SANY SY335BH Classic inheritance, brand new upgrade

SANY SY335BH Classic inheritance, brand new upgrade

Large excavator

SY335BH

Summary

Ultimate efficiency loading tool

SY335BH is a 33T earth-moving excavator specially designed for earthwork , which is the focus of Sany Heavy Machinery . Through a series of measures , such as " optimizing the main pump control curve , optimizing the bucket shape and improving the coordination , " to achieve " reducing fuel consumption " and " improving efficiency , " it has been well received by customers since its launch .

The all-new SY335BH Tier 4 engine focuses on "new power,""New style" and "new technology" are fully upgraded, and the configuration of "short arm large bucket" can instantly enhance the digging force, speed is faster, to "pursue the ultimate efficiency" as the ultimate goal, to meet customer customized needs.

Main technical specifications:

Power : 120 kW / 1900 rpm

Engine weight : 32500 kg

Drum capacity: 2.0 m³

Configuration parameters

Standard : ● Optional : ○ Reference : * To be updated : /

Performance parameters:

|

force |

Traction - High Speed |

/ |

kN·m |

|

Traction - Low Speed |

/ |

kN·m |

|

|

Rotation torque |

/ |

kN·m |

|

|

Shovel excavator power |

192.7 |

kN |

|

|

Fighting pole exertion power |

172.2 |

kN |

|

|

speed |

Reverse speed |

9.5 |

r/min |

|

Traveling at high speed |

6.0 |

km/h |

|

|

Reduce speed as you go |

3.5 |

km/h |

|

|

noise |

Operator voice pressure |

/ |

dB(A) |

|

External sound pressure of the machine |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

degree |

|

Ground is higher than pressure |

60.3 |

kPa |

Powertrain:

|

Engine Model |

Isuzu 6HK1 |

|

|

rated power |

210/1900 |

kW/rpm |

|

Maximum torque |

1080/1500 |

Nm/rpm |

|

discharge volume |

7.79 |

L |

|

discharge |

Country 4 |

|

|

The technical route |

EGR (no urea) |

-

The turbocharger is upgraded to VGT ( Variable Sectional Turbocharger ) , with short response time , less drop in speed , less fuel consumption loss , and better performance at high altitude .

-

The rail pressure is increased from 130Mpa to 200Mpa , the combustion is more complete , the fuel consumption is better .

-

The EGR is upgraded to laminated type, which improves cooling capacity, increases air intake and reduces fuel consumption.

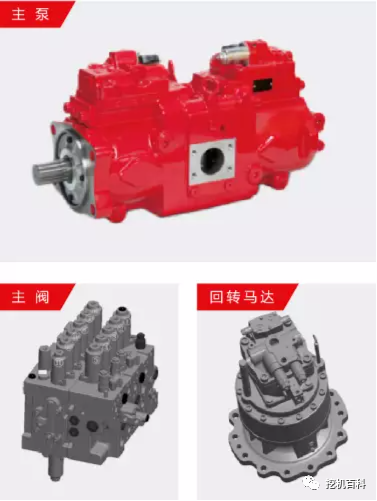

Hydraulic system:

|

The technical route |

Fully electrically controlled hydraulic technology |

|

|

Main Pump Model |

/ |

Hengli * |

|

Main pump discharge |

180 |

cc |

|

Main valve model |

/ |

Hengli * |

|

Model of rotary motor |

/ |

|

|

Reverse motor decelerator |

RG23 |

|

|

Model of walking motor |

/ |

|

|

Walking motor decelerator |

/ |

-

Using full electronic control hydraulic technology to optimize the boom and bucket valve return area and adjust the logic valve to improve coordination and leveling performance .

-

Increase the buffer valve of the boom , optimize the return oil area of the travel valve , eliminate travel speed impact .

-

The reducer is upgraded to RG23 reducer, and the rotary device is increased by 12% rotary capacity。The driving force of the machine rotation is increased, the working ability on the slope is improved, and the rotation starting speed is accelerated.

Working appliance:

|

Move your arms |

6150 |

mm |

|

Fighting clubs |

2900 |

mm |

|

The shovel fighter looks |

2.0 |

m³ |

|

Standardize a earthen cube and select a rock cube |

||

The chassis system:

|

Weight of weight |

5800 |

kg |

|

Number of trackpads |

49 |

One / One Side |

|

Standard performance belt |

600 |

mm |

|

Number of torches |

2 |

One / One Side |

|

Number of support wheels |

9 |

One / One Side |

Oil and water injection amount :

|

Fuel tank |

540 |

L |

|

Hydraulic system |

/ |

L |

|

Hydraulic fuel tank |

415 |

L |

|

Engine oil |

36 |

L |

|

Antifreeze Solution |

50 |

L |

|

Walking brake gear oil |

2x6.3 |

L |

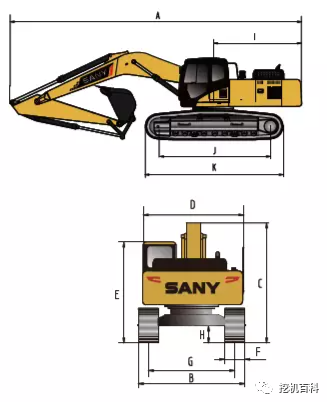

Overall dimensions :

|

A. |

Total Length (at the time of transport) |

10700 |

mm |

|

B. |

Total width |

3190 |

mm |

|

C. |

Total height (at the time of transport) |

3470 |

mm |

|

D. |

Upper width |

3175 |

mm |

|

E. |

Total height (top of the cab) |

3280 |

mm |

|

F. |

Standard track plate width |

600 |

mm |

|

G. |

gauge |

2590 |

mm |

|

H. |

Minimum distance from the ground |

550 |

mm |

|

I. |

Tail pivot radius |

3315 |

mm |

|

J. |

Track grounding length |

4134 |

mm |

|

K. |

Track length |

5040 |

mm |

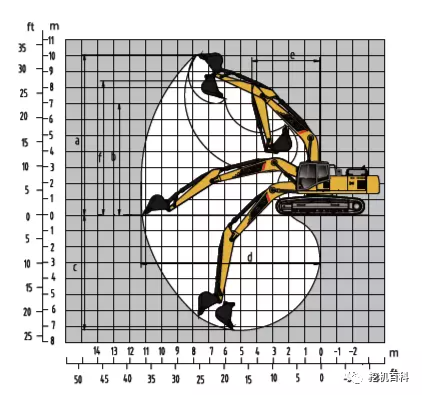

Scope of work :

|

a. |

Maximum mining height |

10248 |

mm |

|

b. |

Maximum removal height |

7205 |

mm |

|

c. |

Maximum digging depth |

6571 |

mm |

|

d. |

Maximum extension radius |

10444 |

mm |

|

e. |

Minimum rotation radius |

4000 |

mm |

|

f. |

Maximum height at minimum rotation radius |

8405 |

mm |

Functional configuration

Standard: ● Option: ○

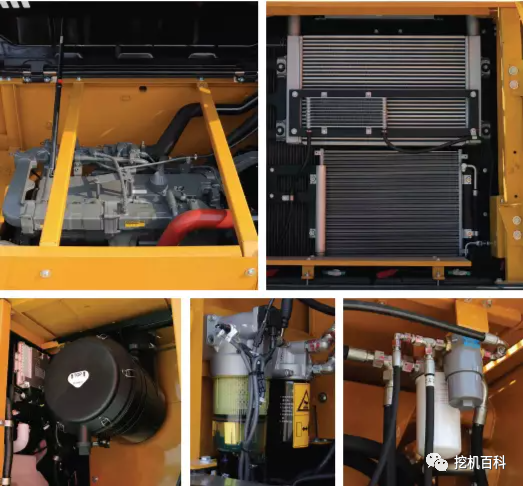

Engine:

-

Isolated engines

-

Dynamic tuning mode control

-

Heatsink (with full protective net)

-

24V / 5kW Start Motor

-

50A AC motor

-

Dry double filter air filter

-

Lubrication oil filter

-

Level 2 Fuel Filter

-

Oil cooler

-

Heater sub-water tank

-

Fan curtain

-

Automatic idling system

-

Preheat plug (for starter in cold weather)

-

4000m operating altitude

-

Model of work (fuel efficient, standard, robust)

-

Working at two speeds

Driver's Room:

-

Ultra-silent frame cab room

-

Strengthened light glass windows

-

Silicone rubber shock absorbers

-

Openable top, front enclosure window and left window

-

Rain wiper (with a cleaning device)

-

Multiple adjustable seats

-

Feet boards, floor mats

-

speaker

-

Seat belts, fire extinguishers

-

Drinking cup seats, lanterns

-

Escape hammer

-

Storage boxes, utility bags

-

Lead control cutting rod

-

Completely automatic air conditioning

-

○ Front protective net

The lower walking body:

-

Walking motor pads

-

H-type track guide mechanism

-

Slip-on hydraulic tightening mechanism

-

Piston-connected drive wheels

-

Chain lifters and heavy lifting wheels

-

Strengthened chain rails with shaft seal

-

600mm tread track

-

Strengthened side pedals

-

Bottom panels

Alarm system:

-

Controller failure

-

The pump pressure is abnormal

-

Abnormal pre-emptive pressure for each action

-

The power supply voltage is abnormal

-

Exception in the start-up motor relay

-

The hydraulic oil temperature is abnormal

-

Insufficient oil pressure and overheating of engine coolant

-

Insufficient amount of fuel.

-

Reverse oil filter block alarm

-

Engine fault alarm

-

Fuel filter water level alarm

-

Discrete water level alarm

Hydraulic system:

-

Select a switch for working mode

-

Control valve with primary overflow valve

-

Control valve band backup oil outlet

-

Oil absorption filter

-

Reverse oil filter

-

Leading Filter

-

Oil leak filter

Front-end working devices:

-

French sales

-

Shovel gap adjustment agency

-

Welding joints

-

Integrated lubrication system

-

All shovels are soldered with dust sealing rings

-

Strengthening the fully wrought box arms

-

Strengthening fully wrought box braces

-

Crash shields

The upper pivot platform:

-

Fuel Level Sensor

-

Hydraulic Oil Level Meter

-

toolbox

-

Reverse parking brake

-

Rearview mirror (right)

-

BACK VIEW camera

-

○ Cab warning light

Supervisory control system instrument:

-

GPS satellite positioning system

-

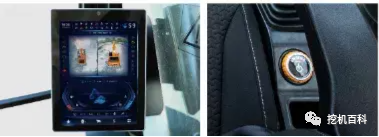

Color 10-inch display screen

-

The Iveco system

-

Hour meter, fuel level gage of fuel tank

-

Engine Coolant Temperature Table

-

It can increase altitude, track pressure, fuel consumption, etc.

Safety:

-

Emergency stop switch

-

Signal / alarm horn

-

rearview mirror

-

Back window emergency safe exit

-

Battery negative electrode switch

Others:

-

High-capacity electric bottle

-

Lockable ceiling cover

-

Lockable fuel filling cover

-

Anti-sliding pedals, handrails and sidewalks

-

Walking direction markers on the walking rack

-

Manual Butter Gun

A new look

1. Intelligent:

-

The 10-inch screen is once again upgraded to be thinner, brighter and sharper;

-

Higher system integration , body control and power management multi-integration , fewer parts ;

-

Support 4G network OTA upgrade , faster and safer , new one-click summon function ;

-

Delayed dimming of night stop lamps , one-key switch of front and back display , rear camera and other configurations to ensure driving safety .

2 . New air conditioning system :

-

With the new air conditioning system, the air duct is optimized, the cooling effect is stronger, and the air distribution is more reasonable。The air conditioner evaporator realizes the cleaning and maintenance of the car, and the cleaning is more simple.

3 . Appearance upgrade :

-

Sany has worked with a well-known automotive design company, and its exterior has been upgraded completely, with a steady and robust style.

-

Covered doors are highly designed, and side doors use a automotive double-layer door making process to strengthen.

-

The engine casing and toolbox lids are powered by air springs, making the opening process more labor-efficient.

4 . New interior :

-

The interior is fully upgraded , with narrow armrest box and minimal front control box , standard cup holder , 24V power outlet and USB interface , with car-level quality interior .

-

Equipped with comfortable shock-absorbing seats for enhanced vibration comfort .

5 . Structural upgrading :

-

Reinforced cab frame structure , optional ROPS cab .

-

The reliability of the opening and closing piece and the rubber strip is improved , making it more durable .

new technology

1. DPCTechnology:

-

The direct power control technology is used to dynamically adjust according to the load , so that all the commonly used working ranges can be moved to the economic zone , and the power matching can achieve " what you get is what you need , " thus reducing waste and realizing energy-saving .

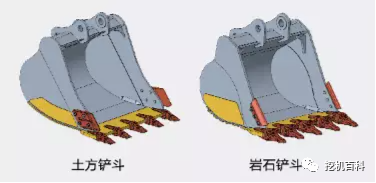

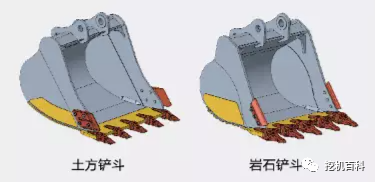

2 . Bucket Upgrades :

-

Standard earth bucket , optional rock bucket , achieve " one condition one bucket " to meet different working conditions .

-

Optimize the bucket shape, increase the flow of material penetration, reduce friction。The front blade plate and the support base plate increase the angle between the two, and increase the full bucket rate。The average resistance of the digging process is reduced, and the digging efficiency is increased.

3 . Bar upgrade :

-

The use of 2.9m short bucket rod, increase the secondary pressure function, digging force increased by more than 8%.

Repair and maintenance

-

The wide area covering is opened by means of daily maintenance and maintenance, and the repair is convenient and close to.

-

The standard filter block alarm and diesel pressure sensor are equipped to promptly alert customers to on-demand maintenance, enabling intelligent maintenance and maintenance.

-

The oil-water separator increases the water level alarm function, and when there is too much water in diesel, the alarm prompt is triggered, and maintenance is more stress-free.

-

The radiator has a dust net and can be removed from the side. There is a special safety net on the outside, and simply remove the safety net to clean the outer side of the dirt.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE