during operation, especially in a narrow area.

3. Control is smoother

-

The new large and small arm jitter technology reduces machine jitter to a greater extent, so the operator is in a more comfortable state, which helps improve productivity. The operator can control the movement of the machine using the handlebar wheel (rather than the pedal) through the comfort driving control function. It can further reduce fatigue.

4. Custom Control Modes

-

Once you customize the settings, including the easy choice of the preferred control mode from the monitor, the machine can work at any time. In addition, the operator can set another quick switch through the new "long press" function on the handle. With the L8 handle, you can create quick switches with hydraulic priority functions.

Keep improving

1. Reduce maintenance costs

-

The new electrically controlled hydraulic system requires fewer hoses, thus reducing the need for dockings, minimizing maintenance requirements and increasing reliability.

2. Urea injections are easier

-

The new spray shield on the urea tank makes filling faster and easier, while also reducing the risk of spillage and subsequent corrosion.

3. Calmly respond to challenges

-

This heavy production machine has excellent strength and durability and a strong chassis design with reinforced steering wheel brackets, track tracks and support wheels.

-

A shovel joint with reinforced steel. The selection of heavy mounting bottom guards and easily changed bolt-tight and wear-resistant plates at the end of the arms ensures that the excavator can navigate even in more demanding worksites.

Exploiting the potential of machines

1. Pure accessories are essential

-

Use a variety of ready-made spare parts that have been tested and certified, all with a Volvo warranty, to guarantee your productivity and machine uptime.

-

Using Volvo Pure Parts helps to extend the life of your machine and improve its lasting performance, thereby contributing to a higher return on your investment.

2. Maintaining machine performance

-

Perform maintenance on schedule and choose a flexible maintenance program to protect your machine.

3. Easily monitor the state of your machine

-

The new generation of vehicle communication hardware PSR brings a new upgraded car networking service experience. WOW + Smart Cloud platform enables you to optimize your fleet and maximize productivity through real-time tracking, machine state in service, geographic / temporal fence management, and equipment utilization reporting.

-

The system provides machine-related reports that show how each machine is being used and how efficiently the hands are working, and can help you determine training needs.

-

You can view the real-time working condition of the equipment through the Volvo + wisdom cloud platform or the Volvo construction equipment APP, Wo peace of mind report, maintenance / alarm reminder, etc. The Volvo Maintenance Hours Centre provides 24 / 7 machine monitoring, provides monthly reports, and notifies you when preventive maintenance measures need to be taken.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE