20 classic causes of failure common to Kubota excavators analysis and maintenance methods considerations do you know?

20 classic causes of failure common to Kubota excavators analysis and maintenance methods considerations do you know?

- Kubota excavator common20kinds of classic failure cause analysis and maintenance method notes ?

- Kubota20kinds of commonfailure causes analysis , solving methods and maintenance notes ?

1.Why is it difficult for Kubota excavators to start in winter? It is not only determined by its own technical condition, but also affected by the outside temperature. It is more difficult to start at low temperature in winter, mainly due to the following reasons:

- The winter climate is cold, the ambient temperature is low, the viscosity of the engine oil increases, and the frictional resistance of various moving parts increases, which reduces the starting speed and is difficult to start.

- The capacity of the battery decreases with the decrease of temperature, which further reduces the starting speed.

- Due to the decrease in starting speed, the leakage of compressed air increases, and the heat dissipation of the cylinder wall increases, resulting in a great decrease in the temperature and pressure of the air at the end of compression, which increases the delay period of diesel ignition and even cannot be burned in severe cases.

- The viscosity of diesel at low temperature increases, which reduces the injection speed, and the swirl speed, temperature and pressure of the air at the end of compression are relatively low, so that the atomization quality of diesel injected into the cylinder is poor, and it is difficult to quickly form a good combustible gas with the air and ignite and burn in time, or even cannot catch fire, resulting in difficulty in starting.

2.What are the conditions for good starting performance of Kubota excavators?

- There must be enough starting speed. The starting speed is high, the gas leakage in the cylinder is small, the heat transfer time of compressed air to the cylinder wall is short, and the heat loss is less, so that the gas temperature and pressure at the end of compression can be improved. Generally, the rotation speed is required to be above 100r/min.

- The sealing of the cylinder should be good. This can further reduce the amount of air leakage, ensure that the gas has sufficient combustion temperature and pressure at the end of compression, and the compression pressure of the cylinder should not be less than 80% of the standard value.

- The mating gap between the excavator and the running parts is required to be appropriate and well lubricated.

- The battery should have sufficient starting capacity, and the technical condition of the starting circuit should be normal.

- The amount of starting oil meets the regulations, the injection quality is good, and the injection advance angle should meet the requirements.

- Use fuel that meets the requirements

3.When the Kubota excavator starts, the mechanical fault diagnosis and repair of the crankshaft cannot rotate When the excavator starts, when the starting system is intact, press the starter switch, the starter makes a sound and the crankshaft cannot rotate, which is a mechanical failure. The reasons that cause the excavator crankshaft not to turn are described below.

(1) The starter and flywheel teeth are poorly meshed. The ring collides with the starter gear when starting the excavator, causing tooth damage or one-sided tooth wear. If the teeth are damaged or worn more than three times in a row, it will be difficult for the starter gear to engage with the ring teeth.

(2) Adhesive cylinder. When the temperature of the excavator is too high, the engine is stopped and turned off, and the heat is difficult to dissipate, and the piston ring and cylinder at high temperature are stuck to the cylinder and cannot be started after cooling.

(3) The crankshaft is locked. Due to the failure of the lubrication system or lack of oil, the dry friction of the plain bearing caused the crankshaft to eventually lock up and cannot start.

(4) The plunger of the fuel injection pump is jammed.

4.Diagnosis that the Kubota excavator can turn when starting, but cannot start (there is no smoke in the exhaust pipe). When starting the excavator, there is no smoke discharge from the exhaust pipe, and there is no explosion sound, which is generally an oil circuit problem, and the detailed analysis is as follows:

(1) There is no oil in the fuel tank.

(2) The fuel filter and oil-water separator are blocked.

(3) The low-pressure oil circuit does not supply oil.

(4) The oil injection pump does not pump oil.

(5) There is air in the oil circuit.

(6) The phase of gas distribution is inaccurate. The moment of opening of the valve is not coordinated with the stroke of the piston in the cylinder. For example, when the piston is in the cylinder for compression stroke, the intake and exhaust valves are open, and the fresh air is driven out of the cylinder, so that there is no combustion gas in the cylinder and cannot start.

(7) The solenoid valve of the fuel injection pump is broken and closed, and the diesel cannot enter the high-pressure chamber.

5.Diagnosis of Kubota excavator difficulty or inability to start, exhaust pipe discharge a large amount of white smoke. The reasons for the large amount of white smoke emitted from the exhaust pipe when the excavator starts are as follows:

(1) There is water in the diesel, and the water evaporates into water vapor in the cylinder and is discharged from the exhaust pipe.

(2) The cylinder head bolt is loose or the cylinder gasket is broken, allowing cooling water to enter the cylinder.

(3) There is a trachoma or crack somewhere in the cylinder block or cylinder head, and the water enters the cylinder and evaporates and expels.

6.Diagnosis of Kubota excavator difficulty or inability to start, and a large amount of gray and white smoke coming from the exhaust pipe. The excavator is difficult to start, and a large amount of gray and white smoke is discharged from the exhaust pipe as diesel vapor.

(1) The temperature of the excavator is too low, and the diesel is not easy to evaporate and burn.

(2) Poor atomization of the fuel injector

(3) The oil supply time is too late.

(4) The oil supply is too small and the mixture is too thin.

(5) The cylinder leaks too much air, and the ignition temperature cannot be reached after compression.

7.Kubota excavator is difficult to start or cannot start, exhaust pipeDiagnosis of a large amount of black smoke. The difficulty of starting the excavator and the large amount of black smoke emitted from the exhaust pipe are the result of incomplete diesel combustion

(1) poor diesel quality

(2) poor air intake and clogged air filter.

(3) The fuel injection timing is adjusted too early.

(4) The sealing of the injector needle valve is poor, and there is a phenomenon of dripping oil.

(5) The injection pressure is too low.

(6) The oil supply of the fuel injection pump is too large, and the combustion deteriorates.

(7) The cylinder pressure is low and the atomization is poor.

8.Diagnosis of Kubota excavator hot start difficulty The excavator has a good cold start, but after a period of operation, the temperature rises and then stalls, and it is difficult to start again, mainly due to the serious wear of the injection pump plunger pair and the injector needle valve pair. When the hot car starts, due to the high temperature of the fuel injection pump and fuel filter, the fuel viscosity decreases, and the starting speed is low, most of the diesel leaks from the worn gaps, resulting in insufficient starting oil and cannot start.

9.Diagnosis and treatment of Kubota excavator with normal low speed and short-term high speed, and too little smoke exhaust. The excavator idle speed is good, and the throttle speed can be quickly increased, but the continuous throttle speed is not easy to increase, and the driving is weak, or the use of medium speed or above gear cannot be driven, which is caused by insufficient low-pressure oil supply.

(1) The diesel filter or oil-water separator is blocked.

(2) The low-pressure oil circuit is not smooth.

(3) The oil supply of the oil pump is insufficient or the oil inlet filter is blocked.

(4) The fuel cap inlet valve fails. All of the above situations can cause the fuel pressure of the low-pressure oil cavity of the fuel injection pump to be insufficient, which can only maintain the oil supply required for small loads. When large and medium loads require more fuel supply, they cannot be satisfied, resulting in weak driving.

10.The diagnosis of Kubota excavator is normal at low speed but not at high speed, and the smoke exhaust is too small. The low speed of the excavator is good, but the speed can not be increased when accelerating, and the driving is weak, which is caused by insufficient circulating oil supply.

(1) The fuel injection pump is improperly adjusted, which reduces the oil supply.

(2) The elasticity of the governor spring is reduced due to fatigue. When the throttle is stepped to the end, the oil volume adjustment tie rod cannot be moved forward to the head, resulting in a decrease in the oil supply of the fuel injection pump and the excavator cannot reach the rated speed

(3) The plunger and sleeve of the fuel injection pump, the injector needle valve and the needle valve body are seriously worn, which increases the leakage of diesel during the pump and the oil supply is relatively reduced.

(4) Improper adjustment of the accelerator control lever, or the accelerator pedal pin is too open, so that the accelerator pedal cannot be in place, resulting in too little fuel supply at full load.

(5) There is air in the oil circuit.

11.The fault diagnosis and analysis of Kubota excavator power is insufficient and the gray and white smoke discharge is as follows: The excavator is insufficient and the exhaust pipe exhausts gray and white smoke, which is generally caused by the late oil injection time. At this time, not only is the high-speed operation poor, the acceleration is not sensitive, but the temperature is easy to be too high.

(1) The fuel injection advance angle is too small.

(2) Poor atomization of the fuel injector.

(3) The temperature of the excavator is too low.

(4) There is water in the cylinder.

(5) There is water in diesel

12.Analysis of the fault causes of Kubota excavator's insufficient power and thick black smoke: there are two phenomena of insufficient power of the excavator, uneven speed, and exhaust pipe exhaust thick black smoke: one is continuous black smoke; the other is intermittent black smoke and the excavator shakes. The excavator's insufficient power and continuous black smoke are formed by the excessive oil supply of most or all cylinders of the excavator, the imbalance of fuel and air mixing, the serious lack of oxygen during combustion, the incomplete combustion of diesel, and the suspended free carbon elements are discharged with the exhaust gas. If the exhaust pipe is intermittent black smoke and accompanied by a "popping" sound, it means that the individual cylinder is not burned completely. The reasons are summarized as follows:

(1) Improper debugging of the fuel injection pump, resulting in excessive oil supply and incomplete combustion.

(2) The injection quality of most injectors is poor.

(3) When the oil supply is not correct.

(4) The opening height of the intake valve is reduced and the opening time is delayed, resulting in insufficient air intake.

(5) The air filter element is too dirty or the air filter is installed incorrectly, making the air not smooth.

(6) The supercharging efficiency of the supercharger decreases.

(7) Poor fuel quality.

13.Diagnosis and treatment of Kubota excavator insufficient power and blue smoke discharge. The excavator emits blue smoke at low temperature or low load, and after the temperature rises, it becomes dark gray smoke, and the power is insufficient.

(1) Poor air intake, resulting in the oil in the supercharger being sucked into the cylinder for combustion.

(2) There is too much oil in the oil pan, and the oil exceeds the maximum limit.

(3) Valve guide inlet oil.

(4) The cylinder is seriously diverted oil。

(5) The rotor shaft of the supercharger is seriously worn, and the oil ring is damaged, causing the supercharger to fail to reach the rated speed and leak oil

14.Why is the supercharger the most faulty assembly on an excavator? Because the rated working speed of the supercharger is more than 130,000 revolutions per minute, and at the outlet of the exhaust manifold, the temperature is extremely high (above 800 °C), and the inlet and exhaust pressure is also large, that is, high temperature, high pressure, high speed, so the requirements for lubrication, cooling and sealing of the supercharger are relatively high. In order to ensure the service life of the supercharger, the design should ensure the lubrication and cooling of the floating bearing of the supercharger, and at the same time, it is required to do the following:

(1) The excavator should be idled for 3-5 minutes after starting, and the load should not be increased immediately to ensure the good lubrication of the supercharger. The main reason is that the supercharger is located on the top of the excavator, if the supercharger starts to run at high speed immediately after the excavator starts, it will cause the oil pressure to fail to rise in time to supply oil to the supercharger, resulting in oil shortage damage to the supercharger, and even burning out the entire supercharger.

(2) The idle time should not be too long, generally no more than 10 minutes, and too long idle time can easily cause oil leakage at the compressor end.

(3) Do not turn off the excavator immediately before stopping, and idle for 3-5 minutes to reduce the speed of the supercharger and the temperature of the exhaust system to prevent failures such as heat recovery, oil coking, bearing burnout, etc. Regular and incorrect use can damage the supercharger.

(4) Excavators that have not been used for a long time (generally more than 7 days), or excavators that have been replaced with new superchargers, should be filled with oil at the oil inlet of the supercharger before use, otherwise the life will be reduced or the supercharger will be damaged due to poor lubrication.

(5) Regularly check whether there is loose air leakage/oil leakage at each connection part, whether the oil return pipe is unobstructed, and if so, it should be eliminated in time.

(6) Ensure that the air filter is clean and replaced regularly as required.

(7) Change the oil/oil filter regularly.

(8) Regularly check the radial axial clearance of the supercharger shaft, the axial clearance should not be greater than 0.15 mm, and the radial clearance is: the gap between the impeller and the pressing shell is not less than 0.10 mm, otherwise it should be repaired by professionals to avoid expanding losses.

15.Why is the life of the new supercharger often short after the supercharger on some excavators is damaged?

(1) The lubricating oil is not clean.

(2) There are impurities in the oil channel.

(3) There is a foreign object in the intake and exhaust pipeline

16.Analysis and fault handling of the causes of Kubota excavator no idle: the excavator has no idle, which is generally manifested as the throttle is placed in the idle position and stalls, when the throttle is slightly increased, the speed rises quickly, and it cannot run stably at low speed

(1) The idle spring of the governor is too soft or broken.

(2) The sensor element of the governor is too worn.

(3) The plunger of the oil injection pump is seriously worn.

(4) The temperature is too low.

(5) The cylinder pressure is too low

17.Analysis and troubleshooting of the cause of Kubota's high idle speed: The excavator's idle speed is too high, which is manifested as the excavator speed is still higher than the idle speed limit when the throttle is lifted.

(1) Improper adjustment of the throttle control rod.

(2) The throttle return spring is too soft.

(3) Idle speed limit stop block or adjustment screw is out of balance.

(4) The idle spring is too hard or the preload is adjusted too much

18.Analysis and fault diagnosis of Kubota's idle speed: The manifestation of excavator idle instability is that when idling at idle, it is fast and slow, or there is vibration, which makes the machine stall when decelerating or shifting gears. The detailed cause analysis is as follows:

(1) There is air in the oil circuit.

(2) The oil supply of low-pressure oil circuit is not smooth.

(3) Improper adjustment of the idle stabilizer device.

(4) Poor atomization of the fuel injector.

(5) The oil supply of the oil injection pump is uneven.

(6) The pins and fork heads of the connecting members of the governor are too worn

19.Analysis of the reasons for the sudden stalling of the Kubota excavator? The sudden stalling of the excavator during operation refers to the phenomenon that the excavator is not released when the throttle is not released, and the engine cannot be started again after the engine is turned off. This phenomenon is generally caused by mechanical failure, and the reasons are as follows:

(1) The drive gear of the fuel injection pump is broken and the transmission gear is faulty.

(2) The shaft of the fuel injection pump is broken.

(3) The internal moving parts of the excavator are stuck.

(4) The oil injection pump controls the tie rod and connecting pin to fall off

20.Analysis of the causes of slow stalling of Kubota excavator: The excavator slowly stalls without releasing the throttle, which is generally caused by untimely oil supply or interruption of oil supply. It is manifested in the gradual weakness of the excavator during operation, and finally automatically shuts down.

(1) The diesel fuel in the tank is exhausted.

(2) The ventilation valve of the fuel tank cap is blocked.

(3) The fuel filter or oil-water separator is blocked.

(4) The oil supply pipeline is broken or more air is infiltrate.

(5) The oil pump is not working.

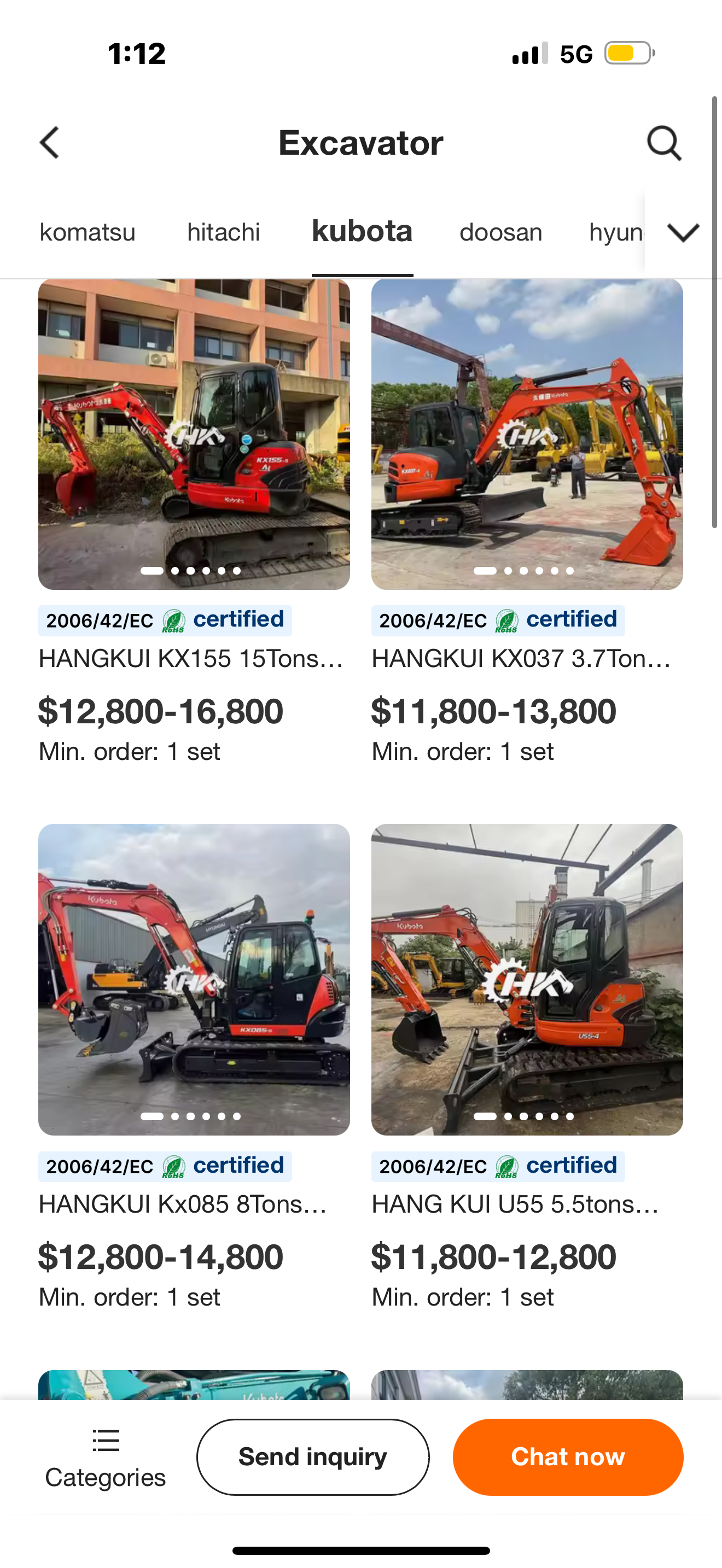

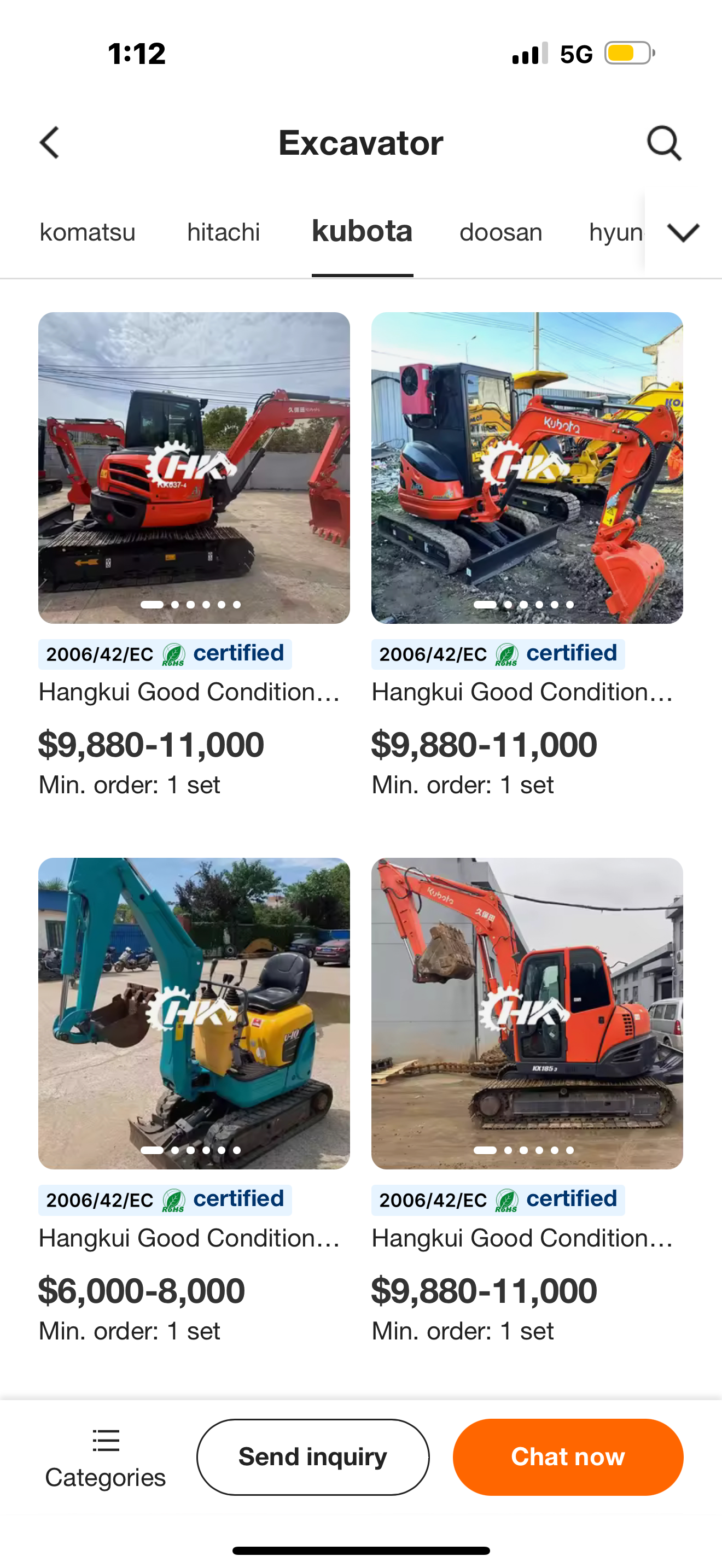

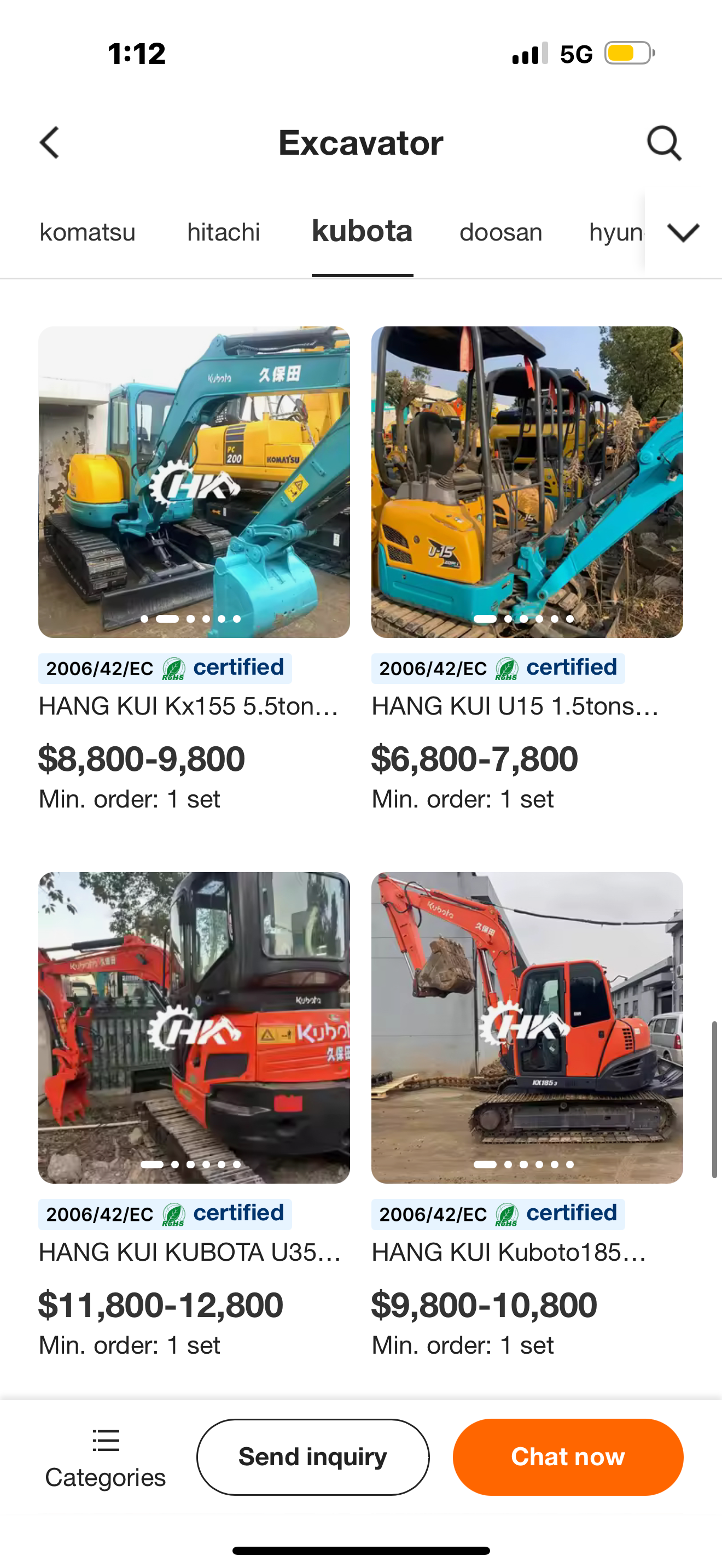

(6)If there is water in the tank, if there is any problem with the Kubota excavator high-temperature cylinder and Kubota excavator maintenance, consultation, information, technical support, experience sharing, communication, after-sales service, technical support can be #Shanghai Hangkui Construction Machinery Co., Ltd. # for communication, exchange, thank you.

EN

EN

ONLINE

ONLINE