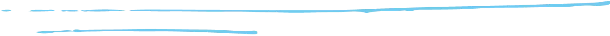

Trashëgimi klasike CAT 374, përmirësim i ri plotësisht

Trashëgimi klasike CAT 374, përmirësim i ri plotësisht

Ekskavatori shumë i madh

374

-

rritje 10% në momentin e torkut

-

Deri në 2 herë qëndrueshmëri strukturore më e madhe

-

Deri në 20% reduktim i kostove të mirëmbajtjes

Parametra konfigurimi

Standard: ● Opsion: x Për t'u përsosur: / Vlerë referimi: *

1. Parametrat e performancës:

|

forcë |

Forca maksimale e tërheqjes |

/ |

kN·m |

|

Forca e Hapjes së Kovës - ISO |

405 |

kN |

|

|

Forca e Hapjes së Gjymtyrës së Kovës - ISO |

352 |

kN |

|

|

Trançori rotacion |

247 |

kN·m |

|

|

shpejtësi |

Shpejtësia e kundërt |

6.5 |

r/min |

|

lëvizje në shpejtësi të lartë/të ulët |

/ |

km/h |

|

|

zë |

Presioni i zërit të operatorit (ISO 6396:2008) |

/ |

db (A) |

|

Presioni mesatar i zërit nga jashtë (ISO 6395:2008) |

/ |

db (A) |

|

|

Tjetër |

Aftësia për tu ngjitur në rruge të pjerrëta |

/ |

grad |

|

Tokësia është më e lartë se presioni |

/ |

kPA |

2. Sistemi i transmisionit:

|

Modeli i motorit |

Cat C15 |

|

|

Larg Power |

361 |

kW |

|

vëllimi i çarkullimit |

15.2 |

L |

|

Standardet e emisioneve |

Vendi 4 |

|

|

Shtigjet e emisioneve |

DPF (ure) |

3. Sistemi hidraulik - i kontrolluar plotësisht elektrikisht:

|

Stresi: |

||

|

Shtypja maksimale - pajisje |

37000 |

kPA |

|

Tensioni maksimal - Mënyra e përmirësimit |

38000 |

kPA |

|

Stresi i punës - lëvizja |

35000 |

kPA |

|

Stresi në punë - kthimi |

35000 |

kPA |

|

Qarkullim: |

||

|

Sistemi kryesor - pajisje |

896 |

L/min |

|

Sistem i kundërt |

/ |

L/min |

|

Rezervuar karburanti: |

||

|

Cilindri i armatosur: gjatësia e cilindrit - kursi |

/ |

mm |

|

Cilindri i grumbullit: gjatësia e cilindrit - kursi |

/ |

mm |

|

Rezervuari i vajit të spateles: gjatësia e cilindrit - kursi |

/ |

mm |

4. Aplikacioni punues:

|

Lëvizni krahët tuaj |

7000 |

mm |

|

Klube standarde |

3000 |

mm |

|

Kopështi i luftës duket |

5 |

m³ |

5. Sistemi i rameve:

|

Gjerësia e panelit të gjurmës |

650 |

mm |

|

Numri i pajisjeve me tread - një anë |

/ |

pjesë |

|

Numri i rrotave mbështetëse - një anë |

/ |

individuale |

|

Rota e llambës - një anë |

3 |

individuale |

|

Pesha e peshës |

/ |

kg |

6. Sasia e vajit dhe ujit të shtuar:

|

Depo Larg |

920 |

L |

|

Sistemi hidraulik |

620 |

L |

|

Rezervuari hidraulik i karburantit |

326 |

L |

|

Oli i Motrorit |

62 |

L |

|

Sistemi i Larg |

71 |

L |

|

Marshi i kundërt |

20 |

L |

|

Pajisjet më të fundit (çdo njëri) |

32 |

L |

|

DEF箱 |

80 |

L |

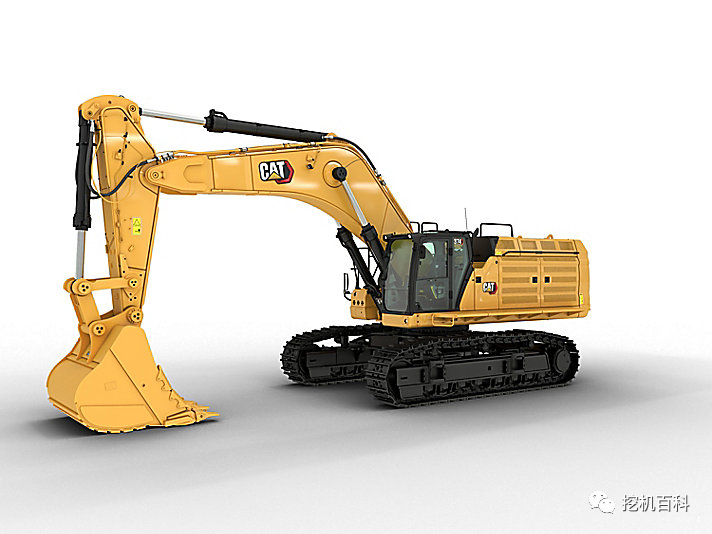

7. Faktor forma (fotografi referuese):

|

1. |

Lartësia e mbështetësit të dorës |

3982 |

mm |

|

Lartësia e kabinës në krye |

3559 |

mm |

|

|

Lartësia totale (gjatë transportit) |

/ |

mm |

|

|

2. |

Gjatësia e transportit |

12978 |

mm |

|

3. |

Lartësia e raftit të sipërm |

/ |

mm |

|

4. |

Rrezja e boshtit të pasmë |

4171 |

mm |

|

5. |

Zbrazëtia e peshës |

1494 |

mm |

|

6. |

Hapësirat midis nivelit të tokës |

782 |

mm |

|

7. |

Distanca midis qendrave të pajisjeve rënduese të rënda |

4705 |

mm |

|

8. |

Gjatësia e shtegut |

5873 |

mm |

|

9. |

Gjatësia e gjurmës (e zgjatshme) |

2750/3410 |

mm |

|

10. |

Gjerësia e transportit të shasisë |

3400 |

mm |

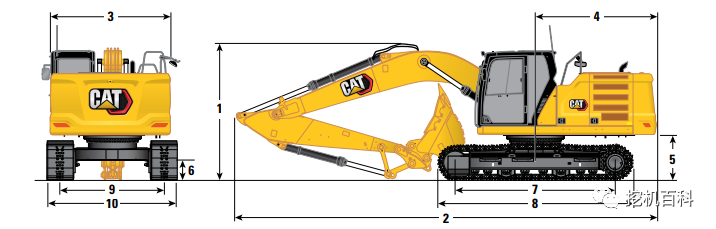

8. Domeni i punës (imazh referencë):

|

1. |

Thellësia maksimale e ekskavimit |

7240 |

mm |

|

2. |

Distanca maksimale e përhapjes nga toka |

11470 |

mm |

|

3. |

Lartësia maksimale e minierës |

11000 |

mm |

|

4. |

Larg dhe vorte ngarkimi maksimale |

7050 |

mm |

|

5. |

Lartësia minimale e ngarkesës |

3470 |

mm |

|

6. |

thellësia maksimale e shpalosjes 2440 mm |

7080 |

mm |

|

7. |

Thellësia maksimale vertikale e shpalosjes |

3710 |

mm |

Konfigurimi funksional

Standard: ● Opsion: ○

1 . Kabina e shoferit :

|

Standard |

Përshtaten |

|

|

Monitor me ekran LCD prekje me rezolucion të lartë 203 mm (8") |

● |

|

|

Ulese me sospension ajri të rregullueshëm dhe të ngrohur (ekskluzive për kabinat luksoze) |

● |

|

|

Monitor me ekran LCD prekës me rezolucion të lartë 254 mm (10") |

○ |

|

|

Rele të asistuara |

○ |

2. Teknologjia CAT:

|

Standard |

Përshtaten |

|

|

Lidhja e Produktit Cat |

● |

|

|

Aftësi të largësisë për shërbime |

● |

3. Sistemet elektrike:

|

Standard |

Përshtaten |

|

|

Bateri 1400CCA pa mirëmbajtje (2) |

● |

|

|

Çelës qendror i ndërprerjes së energjisë elektrike |

● |

|

|

Dritat e bastimentit |

● |

|

|

Drita LED të trurit dhe të kabinit të drejtimit |

○ |

4. Motori:

|

Standard |

Përshtaten |

|

|

Tre mënyra të fuqisë oporonuese: Fuqi, Smart dhe Ekonomik në karburant |

● |

|

|

Rregullim automatik i shpejtësisë së motorrit |

● |

|

|

Lartësi e punës deri në 4500 m (14760 ft) |

● |

|

|

kapacitet ftohjeje ambientale me temperaturë të lartë 52 °C (126 °F) |

● |

|

|

aftësi nisjeje në kushte të ftohtë -18 °C (-0.4 °F) |

● |

|

|

Hidraulikisht i aftë për të rrotulluar ventilatorin |

● |

|

|

Filter ajri me dy bërthama me prefilter të integruar |

● |

|

|

Çaktivizo në distancë |

● |

|

|

Ngrohës cilindri për nisje të ftohtë |

○ |

5. Sistemi hidraulik:

|

Standard |

Përshtaten |

|

|

Qarku i rikthimit të krahëve dhe polusit |

● |

|

|

Valvulë elektronike kryesore kontrolli |

● |

|

|

Unazë e mbyllur e specializuar me rryme të kundërt |

● |

|

|

Modalitet ngarkese të rënda për përmirësim |

● |

|

|

Ngrohje paraprake automatike e vajit hidraulik |

● |

|

|

Fren automatik parkimi me marsh të kundërt |

● |

|

|

Filtër i performancës së lartë për rekuperim të vajit hidraulik |

● |

|

|

Punon në dy shpejtësi |

● |

|

|

Mund të përdorë vaj hidraulik biologjik |

● |

|

|

Kontrolli i veglave |

○ |

6. Mjete sigurie dhe mbrojtëse:

|

Standard |

Përshtaten |

|

|

Sistemi i Sigurisë Caterpillar One Key |

● |

|

|

Kutia e jashtme e mjetave / kuti ruajtjeje me çelës |

● |

|

|

Derë me çelës, enë djegie dhe kapakë të rezervuarit hidraulik me çelës |

● |

|

|

Platformë mirëmbajtjeje e pajisur me bulona të braktisur dhe kundër patinazhit |

● |

|

|

Balustrada dhe dërrasa të djathta |

● |

|

|

Paketë pasqyre prapa |

● |

|

|

Sinjal / brumë alarmi |

● |

|

|

Ç'aktivizues motorik me ndihmë tokëse |

● |

|

|

pamje 360 ° |

○ |

|

|

Kamerë e larg dhe larg |

○ |

|

|

Alarm kthimi |

○ |

|

|

Drita e detektimit |

○ |

7. Riparimi dhe mirëmbajtja:

|

Standard |

Përshtaten |

|

|

I lehtë për t'u instaluar një sistem vetëlubrifikimi në çdo kohë |

● |

|

|

Rregullimi i grupit të filtrit të vajit të lubrifikimit dhe të filtrit të karburantit |

● |

|

|

Porti i mostrimit për analizë të planifikuar të mostrës së vajit (SOS) |

● |

8. Sistemi dhe struktura e askesës:

|

Standard |

Përshtaten |

|

|

Sistem i zgjatur me gjatësi variabël rruge |

● |

|

|

Unazat e traksionit në askes |

● |

|

|

Peshimi Standard |

● |

|

|

650 mm (26") Ngarkesë e rëndë, pllakë me gjembë të dyfishtë për terren të butë |

○ |

9. Krah dhe shufër:

|

Standard |

Përshtaten |

|

|

7,0 m (23') Shovel me krah të madh |

○ |

|

|

2,57 m (8'5") krah i gjatë për shovel |

○ |

|

|

3,0 m (9'10") krah për shovel me kapacitet të madh |

○ |

Përmbledhje Performancesh

1. Performancë e lartë:

-

3 74 Mund të ngarkojë deri në 33 kamiona me një kapacitet ngarkese prej 36 tonë metrike (40 tonë amerikane) në orë.

-

Momenti i rrotullimit është rritur me 10% dhe koha e ciklit është më e shkurtër krahasuar me serinë e mëparshme.

-

Cikli i ri statik hidraulik i kthimit e bën operacionet multifunksionale më të rrjedhshme dhe efikase.

-

Mënyra e përmirësuar e ngritjes së ngarkesës rris shtypjen e sistemit dhe ju ndihmon të ngrini dhe vendosni materiale të rënda me lehtësi.

-

Krahet, polat dhe raftet janë dy herë më të qëndrueshëm sesa seria e mëparshme, duke ofruar performancë të besueshme për vite në ambientet më të rënda.

-

I disponueshëm në tre mënyra të funksionimit, ekskavatori është i përshtatshëm për një varietet llojesh punë: i fuqishëm, inteligjent dhe ekonomik në harxhimin e karburantit.

-

Dentët e spateve Advansys™ përmirësojnë aftësinë e penetrimit dhe zvogëlojnë kohën e ciklit. Një çelës i thjeshtë i bulonave, në vend të një malli me goditje hidraulike ose një mjet special, mund të përdoret për të ndryshuar shpejt majat, duke përmirësuar sigurinë dhe zgjatur kohën e punës.

-

Opsionet hidraulike ndihmëse ju japin fleksibilitetin që keni nevojë për të përdorur një gamë të gjerë pajisjesh Cat.

-

Ideal për sfida temperaturash dhe mbrojtje të punës suaj normale. Ekskavatori ka aftësi funksionimi në temperaturë të lartë prej 52 °C (125 °F) dhe aftësi standarde nisjeje në kushte të ftohtë prej -18 °C (-0,4 °F).

2. Rritja e efikasitetit dhe produktivitetit me teknologjinë Cat:

-

Ekuipim standard. Produkt Lokacioni i makinës, orët e punës së makinës, konsumi i karburantit, produktiviteti, koha e qëndrimit në gjendje të pandërprerë, kodet diagnostikore dhe të dhënat e tjera të makinës mund të sigurohen përmes ndërfaqes online VisionLink për t'ju ndihmuar të përmirësoni efikasitetin në zyrë dhe të reduktoni kostot e funksionimit.

-

Mund të përdorni veçorinë e diagnozës së largët për të kontaktuar specialistët e shërbimit në çdo kohë, për t'ju ndihmuar të zgjidhni problemet dhe të ktheheni shpejt në punë.

-

Funksioni i rifreskimit të largët funksionon siç është planifikuar, duke siguruar që softueri i makinës të mbetet i azhornuar, duke optimizuar kështu performancën.

3. Është e lehtë për t'u bërë:

-

Motori mund të niset me buton, kartë kyçe Bluetooth ose me funksionin unik iD e operatorit.

-

Çdo buton i joystick-it programohet duke përdorur ID-në e operatorit, dhe elementet e programueshme përfshijnë modin e energjisë, reagimin dhe modin e kontrollit; Makina kujton këto cilësime dhe i thërret sa herë që e nisni punën me të.

-

Funksioni automatik i parinxehjes së vajit hidraulik ju lejon të punoni më shpejt në kushte të ftohta dhe ndihmon në zgjatimin e jetës së komponentëve tuaj.

-

Monitorë me ekran prekjeje standard me rezolucion të lartë 254 mm (10 in) ose kontroll me çelës lejojnë navigim të shpejtë.

-

Nuk e dini se si funksionon një funksion i caktuar apo si mirëmbahet një ekskavator? Manuali i operatorit është i përdorshëm në çdo kohë me një prekje të gishtit në ekranin touch.

-

Dallga e vetme Cat e bën më të lehtë kontrollin e lëvizjes së makinës për heqje. Me shtypjen e një butoni, ju mund të kontrolloni lëvizjen dhe timonin me një dorë, pa u dashur të përdorni të dy dorekat për levën e timonit ose të dy këmbët mbi pedalin.

-

Keni nevojë për më shumë motivim gjatë punës? Duke aktivizuar ngarkesën automatike të rritjes, ju merrni saktësisht 8% më shumë fuqi kur kjo ju duhet.

4 . Punoni me këndejshmëri në një kabine të re të plotë:

-

Është e pajisur me kontroll automatik temperaturë dhe vende me ngrohje. Mund të funksionojë gjatë gjithë vitit.

-

Me konsolën e majtë që ngrihet, ju mund të hyjni dhe dalni nga kabina më lehtë.

-

Baza e fortë e avancuar zvogëlon vibracionet në kabine deri në 50 përqind në krahasim me modelet e mëparshme të ekskavatorëve.

-

Pajisjet e kontrolluara janë të vendosura përpara operatorit, gjë që e bën të lehtë për operatorin të kontrollojë dredhësin me rehati.

-

Ka shumë hapësirë parkimi nën dhe pas ulëseve, mbi krye dhe në dhomën e kontrollit për të ruajtur lehtësisht pajisjet tuaja.

-

Lidhni pajisjet personale dhe bëni thirrje pa duar lehtë me një port USB të zakonshëm pa telash dhe teknologjinë Bluetooth ®.

5. Ngarkesë më e ulët mirëmbajtjeje:

-

Për shkak të kapacitet i reduktuar i vajit hidraulik dhe intervale mirëmbajtjeje më të gjata dhe të sinkronizuara, pritet që kostoja e mirëmbajtjes të jetë deri 20% më e ulët sesa te 374F

-

Ekskavatori ka një pikë instalimi të integruar, e cila e bën të lehtë shtimin e një sistemi automatik lubrifikimi në çdo kohë. Kiti i modifikimit për lubrifikim automatik, i cili është i pajisur, ofron fiksues shtesë për montimin e pompave lubrifikuese dhe mbrojtësve të tubave.

-

Jeta e filtrit dhe cikli i mirëmbajtjes së ekskavatorit mund të gjurmohen përmes një monitori në dhomën e vozitjes.

-

Zëvendësoni filtër karburanti në mënyrë të sinkronizuar çdo 1000 orë; Zëvendësimi mund të kryhet nga platforma e sipërme.

-

Aftësia e filtrit të ri hyrës për grackë është dy herë më e madhe sesa ajo e filtrit të vjetër hyrës.

-

Filtri i ri i vajit hidraulik ofron performancë më të mirë filtrimi, dhe valvula e kthimit të vajit e mbart vajin të pastër kur filtri zëvendësohet në një kohë prej 3.000 orësh pune, duke i dhënë një jetë shërbimi më të gjatë - 50% më të gjatë sesa dizajnet e mëparshme të filtrave.

-

Ventilatori i ri hidraulik me efikasitet të lartë ka një funksion automatik të kundërt që eliminon mbeturinat në bërthamë dhe nuk kërkon ndërhyrjen e operatorit.

-

Porti i mostrimit S · O · S thjeshtëson mirëmbajtjen dhe lejon marrjen e shpejtë dhe të lehtë të mostrave të vajit për analizë.

6. Siguri më e lartë:

-

Kamera e pasme është opsionale. Duke u përmirësuar në pamje 360°, do të jeni në gjendje të shihni lehtë objektet dhe njerëzit rreth ekskavatorit në një pamje të vetme.

-

Përbërësit e iluminimit me cilësi të lartë 360° dhe dritat 1800 lumen në askes, kabine, krahë, anë dhe prapa ofrojnë një pamje të plotë të makinës.

-

Mirëmbajtja e hapave të gjerë dhe perforimeve të rrëshqitshme në platformë ndihmon në parandalimin e rrëshqitjeve.

-

Treguesi i drejtimit të timonit i ndihmon operatorin të kuptojë në cilin drejtim duhet aktivizuar levja e timonit.

-

Falë shtyllave më të vogla të kokpitit, dritareve të gjera dhe dizajnit të rrafshët të kutisë së motorrit, operatorët kanë një pamje të shkëlqyeshme si në anën e brendshme të gropës, në çdo drejtim kthimi dhe pas.

-

Pas aktivizimit, çelësi i pushimit në tokë do të ndalojë plotësisht furnizimin me karburant në motor dhe do të fikë makinën.

Informacioni vjen nga web-i. Nëse po shkel, ju lutemi kontaktoni sfondin për ta fshirë !

EN

EN

ONLINE

ONLINE