SANY SY135C Classic inheritance, brand new upgrade

SANY SY135C Classic inheritance, brand new upgrade

Small excavator

SY135C

Summary

Craftsman made a sales star

SY135C is a 13T class small excavator star product of Sany Heavy Machinery . In the same tonnage model , it has maintained a high market share for many years and has been sold to more than 100 countries in the world .

The all-new SY135C Tier 4 engine revolves around“New power, new technology, A new look”The new upgrade, the performance is more excellent than the third-generation machine, suitable for urban construction, road repair, earthwork, stone work, mining and other engineering operations, can meet the needs of different operations, to bring greater investment returns to customers.

Main technical specifications:

Power: 86 kW / 2200rpm

Machine weight: 13500 kg

Bucket capacity: 0.6 m3

Configuration parameters

Standard: ● Option: ○ Reference: *

Bucket digging force 103 kN

Arm digging force 67 kN

Rotary speed 12 r / min

Walking speed 5.5 / 3.5 km / h

Slope ability 70 per cent (35 per cent)

Ground specific voltage 41.7kPa

Powertrain:

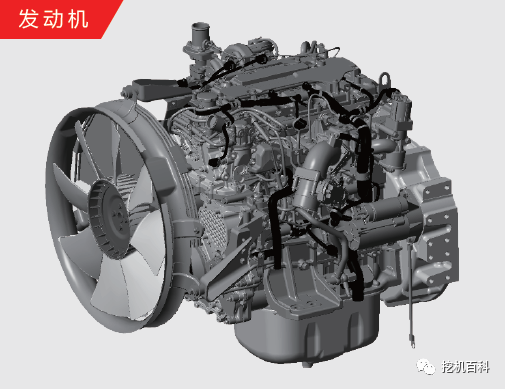

Engine Isuzu 4JJ1

Frontal power 86 kW / 2200 rpm

Displacement 2.999L

Emissions Standards Country IV

Technical route DPD + EGR

Hydraulic system:

Technical route Electric control positive flow system

The arms and arms are:

● 4600 mm boom

2500mm rod

●0.6 m³ 铲斗

The chassis system and structure:

● 2500 kg weight

500mm standard track

44 tracks (one side)

• 7 axles on each side

● 1 chain wheel on each side

Oil and water injection:

Fuel Tank 280 L

Hydraulic oil tank 200 L

Engine oil 15 L

Antifreeze 30 L

Final Drive 2 × 2.6L

Gear oil 3 L for rotary reducer

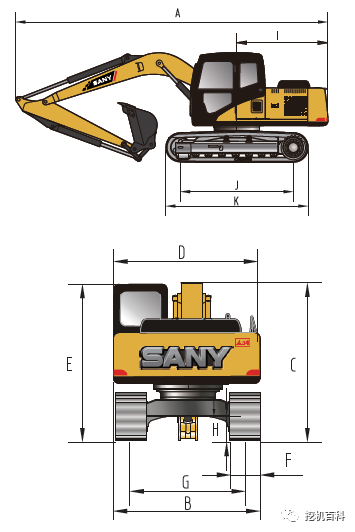

Form factor:

A. Total transport length 7890 mm

B. Total width 2490 mm

C. Total transport height 2890 mm

D. Upper width 2490 mm

E. Total height to the top of the driving room 2900 mm

F. Standard track width 500 mm

G.轨距 1990 mm

H. Minimum ground clearance 450 mm

I. Rear radius of gyration 2210 mm

J. Wheelbase: 2930 mm

K. Track length 3665 mm

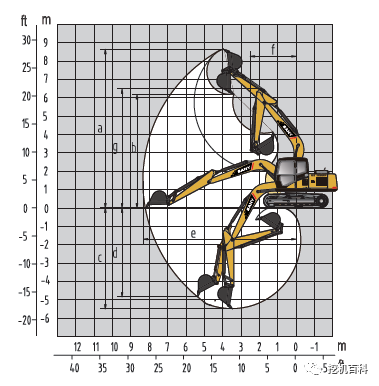

Operational scope:

A. Maximum excavation height 8800 mm

B. Maximum unloading height 6600 mm

C. Maximum excavation depth 5500 mm

D. Maximum vertical excavation depth 5085 mm

E. Maximum excavation radius 8350 mm

F. Minimum radius of gyration 2500 mm

G. Maximum height at minimum radius of gyration 6500 mm

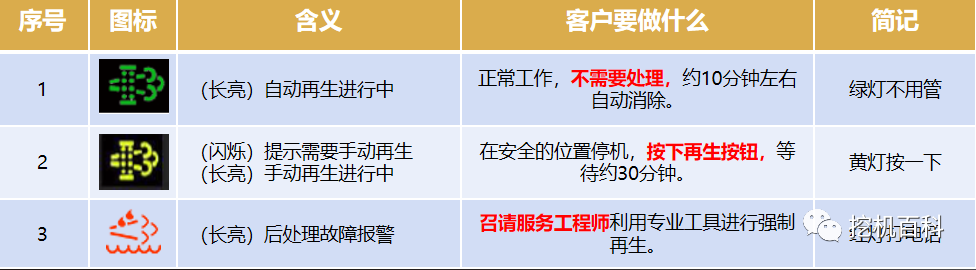

New upgrade - fuel efficient

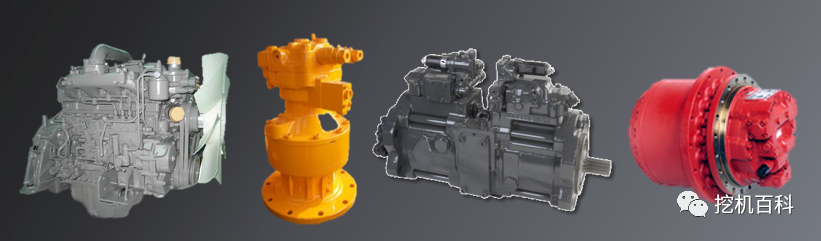

1. Powertrain:

-

Equipped with Isuzu 4JJ1 engine, the frontal power 86kW, the engine power, torque margin is larger, to ensure sufficient power, the power below 4000m plateau does not reduce.

-

A dedicated reprocessing control strategy was adopted to achieve cleaner emissions and meet national emission regulations for national emissions.

-

Combined with high-pressure co-rail electric injection technology, the fuel injection is precisely controlled in milliseconds, so that the fuel is fully burned and the fuel consumed is greater.

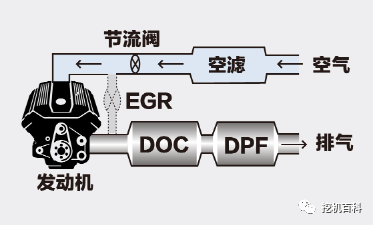

2. DPD + EGR technical route:

-

Part of the exhaust gas is recirculated into the gas admittance system, where it is mixed with fresh air and burned to suppress NOX production.

-

EGR is upgraded from tubular to laminated, cooling faster.

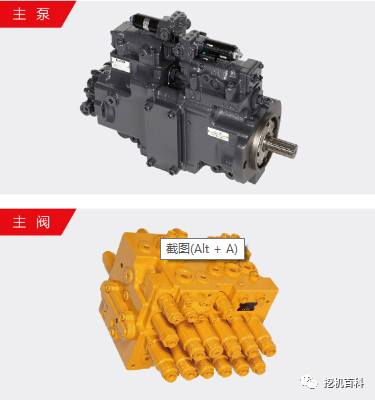

3. Hydraulic system:

-

The positive flow hydraulic system enables precise power matching and improves comprehensive energy efficiency by 5% to 8%. A simple oilway design removes logic valves to effectively avoid fixed drain losses.

-

We use well-known brands of large discharge main pump, high-performance main valve, and large-throughput main valve core, which has greater circulation capacity and less pressure loss, and comprehensively improves the overall control and fuel economy.

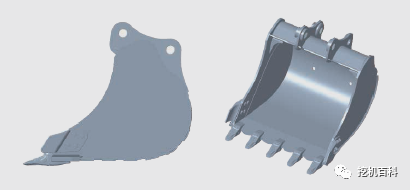

Optimization of structural components - durability

1. Low resistance wear resistant shovels:

-

The bucket shape is optimized by two arcs to reduce the digging force and work loss effectively.

-

The front blade plate is a characteristic flange structure of Sany, which avoids excessive wear and greatly improves the service life.

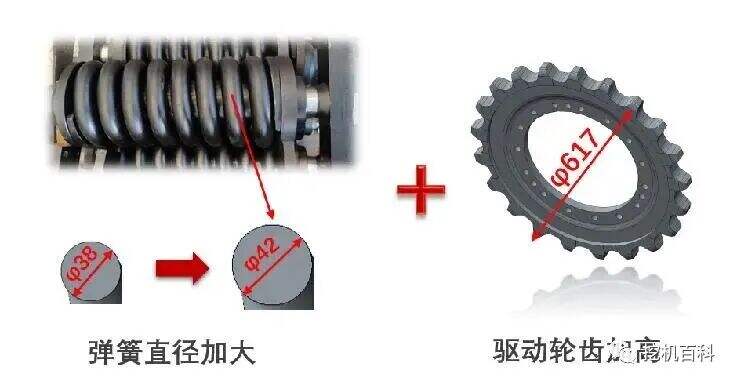

2. Get out of the car and upgrade

-

The drive wheel with higher tooth is adopted, the tooth height is increased by 16.7%, and the sludge discharge is more favorable。A strengthened tension device is used to comprehensively improve the problem of jumping teeth.

-

The new track guard board is upgraded, and the bottom contour curve is optimized according to the actual walking conditions, effectively resolving the issue of track guard and track board walking interference wear.

3. New wear resistance technology

-

Adopt new open type O type dust-proof ring, adopt cord structure, slow down wear speed.

-

The cellular high-carrying wear-resistant shaft covers, the surface self-lubricates, and the life of the moving parts is greatly improved.

Upgrade the driver's room - a new experience

1. Exterior upgrade:

-

Sany cooperated with a well-known automotive design company to upgrade the appearance, the height of the panel door increased to 1000mm, the appearance volume of the panel increased to 2470 × 2480 × 1200mm, and the space increased by 10%.The weight line is simple and stable.

2. Air conditioning upgrades:

-

The air-conditioning cooling performance is improved, the indoor temperature is reduced from 35 ° C to 25 ° C in only 15 minutes, half the time required of the competitors, and the final equilibrium temperature is lower.The vent position is ergonomic and is controlled from head to toe at a constant temperature.

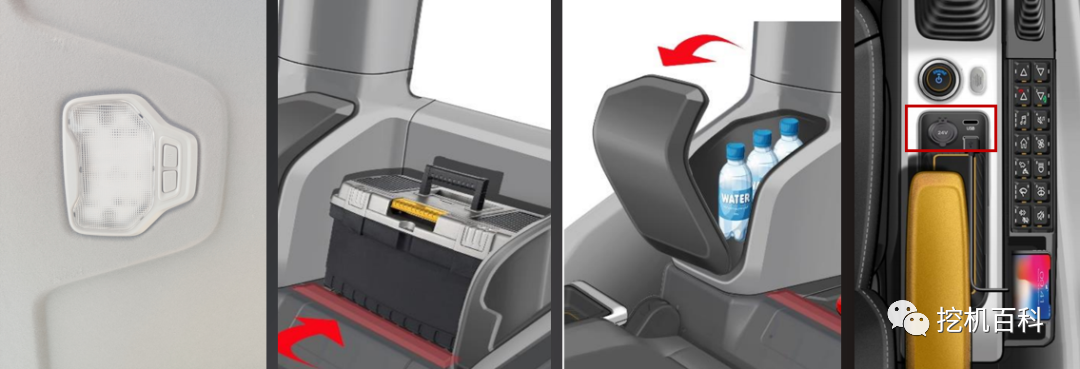

3. A new driving environment:

-

Equipped with 10-inch display screen, rear camera, a button to start the machine;

-

Standard water cup seat, mobile phone platform, sunroof sunshade, 24V access port, integrated Bluetooth call, USB interface, audio and video entertainment and other functions;

-

Optimize the steering panel and walking steering wheel for greater and more comfortable operating space

4. Sealing enhancement:

-

Using new structures and technologies, the cabin sealing performance has increased by more than 30%, effectively solving the annoyance of passengers. In cooperation with renowned universities, vibration reduction and noise reduction technology was used to reduce noise by 1 decibel.

5. Seat upgrade:

-

Seat comfort improves, with high density thick cushions that do not deform over time, and thick waist support on both sides of the back is designed to increase waist support, reduce spinal burden, and make sitting easier. Air suspension seats are configured, airbags replace the original mechanical springs to reduce shock, airbags stiffness can be adjusted with air pressure, and comfort is very good.

Functional setup

Standard: ● Option: ○

Engine:

-

H, S, L, B mode control

-

24V / 5.0kW Starter Motor

-

50A AC motor

-

Air Prefilter

-

Dry double filter air filter

-

Cylindrical lubrication oil filter

-

Bulk fuel filter

-

Oil cooler

-

Heat heater with protective net

-

Heater sub-water tank

-

Fan curtain

-

Isolated engines

-

Automatic idling system

-

Acceleration System

Driver's Room:

-

Soundproofed steel cab room

-

Strengthened light glass windows

-

6 silicone oil rubber vibration relief supports

-

Openable top, front enclosure window and left window

-

Back window emergency safe exit

-

Rain wiper with a cleaning machine

-

Mechanical shock relief seats

-

Screen controlled radio

-

Feet boards, floor mats

-

Speakers, rear view mirrors

-

Seat belts, fire extinguishers

-

Drinking cup seats, reading light

-

Escape hammer

-

Storage boxes, utility boxes

-

Lead control cutting rod

-

Screened air conditioning system

-

10-inch high-definition touch display screen

-

Launch with one click

-

Rear Camera

-

skylight

-

Lower cabin safety net

○ Protect the driver's room with a net

The lower walking body:

-

Walking motor pads

-

H-type track guide mechanism

-

Slip-on hydraulic tightening mechanism

-

Piston-connected drive wheels

-

Chain lifters and heavy lifting wheels

-

Strengthened chain rails with shaft seal

-

500mm / 1 '8 "Triple Rib Track

-

Strengthened side pedals

-

Bottom panels

○ 600 / 700mm wide track

Hydraulic system:

-

Select Button for Work Mode

-

Control valve with primary overflow valve

-

A backup oil outlet for the control valve

-

Oil absorption filter

-

Reverse oil filter

-

Leading Filter

-

Broken pipeline

Front-end working devices:

-

French sales

-

Welding joints

-

Central lubrication system

-

4.6m reinforced fully welded box boom

-

2.5m Reinforced Fully Welded Box Bucket Rod

-

Crash shields

Alarm lights:

-

The oil pressure is inadequate

-

The engine coolant overheated

-

Insufficient amount of fuel.

-

Air filter blockage

-

Fault alarm system

The upper pivot platform:

-

Sensor

-

Hydraulic Oil Level Meter

-

toolbox

-

The revolving motor

-

Rearview mirror (left and right)

Supervisory control system instrument:

-

Hour gauge, fuel level gage

-

Engine coolant temperature

-

Oil pressure gauge

Air conditioning system:

-

Air conditioner

-

Screened air conditioning system

-

Fresh air ventilation system (fresh air function)

Others:

-

Standard electric bottle

-

Lockable ceiling cover

-

Lockable fuel filling cover

-

Walking direction markers on the walking rack

-

The entire vehicle power switch

-

Fuel Fill Pump Pickup Appliance 24 V

-

Fuel injection pump

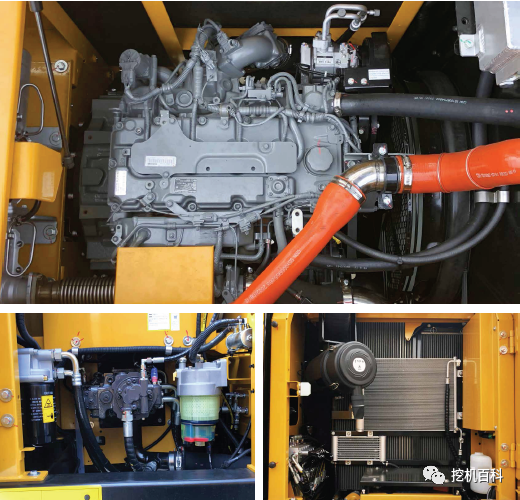

Easy maintenance

-

The wide area covering is opened by means of opening, and after opening it can stand on the ground for daily maintenance and maintenance, and the repair is convenient and close to.

-

Air filters, fuel coarse filters, exhaust filters, oil filters, and lead filters are within easy reach, and maintenance is very convenient.

-

With the inclined track rack, dirt is easier to fall, does not pile up on the track rack in large quantities, and cleaning is easily done.

-

The butter filling mouth on the work unit is centrally arranged to supply the grease long distance to difficult-to-reach areas, making lubrication and maintenance more convenient.

-

There is a special safety net on the outside of the radiator, and simply remove the safety net to clean the dirty side. Excellent heat dissipation ensures that the engine does not run at high temperatures for long periods of time.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE