SANY SY980H Classic inheritance, brand new upgrade

SANY SY980H Classic inheritance, brand new upgrade

The Very Large Excavator

SY980H

Summary

Lifting mountains and lifting mountains is a pioneer of strength.

Main technical specifications:

Power: 478 / 1800 kW / rpm

Machine weight: 94500kg

Bucket capacity: 6.5 m3

Configuration parameters

Standard: ● Option: x To be perfected: / Reference value: *

1. Performance parameters:

|

force |

Traction force |

640 |

kN·m |

|

Bucket Digging Force - ISO |

495 |

kN |

|

|

Bucket Rod Digging Force - ISO |

405 |

kN |

|

|

Rotation torque |

/ |

kN·m |

|

|

speed |

Reverse speed |

7 |

r/min |

|

行走高速/低速 |

4.3/3.0 |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

degree |

|

Ground is higher than pressure |

132 |

kPa |

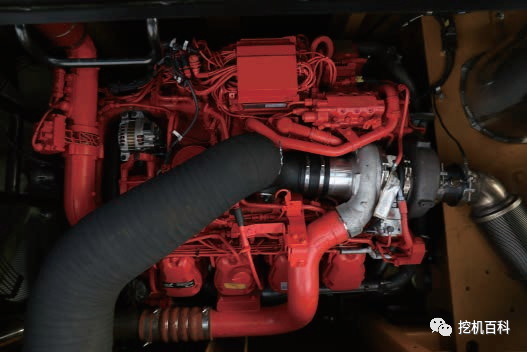

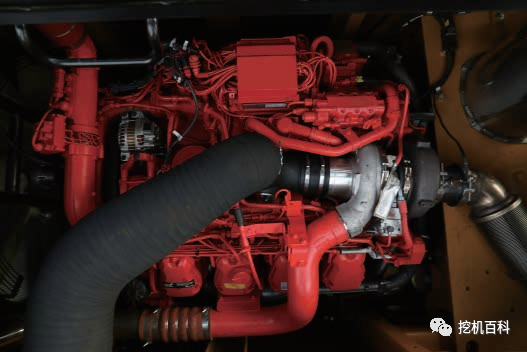

2. Powertrain:

|

Engine Model |

Kenyan DC16 |

|

|

rated power |

478/1800 |

kW/rpm |

|

Maximum torque |

3260/1400 |

Nm/rpm |

|

discharge volume |

16.4 |

L |

|

Emissions Level |

Country 4 |

|

|

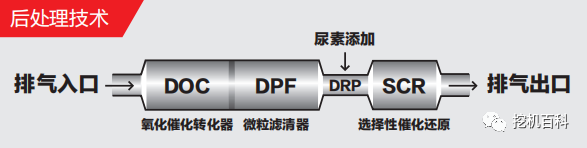

Emissions technology routes |

DOC+DPF+SCR |

|

|

With VGT technology, the dynamic response is fast, the fuel consumption is low, to meet the needs of both power and economy. |

||

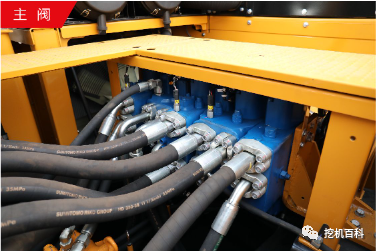

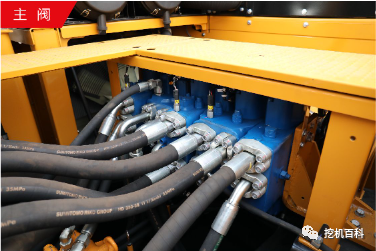

3. Hydraulic system:

|

The technical route |

All-electric control |

|

|

Main Pump Brand / Model |

/ |

|

|

Main pump discharge |

/ |

cc |

|

Main valve brand / model |

/ |

|

|

Reverse motors and gearing brands / models |

/ |

|

|

Walking motors and gears brands / models |

/ |

|

|

It carries a fully electrically controlled hydraulic system, a large displacement main pump with pressure cutting function, and reduces overflow loss. High-throughput electric control and combined closure core, low pressure loss and coordination. The barrel oil tank has a capacity of 230. |

||

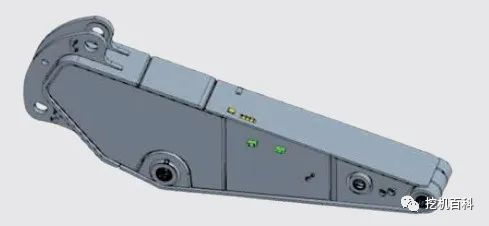

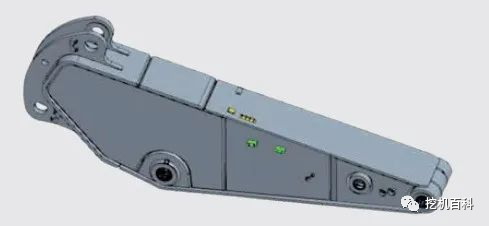

4. Working appliance:

|

Move your arms |

7250 |

mm |

|

Fighting clubs |

2920 |

mm |

|

The shovel fighter looks |

6.5 |

m³ |

5. The chassis system:

|

Weight of weight |

14000 |

kg |

|

Number of trackpads - one side |

51 |

section |

|

Number of cogs - one side |

3 |

individual |

|

Number of support wheels - one side |

9 |

individual |

|

Running board width |

650 |

mm |

6. Amount of oil and water added:

|

Fuel tank |

1180 |

L |

|

Hydraulic system |

/ |

L |

|

Hydraulic fuel tank |

830 |

L |

|

Engine oil |

50 |

L |

|

Cooling system |

82 |

L |

|

Walking brake gear oil |

2x18 |

L |

|

Reverse gear oil |

2x14 |

L |

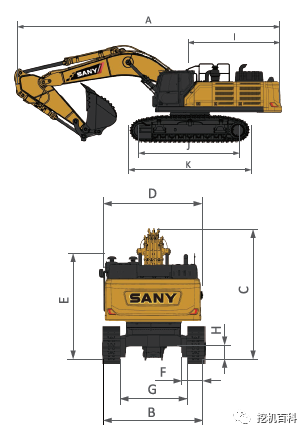

7. Form factor:

|

A |

Total Length (at the time of transport) |

13850 |

mm |

|

B |

Total width |

4460/3700 |

mm |

|

C |

Total height (at the time of transport) |

5300 |

mm |

|

D |

Upper width |

3490 |

mm |

|

E |

Total height (top of the cab) |

3860 |

mm |

|

F |

Standard track plate width |

650 |

mm |

|

G |

gauge |

3510/2750 |

mm |

|

H |

Minimum distance from the ground |

945 |

mm |

|

I |

Tail pivot radius |

4668 |

mm |

|

J |

Track grounding length |

5070 |

mm |

|

K |

Track length |

6350 |

mm |

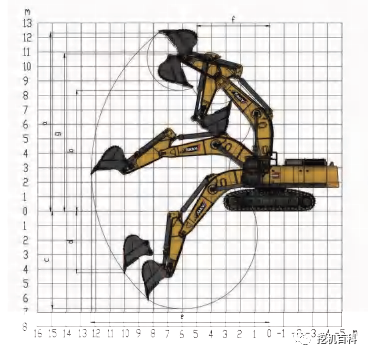

8. Operational scope:

|

a. |

Maximum excavation height |

12450 |

mm |

|

b. |

Maximum removal height |

8205 |

mm |

|

c. |

Maximum excavation depth |

7045 |

mm |

|

d. |

Maximum digging vertical arm depth |

4250 |

mm |

|

e. |

Maximum excavation radius |

12530 |

mm |

|

f. |

Minimum rotation radius |

5085 |

mm |

|

g. |

Maximum height at minimum rotation radius |

10650 |

mm |

Functional configuration

Standard: ● Option: x To be perfected: / Reference value: *

1. Engine:

-

High power engine

-

Dynamic tuning mode control

-

Separate radiators

-

24V / 7.0kW Starter Motor

-

60A AC Motor

-

Oil bath air filter

-

Lubrication oil filter

-

Level 3 Fuel Filter

-

Oil cooler

-

Heater sub-water tank

-

Fan curtain

-

Automatic idling system

-

High-capacity urea container

-

SCR post-processing

-

Urine pump

2. Driver's Room:

-

Automotive-grade cockpit

-

Strengthened light glass windows

-

Silicone rubber shock absorbers

-

Top, front window and left window (openable)

-

Back window emergency safe exit

-

Rain wiper (with a cleaning device)

-

Multifunctional Air Suspension Seat

-

Feet boards, floor mats

-

Speakers, rear view mirrors

-

Seat belts, fire extinguishers

-

Drinking cup seats, lanterns

-

Escape hammer

-

Storage boxes, document bags

-

Lead control cutting rod

-

Completely automatic air conditioning

-

Emergency stop switch

-

Top protective net + front protective net

3. The lower walking body:

-

Strengthened walking motor protection plate

-

Strengthened suspension rack

-

Running belt tightening device

-

drive wheel

-

Chain lifters and heavy lifting wheels

-

Strengthened chain tracks (with shaft seal)

-

650mm two-rib track plate

-

Strengthened double-layer side pedals

-

Protective covering plate

4. Hydraulic system:

-

Control valve (with main overflow valve)

-

Control valve backup oil outlet

-

Oil absorption filter

-

Oil leak filter

-

Reverse oil filter

-

Leading Filter

-

Hydraulic shock relief blind pipe

-

Independent oil spill

5. Front-end working devices:

-

French sales

-

Casting rod

-

Fully automated central lubrication system

-

Dust sealing rings (trawl solder configuration)

-

Strengthening the fully wrought box arms

-

Strengthening fully wrought box braces

-

Forging arm fork

-

Crooked cock teeth / sharp cock teeth

-

Rolling disk lubrication system

6. The upper pivot platform:

-

Fuel Level Sensor

-

Hydraulic Oil Level Meter

-

toolbox

-

Reverse parking brake

-

Rearview mirror (right)

-

Panoramic camera

-

Driver Room Alarm Light

7. Alarm lights:

-

Controller failure

-

The pump pressure is abnormal

-

Abnormal pre-emptive pressure for each action

-

The power supply voltage is abnormal

-

Insufficient oil pressure, overheating of engine coolant

-

The accelerator knob failed

-

Insufficient amount of fuel.

8. Supervisory control system instrument:

-

Standard GPS

-

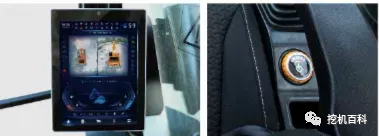

Touch color 10-inch display screen

-

The Iveco system

-

Hour meter, fuel level gage of fuel tank

-

Engine Coolant Temperature Table

-

Oil pressure gauge

-

Smart safe boxes

9. Others:

-

High-capacity batteries

-

Lockable ceiling cover

-

Central Passage

-

Anti-sliding pedals, handrails and sidewalks

-

Fuel system exhaust pump

A new look

1. Intelligent :

-

Equipped with 10.4 inch intelligent display screen, integrated air conditioning, radio, Bluetooth, GPS and other functions, standard with a button to start the machine, support fault detection and alarm, intelligent debugging and diagnosis, a new button to invite function, more safe and intelligent.

2. Air conditioning upgrades:

-

The new air conditioning wind tunnel optimizes the outlet position, the cooling effect is 10% higher than the previous model, the condenser volume is 30% higher than that of the previous model. The air conditioning can be cleaned on-board and easy to maintain.

3. C12 Driving Room:

-

The newly upgraded driver's room is developed according to the five features of "intelligent connectivity, intelligent interaction, intelligent construction, intelligent driving, and intelligent maintenance," to enhance entertainment, interaction and technology.

-

The driving room size is 25mm wider than the previous generation, and the space is larger. The front window is 10 percent wider than the previous generation, the glass area of the vehicle is 10 percent larger, and the view is wider.

4. Interior upgrades:

-

A newly upgraded interior, with a suspension four-seat armrest, cup seat, refrigerator, 24V electrical outlet, USB interface, etc., introduced static and dynamic comfort standards for automobiles, and a newly developed "12h without fatigue" large damping suspension and vibration-reducing seat.

5. Sealing upgrade:

-

The driver's sealing structure is optimized and upgraded, the leakage and indoor temperature are significantly reduced, effectively resolving the pain point of graying in the driver's room under harsh working conditions, and the thermal comfort is increased by 10% compared to the previous generation.

6. Safe and reliable:

-

Skeleton reinforced cabs have a 30% higher safety performance than ordinary cabs.

-

Equipped with emergency stop switch, anti-skid cover, anti-gravel side door, etc., to further enhance the safety of equipment mining operations.

new technology

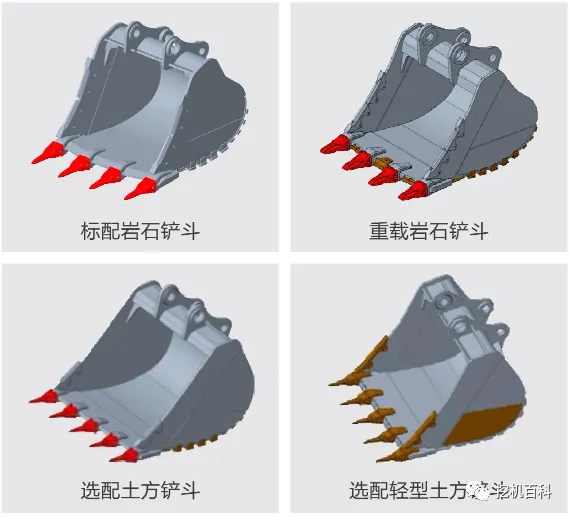

1. The shovel upgrade:

-

Standard 6.5m3 bucket, can be equipped with 90 tons 240 / 250 breaking hammer, to meet the needs of heavy load conditions.

-

Four series of shovels can be configured to meet "one situation, one fight," improve construction efficiency, easily handle multiple complex situations, and enhance product value and customer profitability.

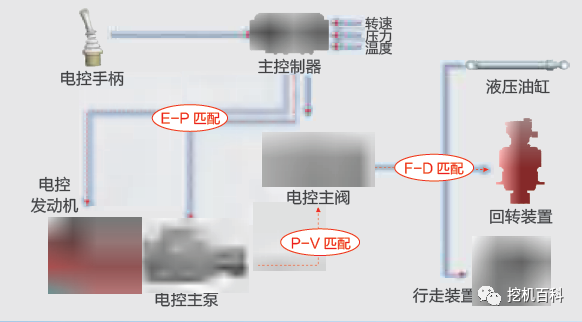

2. Full electric control system:

-

The use of all-electric control integrated matching technology (ICT-Integrated Control Technology) mainly includes E-P, P-V, FD and ECA technology, that is, engine and main pump matching technology, main pump and main valve matching technology; flow distribution technology; electric control auxiliary technology; armless power decentralization technology; independent oil and water dispersion control.

3. Automatic lubrication:

-

The electric filling machine is convenient to operate , saves time and effort , does not waste oil , and ensures that the oil is not polluted . Using the special barrel of refined oil products , the product can be placed directly on the grease in the barrel , and the grease filling can be completed by power .

-

This product has been patented as a national invention and a utility model.

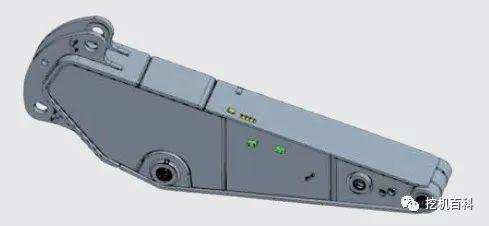

4. Strengthening of workpiece structural components:

-

The 20,000-hour work unit technology is fully applied to ensure high reliability and longer life of the work unit.

-

Improving the barrel mechanism, increasing the system pressure and shut-lock pressure, increasingly the barrel oil tank to 230, and increasing barrel excrement power.

5. Get out of the car enhanced:

-

Use of 100-ton four-wheel to get off, increase the axle diameter, reduce the bearing surface pressure, solid guide wheel wheel body, large walking reducer, load carrying capacity greatly improved.

Maintenance & Service

-

The joint specialized manufacturers have developed long-life oil, diesel filter, and hydraulic oil, which has doubled the customer maintenance cycle and reduced the maintenance cost.

-

In response to the harsh working conditions in the mine, the convenient design of maintenance replacement is strengthened, "large space, easy to carry out," and the operating space for various maintenance changes is increased by 20-30%.

-

The dual pre-filter air filter system reduces the inlet resistance, improves the maintenance cycle, has low maintenance cost, and is adapted to high dust work conditions.

-

Standard filter element annunciator, real-time monitor and master the state of health, more intelligent and safe.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE