SANY SY60C Classic inheritance, brand new upgrade

SANY SY60C Classic inheritance, brand new upgrade

Small excavator

SY60C

Summary

Energy saving and consumption reduction, digging soil for gold

SY75C is a 5-6 ton small excavator developed by SANY Heavy Machinery, with the characteristics of "energy saving, high efficiency, durable and reliable, low maintenance costs, intelligent driving."

SY60C national four machine around "new power," "new shape," "new technology" for a comprehensive upgrade, suitable for urban construction, garden greening, farmland transformation and other operational projects. With a high-end power and hydraulic system configuration, the power is stronger, and the application of many automotive electronics technologies makes it more comfortable and intelligent.

Main technical specifications:

Power: 36 kW / 2000rpm

Machine weight: 6000 kg

Bucket capacity: 0.25 m3

Configuration parameters

Standard: ● Option: ○ Reference: *

Bucket digging force 45 kN

Arm digging force 33 kN

Slewing speed 10.3 r / min

Walking speed 4.1 / 2.4 km / h

Slope ability 70 per cent (35 per cent)

Ground specific voltage 31 kPa

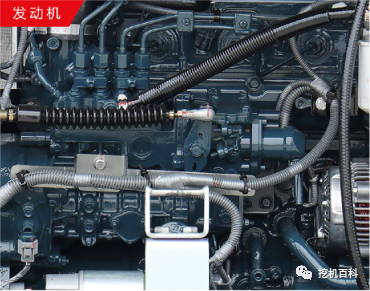

Powertrain:

Engine Kubota V2607

Frontal fixed power 36 kW / 2000 rpm

Displacement 2.615L

Emissions Standards Country IV

Hydraulic system:

Technical route load-sensitive system

The arms and arms are:

● 3000 mm boom

● 1550mm rod

●0.25 m³ 铲斗

○ 1700 mm rod

The chassis system and structure:

● 319kg weight

● 400mm track

42 tracks (one side)

● 5 axles on each side

● 1 chain wheel on each side

Oil and water injection:

Fuel Tank 125 L

Hydraulic oil tank 80 L

Engine oil 9.6L

Antifreeze 6.5 L

Final drive 2 × 0.9L

Form factor:

A. Total transport length 5915 mm

B. Total width 2025 mm

C. Total transport height 2560 mm

D. Upper width 1860 mm

E. Bulldozer height 340 mm

F. Standard track width 400 mm

G.轨距 1600 mm

H. Minimum ground clearance 315 mm

I. Rear radius of gyration 1635 mm

J. Wheelbase: 2190 mm

K. Track length 2710 mm

Operational scope:

A. Maximum excavation height 5610 mm

B. Maximum unloading height 3910 mm

C. Maximum excavation depth 3830 mm

D. Maximum vertical excavation depth 3055 mm

E. Maximum excavation radius 6070 mm

F. Minimum radius of gyration 2540 mm

G. Maximum height at minimum radius of gyration 4440 mm

H. Bulldozer lift Maximum ground clearance 401 mm

I. The maximum depth of the bulldozer is 370 mm

New upgrade - superior performance

1. Powertrain:

-

Sany custom imported engine, the fixed power of 36kW, the use of turbocharging technology, greater power and output torque, so that the machine more powerful.

-

Precision fuel injection technology guarantees excellent power and economy.

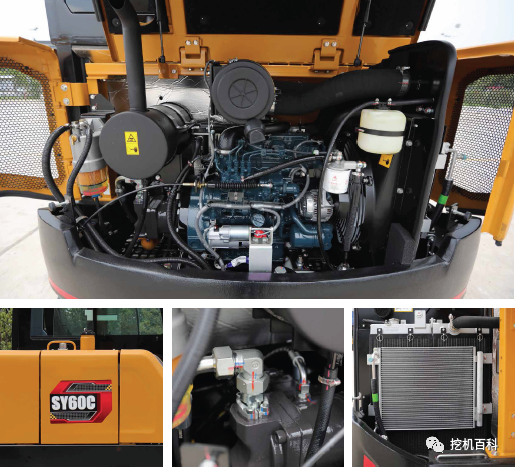

2. Hydraulic system:

-

Sany customises main pumps and main valves, and internationally renowned brands of hydraulic components to ensure high reliability of hydraulic systems.

-

The constant power algorithm has been independently developed, enabling the engine / pump / valve to be efficiently matched, and the comprehensive energy efficiency of the entire operation has been significantly improved.

-

High torque walking motor, strong power, effectively increases walking traction.

3. Load-sensitive traffic allocation system:

-

With a load-sensitive system, the operation efficiency is higher, the handling performance is better, the flooring performance is superior, and the microoperation performance is excellent.

Optimization of structural components - durability

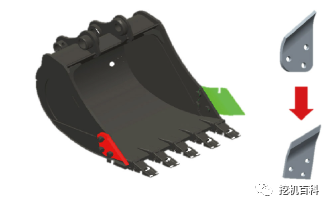

1. The shovel upgrade:

-

Strengthened rock throws, with wear-resistant steel plate at the bottom, making the shovel more powerful;

-

Optimize the secondary arc shape of the design, reduce the excavation resistance and wear of sand on the floor during excavation, and save energy and last longer;

-

Develop multi-job adaptation shovels according to market needs.

2. Arm and pole upgrades

-

The thickness of the arms strengthening plate is increased, the strength is higher, and the forging-type back support avoids the centralization of local welding stress, and the working unit life is greatly improved.

3. New lighting on the right side

-

New lighting is added to the right side of the platform to provide a better view at night and ensure the safety of the operation.

Upgrade the driver's room - a new experience

1. Exterior upgrade:

-

Trinity, in collaboration with a well-known automotive design company, has a newly upgraded exterior and a flexible and sleek feel.

-

Driving room front window beam down 117 mm, deep excavation better vision, driving room space increases, better comfort.

2. Air conditioning upgrades:

-

Automotive-grade vents are used to optimize the position of air conditioning vents and are more ergonomic, and are controlled from head to toe at a constant temperature.

3. Control system upgrade:

-

Equipped with 7 inch smart touch screen, integrated Bluetooth, USB, telephone, cassette and other functions, can freely switch multimedia audio equipment.

-

Equipped with air conditioning self-test alarm system, touch screen brightness automatic adjustment.

-

Vehicle condition information can be viewed at any time, the air conditioning temperature and wind speed can be adjusted by screen control, making it more technologically intelligent.

-

One key machine and throttle knob two is made one, scientific and technological intelligence.

4. Interior upgrades:

-

The interior is designed in a new way, with the water cup positioned in front of the right lever to reduce wind tunnel space on the right side. The multi-function panel, one button to start the machine and the throttle knob two is made one, the standard equipment water cup, 12V power supply port, USB interface and so on, more humanized.

5. Seat upgrade:

-

High-density thick cushions are used to keep the sitting shapeless for long periods of time, and a thick reclining waist support is designed to increase waist support.

-

The angle of swing of the back of the chair is greatly increased for operator movement and repose.

6. Comprehensive resonance design

-

The powertrain suspension is decoupled, and the cab module analysis is optimized to reduce vibration transmission.

Functional setup

Standard: ● Option: ○

Engine:

-

G, S, B mode control

-

12V start motor

-

60A AC Motor

-

Air Prefilter

-

Dry double filter air filter

-

Cylindrical lubrication oil filter

-

Bulk fuel filter

-

Heat heater with protective net

-

Heater sub-water tank

-

Fan curtain

-

Isolated engines

-

Automatic idling system

Driver's Room:

-

Soundproofed steel cab room

-

Strengthened light glass windows

-

4 silicone oil rubber vibration relief supports

-

Open front enclosure window, right window and left window

-

Back window emergency safe exit

-

A silent rain wiper with a cleaning machine

-

Adjustable reclining seat withdjustable armrests

-

Screen-controlled integrated radio

-

Feet boards, floor mats

-

speaker

-

Seat belt, fire extinguisher, escape hammer

-

Water cup seat, reading lamp

-

12V power port, USB interface

-

Lead control cutting rod

-

Screened air conditioning, air conditioning

The lower walking body:

-

Walking motor pads

-

Slip-on hydraulic tightening mechanism

-

Piston-connected drive wheels

-

Support wheels and chain wheels

-

Strengthening the chain link

-

400mm tread track

-

Bottom panels

Alarm system:

-

The oil pressure is too low

-

Fuel levels are too low

-

The coolant temperature is too high

-

Filter blockage

-

An engine car

-

Voltage below level

-

The voltage is too high.

Supervisory control system instrument:

-

7-inch touch display screen

-

Fault diagnosis and alarm system

-

Hour gauge, fuel level gage

-

Engine coolant temperature

-

Car phones and multimedia

Others:

-

Double electric bottle

-

Lockable front and rear hood

-

Lockable fuel filling cover

-

Left and right armcases

-

Walking direction markers on the walking rack

-

Working lights

Hydraulic system:

-

Control valve with primary overflow valve

-

A backup oil outlet for the control valve

-

Oil absorption filter

-

Reverse oil filter

-

Leading Filter

Front-end working devices:

-

French sales

-

Welding joints

-

All shovels are soldered with dust sealing rings

-

All-welded box arms

-

Completely wrought box handle

The upper pivot platform:

-

Fuel Level Sensor

-

Hydraulic Oil Level Meter

-

toolbox

-

Reverse parking brake

-

Counterweight

-

Butter bucket rack

Easy maintenance

-

The wide area covering is opened by means of opening, and after opening it can stand on the ground for daily maintenance and maintenance, and the repair is convenient and close to.

-

Adjust the height of the lifting hole to avoid the hydraulic pipe, prevent the lifting line from pressuring the hydraulic piping, and make lifting more convenient.

-

The top of the hydraulic oil tank is exposed, and the hydraulic fuel tank breath valve and refueling mouth are external to facilitate later maintenance.

-

The gas admittance system is optimized, and the position of the air filter is arranged in the engine compartment, which makes the later maintenance more convenient.

-

The manifold fuel tank pipeline is improved, and the inlet and outlet pipes are placed under the tank to facilitate high-ceiling operations.

-

The removable radiator dust net is very convenient for maintenance.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE