CAT 320GX Classic inheritance, brand new upgrade

CAT 320GX Classic inheritance, brand new upgrade

Medium-sized excavator

320GX

Summary

It's reliable. It's durable. Low cost. More would be gained.

The Cat 320GX combines reliability, high productivity and low cost.

-

Up to 15% lower fuel consumption

-

Up to 25 per cent benefits more

-

Built for everyday tasks

-

Up to 15 per cent reduction in CO2 emissions

Main technical specifications:

Power: 105.6kW

Machine weight: 19800 kg

Bucket capacity: 0.93 m3

Performance parameters, are being worked out. Stay tuned!

Configuration of the whole machine

Standard: ● Option: ○

Arm and pole:

●5.7 m(18'8" ) Stretch your arms

● 2.7 m (9 ') stretch rod

Driver's Room:

Noise-absorbing cab with a sticky plinth

● High resolution 203 mm (8" LCD touch screen monitor

● Mechanically adjusted seat with headrest

Automatic two-level air conditioning

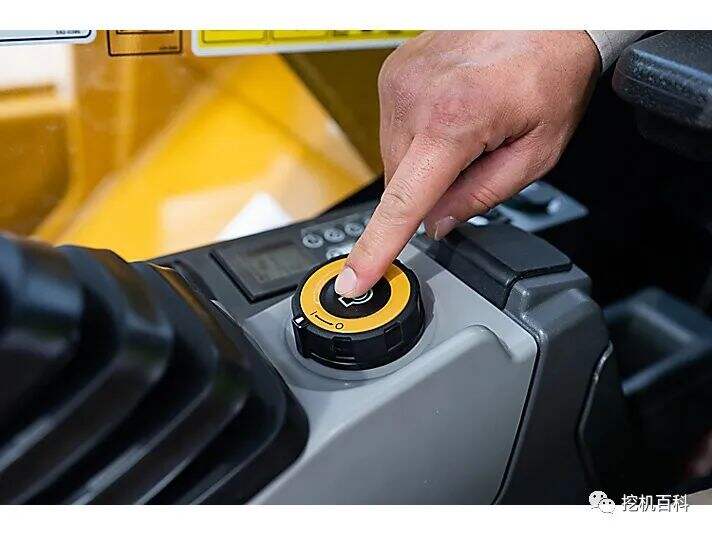

● Pressed starting engine control without a key

● Adjustable console mounted on the floor

● One-click manipulation grip

● AM / FM recorder with USB and auxiliary ports

● 24V DC socket

● Cupboard and Storage Room

70 / 30 steel windshield

● Upper radial wiper with a washer

● Openable steel hatch

● Top light

• Cleanable floor mats

○ Three-button manipulation grip

Electrical systems:

● Maintenance-free 950CCA battery (2 units)

● Electrical breaker switch

● LED chassis lights and driving room lights

● LED left arm light

○ LED right arm light

Powertrain:

Two optional modes: Power and Smart

Two optional modes: Power and Smart

● Working altitude up to 4500 m (14760 ft)

● 52 ° C (126 ° F) high temperature environment cooling capacity

● -25 ° C (-13 ° F) cold start capability

● Electric fuel injection pump

• Level 2 Fuel Filtration System

● Sealed double-filter air filter with integrated prefilter

Biodiesel with a maximum label of B20 can be used

Hydraulic system:

● Electronic main control valve, reserved hydraulically powered impact hammer mounting position

Serial electric pump

● Regenerative circuits for the arms and poles

Automatic hydraulic oil preheating

Automatic dual speed driving

Hydraulically powered impact hammer line

○ Hydraulically powered impact hammer pedal kit

○ Hydraulically powered impact hammer oil return filter

The chassis system and structure:

●600 mm(24" ) Three-clawed ground teeth track plate

● Grease to lubricate the track joint

Central track leading guard

● Bottom Protector

● Running motor shield

● Chain Points

●3600 kg(7940 lb)配重

Safety and protective devices:

● Anti-skateboard with buckles

• Handrails and handles

Lockable external toolbox / storage box

● rearview mirror kit

• Signal / alarm horn

● Hydraulic Locking Grip

○ BACK VIEW camera

○ FOGS with corresponding lighting

CAT Technology:

●Cat Product Link

Repair and maintenance:

● The filter is placed centrally

● Planned analysis of oil sample (SOS) sampler

Performance Overview

1. Performance reliable and durable:

-

The C4.4 engine and the electro-hydraulic pressure system can operate in sync, allowing you to move large quantities of material without consuming too much fuel.

-

The fast cycle time effectively improves productivity.

-

The new Cat ® General Load Excavator Bucket makes it easy to handle soft, wet and sticky materials.

-

Hydraulically powered impact hammer valve assembly is standard for increased versatility.

-

The arms, poles and shovel joints are reinforced to maximize durability.

-

Handle hot and cold weather with standard high ambient temperature capability at 52o C (125o F) and cold start capability at -25o C (-13o F).

-

The automatic hydraulic oil preheating function allows you to work faster in cold weather and helps extend the service life of your components.

-

Double fuel filtering prevents the engine from being affected by dirty diesel fuel.

-

Cat undercarriage is rugged and absorbs job site stress for improved performance and durability.

-

Sealed between the track solder and the liner by grease can reduce driving noise and prevent debris from entering, thereby extending the service life of the chassis system.

2. Reduce ownership and operating costs:

-

The C4.4 engine complies with China's fourth non-road emission standard; Compared to the 320 D2 GC used in similar applications, this digging machine can save up to 15% fuel consumption.

-

Offering both power and intelligence modes, the excavator is suitable for many types of operations. Power mode provides maximum output at all times. Smart mode automatically matches engine and hydraulic power with excavation conditions, resulting in fuel savings without affecting production.

-

Product Link™It is standard, so you can remotely monitor fuel consumption, machine health, location, and hours as needed via VisionLink ®.

3. It's easy to do:

-

The button starter engine is easy to operate.

-

A high-resolution 203mm (8in) touch screen monitor enables fast navigation.

-

The controlled devices at hand are all located in front of the operator, making it easy for the operator to control the excavator comfortably.

-

Use the operator ID to set power mode, joystick mode, and joystick response.

4. Working in comfort:

-

The driver's room is equipped with wide seats that can be flexibly adjusted to suit operators of all sizes.

-

Standard automatic thermostats ensure a comfortable temperature throughout the operation.

-

Convenient configurations such as a cassette player, headphone assist port and a USB port for connecting and charging the device; 24V DC socket can increase the charging speed of mobile phone.

-

There is a cupholder and storage space in front of the control device for large-capacity water cups and a widescreen mobile phone; The storage space behind the seat holds a large lunch box and other items.

5. Easy to maintain:

-

Daily maintenance can be carried out from the ground and maintenance costs can be reduced by 20% compared to the 320 D2 GC due to enhanced filter performance, extended service cycles and synchronization of service cycles. (The savings were calculated based on 12,000 machine hours.) )

-

The electric hydraulic system does not need lead pipes and filters to function properly.

-

The dust containing capacity of the new inlet filter is twice as much as that of the previous inlet filter.

-

The final drive and rotary drive oils allowed for an initial service life increase from 250 hours to 500 hours, a full twice increase.

-

All fuel filters are replaced synchronously every 1000 hours at twice the interval of the previous filters.

-

The new hydraulic oil filter provides better filtration performance, and the reverse drain valve keeps the oil clean when the filter is replaced at a time of up to 3,000 working hours, giving a longer service life - 50% longer than previous filter designs.

6. Higher security:

-

All the daily maintenance points are accessible from the ground, so there is no need to climb to the top of the excavator to check the filters or lubrication hooks.

-

Thanks to the smaller cockpit columns and wide window designs, operators have an excellent view, whether on the inner side of the ditch, in each direction of rotation or in the rear of the operator.

-

The optional rear view camera provides the operator with a better view.

-

The steps of the maintenance platform are equipped with anti-skateboards to help prevent slips.

-

The handrails meet the requirements of ISO 2867: 2011.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE