A Guide to the Use of Mining Equipment in Winter - Mining Mining Machinery

A Guide to the Use of Mining Equipment in Winter - Mining Mining Machinery

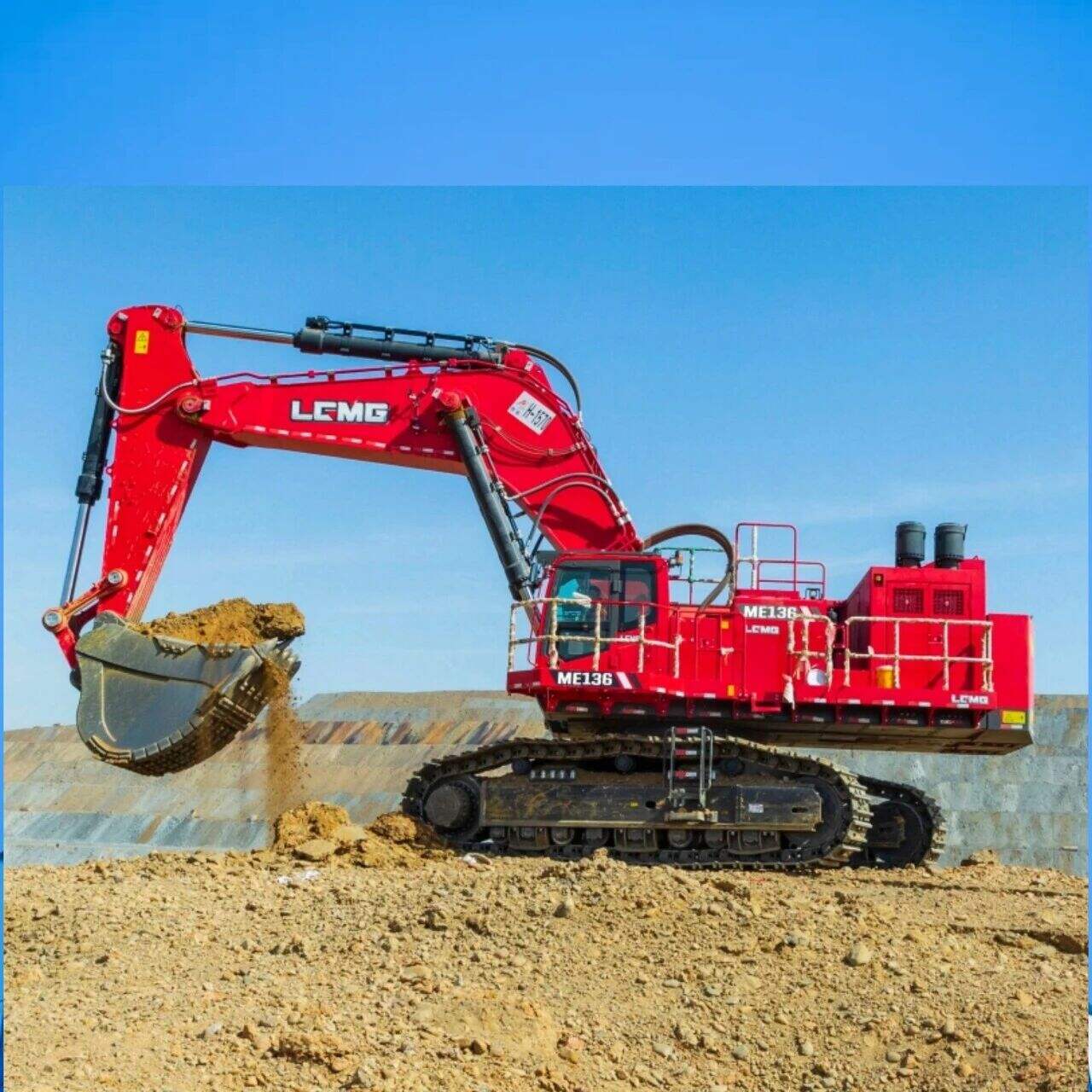

The cold winds are getting tighter and winter is coming! The construction heavy equipment reminds us that while we can keep ourselves warm, we must not forget the "old construction guy" - the excavator equipment that we have with us all year round.

Want to make the excavator operate steadily in the cold, not only to reduce faults and delay the work period, but also to extend the service life and ensure construction safety? Below, let me show you the key points of winter excavator maintenance, so that the equipment will not suffer during the winter and construction efficiency will not be reduced!

Selection of oils

1

Fuel Selection

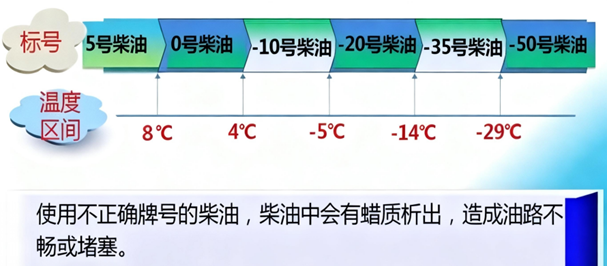

Core requirements: ensure fuel fluidity and avoid ice and impurities affecting combustion.

1. Select the diesel fuel rating according to ambient temperature; After the fuel switching, require the machine to operate at a minimum low speed for 5 minutes to ensure that the pipeline is fully filled with the newly added fuel.

2. Open the bottom of the fuel tank and the oil water separator drain valve every day to drain, and clean the fuel oil tank regularly.

2

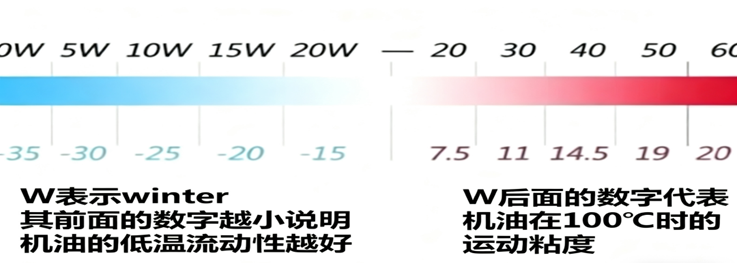

The choice of motor oil

Core requirements: The oil choice should take full account of the minimum winter temperature to ensure that the oil has good low-temperature fluidity, can quickly form an effective oil film inside the engine, reduce friction and wear, extend the engine life without increasing the operating resistance, and ensure the smooth operation of the engine.

1. To select the appropriate oil specification according to different seasons, different geographical areas and different ambient temperatures, see the oil choice comparison table in detail.

2. Phase III engine oil uses CI-4 and above oil.

(Note: The engine with post-treatment in stage IV must use CK-4 oil)

3

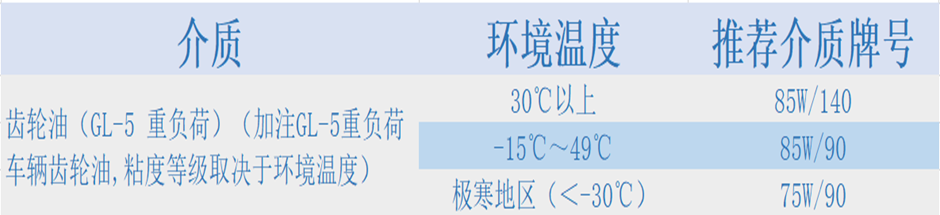

Selection of transmission gear oil

Core requirements: To ensure lubrication of the transmission system, resist low temperature adhesion, and prevent wear and tear of parts.

4

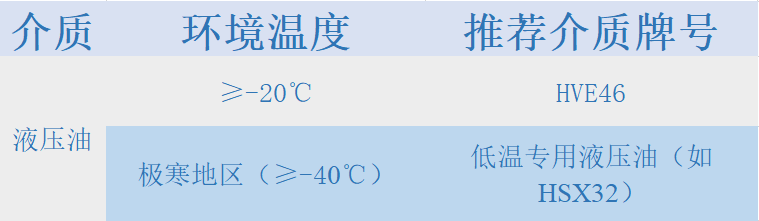

Selection of Hydraulic Oil

Core requirements: Maintain good fluidity at low temperatures, ensure hydraulic system responsiveness, and prevent pipeline blockage.

5

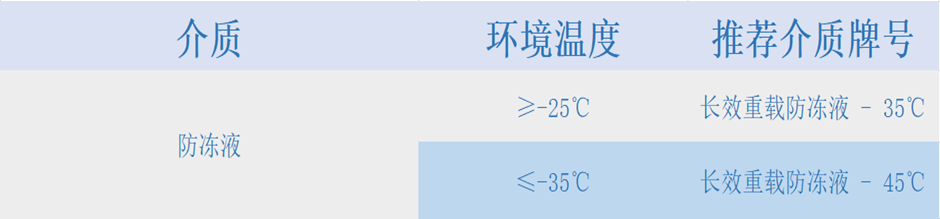

Selection and maintenance of antifreeze

Core requirements: prevent coolant from freezing and ensure heat dissipation.

Note:

1.Choose an antifreeze solution with a freezing point below the local minimum temperature of 10-15 ° C (e.g. local minimum - 10 ° C, choose a freezer point - 20 ~ -25 ° C product).

2. Different brands and different models of antifreeze must not be mixed to avoid chemical reactions, precipitation or the creation of bubbles.

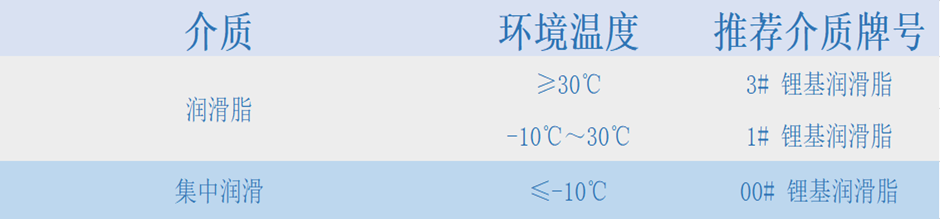

6

Selection of lubricants

Start the preheating process

1

When startup, the key remains in the startup position for no more than 20 seconds, and if startup fails, wait a few minutes and try again.

2

After successful start, run at low idle speed for 5 minutes, then increase the speed to 1200rpm.

3

Before the hydraulic system reaches the operating temperature, avoid manipulation of the equipment and prohibit violent operation.

4

If an abnormal noise, vibration or operational failure occurs during operation, stop immediately to check.

Attention during operation

1

All instrument data are monitored throughout the process, focusing on oil pressure, coolant temperature and hydraulic system status.

2

After successful start, run at low idle speed for 5 minutes, then increase the speed to 1200rpm. Avoid running at idle speed for a long time to prevent oil dilution from affecting the lubrication effect.

3

Keep the operation gapengine low speedoperation , to avoid frequent start and stop caused by component wear, at the same time should avoid engine idling for a long time .

4

Heating equipment is essential for outdoor work in winter, and the working condition of the heating equipment should be checked in advance.

Long-term parking needs protection

1

Cleaning equipment before parking, repairing paint finishes, treating leaking areas, and replacing worn parts.

2

Spray exposed accessories with anti-rust agents, apply grease to metal surfaces such as oil tanks, and complete the overall lubrication according to standard.

3

Fill the fuel tank and hydraulic oil tank to the maximum scale to reduce the condensation of water in the tank.

4

Confirm that the coolant freezing point is met and place the equipment on a flat, solid site that is free from the risk of ice slides.

5

When the ambient temperature is extremely low, disassemble the battery and store it at room temperature on a wood, plastic or rubber surface.

6

When parked outside, seal the exhaust pipe with a protective cover.

EN

EN

ONLINE

ONLINE