SANY SY75C Classic inheritance, brand new upgrade

SANY SY75C Classic inheritance, brand new upgrade

Small excavator

SY75C

Summary

Longevity, the pioneer of wealth.

SY75C is a star product of Sany Heavy Machinery, with high sales and large market share of single models.

SY75C national four machine around "new power," "new shape," "new technology" for a comprehensive upgrade, lower fuel consumption. It is suitable for small earth and stone projects such as municipal construction, urban renewal, house construction, agricultural land, water conservation, etc., with the goal of further improving the return on investment of customers.

Main technical specifications:

Power: 55 kW / 2000 rpm

Machine weight: 7350 kg

Bucket capacity: 0.3 m3

Configuration parameters

Standard: ● Option: ○ Reference: *

Bucket digging force 56 kN

Arm digging force 38 kN

Rotary speed 11.5 r / min

Walking speed 4.4 / 2.4 km / h

Slope ability 70 per cent (35 per cent)

Ground specific voltage 33 kPa

Powertrain:

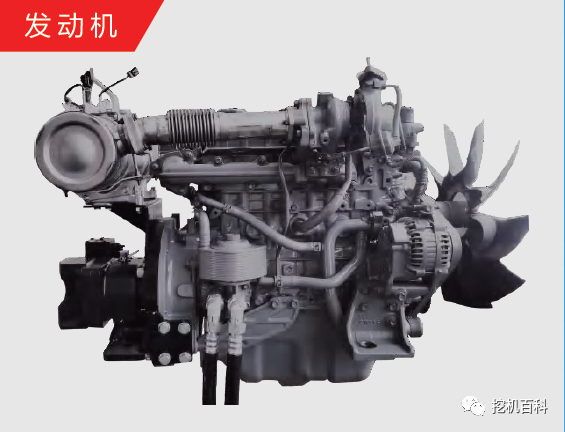

Engine Isuzu 4 JG3X

Frontal fixed power 55 kW / 2000 rpm

Displacement 2.999L

Emissions Standards Country IV

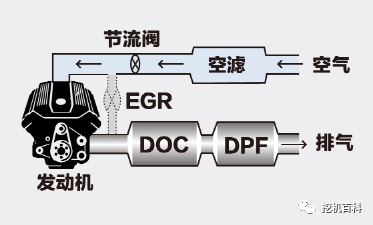

Technical route DPD + EGR

Hydraulic system:

Technical route load-sensitive system

The arms and arms are:

1650mm standard rod

○ 2050mm Extended Rod

●0.3 m³ 铲斗

○0.12 m³ 窄斗(450mm)

○ 0.25 m3 standard bucket (650 mm)

○ 0.25 m3 reinforced bucket (680 mm)

○ 0.28 m3 standard bucket (720 mm)

○ 0.28 m3 Wider bucket (800 mm)

○0.32 m³ enlarged bucket (800 mm)

The chassis system and structure:

450 mm standard track (steel / rubber)

39 tracks (one side)

● 5 axles on each side

● 1 chain wheel on each side

Oil and water injection:

Fuel tank 150 L

Hydraulic Tank 120 L

Engine oil 9.5L

Antifreeze 6.5 L

Final drive 2 × 1.2L

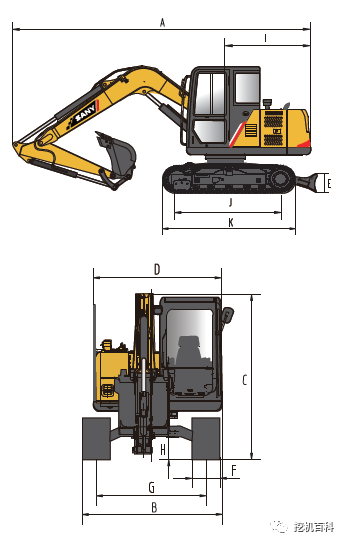

Form factor:

A. Total transport length 6120 mm

B. Total width 2220 mm

C. Total transport height 2675 mm

D. Upper width 2040 mm

E. Bulldozer height 405 mm

F. Standard track width 450 mm

G.轨距 1750 mm

H. Minimum ground clearance 380 mm

I. Rear radius of gyration 1800 mm

J. Wheelbase: 2195 mm

K. Track length 2820 mm

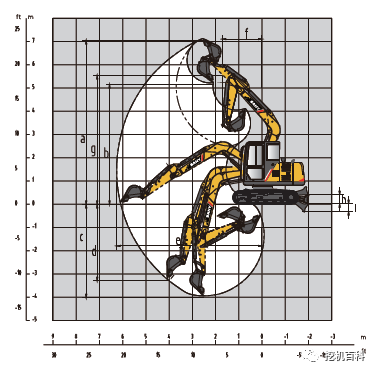

Operational scope:

A. Maximum excavation height 7015 mm

B. Maximum unloading height 5110 mm

C. Maximum excavation depth 4065 mm

D. Maximum vertical excavation depth 3335 mm

E. Maximum excavation radius 6240 mm

F. Minimum radius of gyration 1720 mm

G. Maximum height at minimum radius of gyration 5505 mm

H. Maximum ground clearance 480 mm for bulldozer lift

I. Maximum depth of bulldozer 417 mm

New upgrade - superior performance

1. Powertrain:

-

Equipped with Isuzu 4JG3X engine, the fixed power of 55kW, the power surplus is more sufficient, and the hydraulic power is not reduced below 4000m plateau. With high-pressure co-rail technology, fuel consumption is lower.

-

Mature DPF post-treatment + 8 hours automatic regeneration control strategy, to ensure that the accumulation of particles in a low state, reduce the number of standby manual regeneration, worry and durable.

2. DPD + EGR technical route:

-

Part of the exhaust gas is recirculated into the gas admittance system, where it is mixed with fresh air and burned to suppress NOX production.

-

EGR is upgraded from tubular to laminated, cooling faster.

3. Hydraulic system:

-

With a load-sensitive system, the operation efficiency is higher, the control performance is better, and the flat surface performance is superior.

-

The main valve diameter is increased, the pressure loss is reduced by 15%, the valve oil channel is optimized, the liquid power is reduced, and the operation energy efficiency is greatly improved.

Optimization of structural components - durability

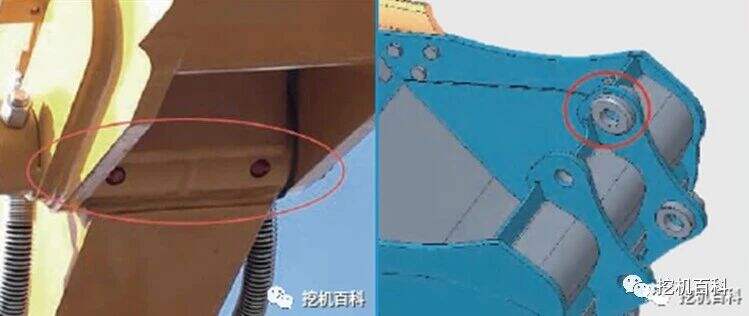

1. Arm, pole, and shovel upgrades:

-

The axial length of the moving arm body is increased, the stiffness is increased and the reliability is greater. Optimize the position of the butter mouth of the braid from the side to the lower side of the braide for easy maintenance.

-

The bucket is widened and the bucket capacity is increased to 0.3 m3; Optimize the barrel structure and increase the lifetime; The material of the bucket ear plate is upgraded to G70 / Q460C, and the wear resistance is greatly improved.

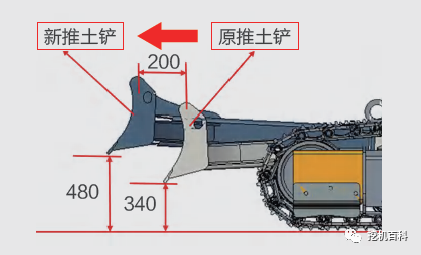

2. The bulldozers escalated

-

The shovel is lengthened and lifted, the height increased to 480 mm, and the angle increased to 28.5 °, eliminating walking obstacles.

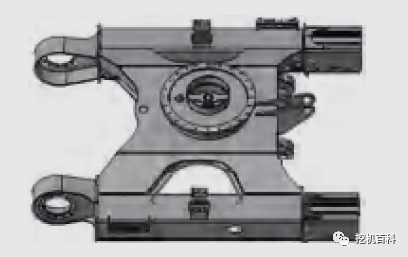

3. Get off the chassis to strengthen

-

The reinforced integral welded X-shaped lower frame has more advantages in safety and reliability than H-shaped, and extends service life.

Upgrade the driver's room - a new experience

1. Sealing improvements:

-

Using a modular perforation design of wire duct ducts, an upgrade of sealing tape, a secondary filling of unwelded areas, etc., the cabin sealing is greatly improved to solve the dust annoyance.

2. Air conditioning upgrades:

-

Automotive-grade vents are used to optimize the position of air conditioning vents and are more ergonomic, and are controlled from head to toe at a constant temperature.

The 3.7-inch smart touch screen:

-

The screen integrates functions such as Bluetooth, USB, telephone, recorder, etc., and can freely switch multimedia audio source equipment. Vehicle condition information can be viewed at any time, the air conditioning temperature and wind speed can be adjusted by screen control, making it more technologically intelligent.

4. Interior upgrades:

-

The interior is designed in a new way, with the water cup positioned in front of the right lever to reduce wind tunnel space on the right side. The multi-function panel, one button to start the machine and the throttle knob two is made one, the standard equipment water cup, 12V power supply port, USB interface and so on, more humanized.

5. Deep mining field optimization:

-

The beam of the front window of the driving room is moved down 117 mm, and the view of the deep excavation is better.

6. Human / Mechanical Engineering Analysis Assistance Design

-

The thick waist support on both sides of the back is designed to increase waist support and reduce spinal burden. It is easier to ride. Back and rear, hand support, back and headrest are adjusted in 8 directions. Comfort is better. Universality is good

Functional setup

Standard: ● Option: ○

Engine:

-

S, L, B mode control

-

24V / 3.2kW Start Motor

-

30A AC Motor

-

Air Prefilter

-

Dry double filter air filter

-

Cylindrical lubrication oil filter

-

Bulk fuel filter

-

Heat heater with protective net

-

Heater sub-water tank

-

Fan curtain

-

Isolated engines

-

Automatic idling system

-

Oil and water separator

Driver's Room:

-

Soundproofed steel cab room

-

Strengthened light glass windows

-

4 silicone oil rubber vibration relief supports

-

Open front enclosure and left window

-

Back window emergency safe exit

-

A silent rain wiper with a cleaning machine

-

Adjustable reclining seat withdjustable armrests

-

Screen-controlled integrated radio

-

Feet boards, floor mats

-

speaker

-

Seat belt, fire extinguisher, escape hammer

-

Water cup seat, reading lamp

-

12V power port, USB interface

-

Lead control cutting rod

-

Air Conditioner

○ Alarm light

The lower walking body:

-

Walking motor pads

-

Slip-on hydraulic tightening mechanism

-

Piston-connected drive wheels

-

Support wheels and chain wheels

-

Strengthening the chain link

-

450mm three-rib track

-

Bottom panels

Alarm system:

-

The oil pressure is too low

-

Fuel levels are too low

-

The coolant temperature is too high

-

Filter blockage

-

An engine car

-

Voltage below level

-

The voltage is too high.

Supervisory control system instrument:

-

7-inch touch display screen

-

Fault diagnosis and alarm system

-

Hour gauge, fuel level gage

-

Engine coolant temperature

-

Car phones and multimedia

-

Automatic idling system

Others:

-

Double electric bottle

-

Lockable front and rear hood

-

Lockable fuel filling cover

-

Anti-slip tape, handrails

-

Walking direction markers on the walking rack

-

LED Work Light

○ Crushing hammer pipeline, fast switch pipeline

○ Fuel injection pump

○ Power main switch

○ Walking alarm light

Hydraulic system:

-

Control valve with primary overflow valve

-

A backup oil outlet for the control valve

-

Oil absorption filter

-

Reverse oil filter

-

Leading Filter

Front-end working devices:

-

French sales

-

Welding joints

-

All shovels are soldered with dust sealing rings

-

All-welded box arms

-

Completely wrought box handle

The upper pivot platform:

-

Fuel Level Sensor

-

Hydraulic Oil Level Meter

-

toolbox

-

Reverse parking brake

-

Counterweight

Easy maintenance

-

The wide area covering is opened by means of opening, and after opening it can stand on the ground for daily maintenance and maintenance, and the repair is convenient and close to.

-

Adjust the height of the lifting hole to avoid the hydraulic pipe, prevent the lifting line from pressuring the hydraulic piping, and make lifting more convenient.

-

The top of the hydraulic oil tank is exposed, and the hydraulic fuel tank breath valve and refueling mouth are external to facilitate later maintenance.

-

The gas admittance system is optimized, and the position of the air filter is arranged in the engine compartment, which makes the later maintenance more convenient.

-

The manifold fuel tank pipeline is improved, and the inlet and outlet pipes are placed under the tank to facilitate high-ceiling operations.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE