CAT 336GC Classic inheritance, brand new upgrade

CAT 336GC Classic inheritance, brand new upgrade

Large excavator

336GC

-

Up to 5% more fuel efficient

-

New driveway, more comfortable and safer

-

Up to 15 percent Lower maintenance costs

Configuration parameters

Standard: ● Option: x To be perfected: / Reference value: *

1. Performance parameters:

|

force |

Maximum traction force |

/ |

kN·m |

|

Bucket Digging Force - ISO |

197 |

kN |

|

|

Standard Arm Digging Force - ISO |

148 |

kN |

|

|

Rotation torque |

137 |

kN·m |

|

|

speed |

Reverse speed |

8.74 |

r/min |

|

行走高速/低速 |

/ |

km/h |

|

|

noise |

Operator voice pressure (ISO 6396:2008) |

/ |

dB(A) |

|

Average external sound pressure (ISO 6395:2008) |

/ |

dB(A) |

|

|

Other |

Ability to climb slopes |

35 |

degree |

|

Ground is higher than pressure |

/ |

kPa |

2. Powertrain:

|

Engine Model |

Cat C7.1 |

|

|

rated power |

195 |

kW |

|

discharge volume |

7.1 |

L |

|

Emissions Standards |

Country 4 |

|

|

Emissions routes |

/ |

|

|

Engine Speed - Running |

2000 |

rpm |

|

Engine Speed - Operation |

1900 |

rpm |

3. Hydraulic system - fully electrically controlled:

|

Stress: |

||

|

Working pressure - equipment |

35000 |

kPa |

|

Working Stress - Driving |

35000 |

kPa |

|

Stress at work - turnaround |

28000 |

kPa |

|

Traffic: |

||

|

Main system - equipment |

559 |

L/min |

|

Reverse System |

/ |

L/min |

|

Fuel tank: |

||

|

Armed cylinder: cylinder length - stroke |

/ |

mm |

|

Bulk cylinder: cylinder length - stroke |

/ |

mm |

|

Shovel oil tank: cylinder length - stroke |

/ |

mm |

4. Working appliance:

|

Move your arms |

6500 |

mm |

|

Standard clubs |

3200 |

mm |

|

The shovel fighter looks |

1.88 |

m³ |

5. The chassis system:

|

Trackboard width |

600 |

mm |

|

Number of trackpads - one side |

/ |

section |

|

Number of support wheels - one side |

7 |

individual |

|

Torch wheel - one side |

2 |

individual |

|

Weight of weight |

6800 |

kg |

6. Amount of oil and water added:

|

Fuel tank |

600 |

L |

|

Hydraulic system |

373 |

L |

|

Hydraulic fuel tank |

161 |

L |

|

Engine oil |

20 |

L |

|

Cooling system |

19 |

L |

|

Reverse drive (each) |

18 |

L |

|

Ultimate drivers (each) |

8 |

L |

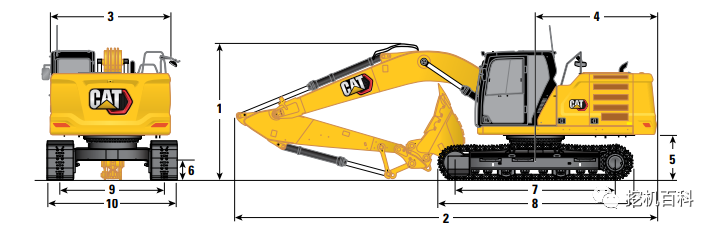

7. Form factor:

|

1. |

Height of the machine |

||

|

Height of the top of the cab |

3170 |

mm |

|

|

Total height (at the time of transport) |

/ |

mm |

|

|

2. |

Machine length |

11170 |

mm |

|

3. |

Height of the upper rack |

/ |

mm |

|

4. |

Tail pivot radius |

3530 |

mm |

|

5. |

Weight Gap |

1250 |

mm |

|

6. |

Gaps between ground level |

510 |

mm |

|

7. |

Distance between centres of heavy rolling stock |

||

|

Long chassis |

4040 |

mm |

|

|

Standard chassis |

3610 |

mm |

|

|

8. |

Track length |

||

|

Long chassis |

5030 |

mm |

|

|

Standard chassis |

4590 |

mm |

|

|

9. |

Track length |

2590 |

mm |

|

10. |

The chassis width |

3190 |

mm |

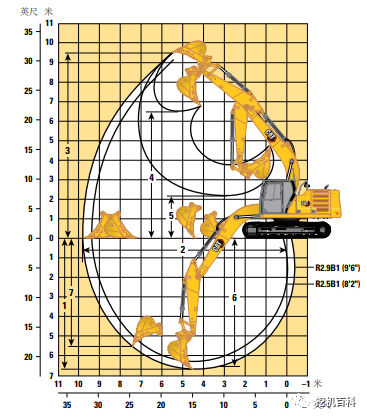

8. Operational scope:

|

1. |

Maximum excavation depth |

7520 |

mm |

|

2. |

Maximum stretch distance of the ground |

11050 |

mm |

|

3. |

Maximum mining height |

10300 |

mm |

|

4. |

Maximum loading height |

7080 |

mm |

|

5. |

Minimum load height |

2580 |

mm |

|

6. |

2440mm Flat Maximum Dig Depth |

7360 |

mm |

|

7. |

Maximum vertical excavation depth |

5660 |

mm |

Functional configuration

Standard: ● Option: ○

1. Troops, clubs, and clubs:

|

Standard |

Matching |

|

|

6.5 m(21'4" ) Stretch your arms |

● |

|

|

6.18 m(20'3" ) Take a big fight to move your arms |

○ |

|

|

6.5 m(21'4" ) Stretch your arms |

○ |

|

|

2.8 m(9'2" ) Fighting Stick |

○ |

|

|

3.2 m(10'6" ) Fighting Stick |

○ |

|

|

3.9m(12'10" ) Fighting Stick |

○ |

2. Electrical systems:

|

Standard |

Matching |

|

|

1000 CCA maintenance-free battery (× 2) |

● |

|

|

Centralized Electrical Shutdown Switch |

● |

|

|

LED chassis lights, left and right extension arm lights, driving room lights |

● |

3. Engine:

|

Standard |

Matching |

|

|

Two optional modes: strong intelligence |

● |

|

|

Automatic engine speed control |

● |

|

|

Working altitude up to 3300 m |

● |

|

|

52 ° C (125 ° F) high temperature ambient cooling capacity |

● |

|

|

18 ° C (0 ° F) cold start capability |

● |

|

|

Dual-filter air filter with integrated prefilter |

● |

|

|

Remotely disable |

● |

|

|

Biodiesel with the highest label B20 can be used |

● |

|

|

-32 ° C (-25 ° F) cold start capability |

○ |

|

|

Cold starting cylinder heater |

○ |

|

|

Hydraulically able to turn the fan |

○ |

4. Hydraulic system:

|

Standard |

Matching |

|

|

The arms and pole regeneration circuit |

● |

|

|

Electronic main control valve |

● |

|

|

Automatic hydraulic oil preheating |

● |

|

|

Reverse turning dampers valve |

● |

|

|

Automatic reverse parking brake |

● |

|

|

High Performance Hydraulic Oil Recovery Filter |

● |

|

|

Working at two speeds |

● |

|

|

Be able to use bio-hydraulic oil |

● |

|

|

Longer chassis system (Indonesian only) |

● |

|

|

Standard chassis system |

● |

|

|

Precision turning |

○ |

|

|

A one-way auxiliary circuit |

○ |

|

|

Combined two-way auxiliary circuit |

○ |

|

|

Combined two-way auxiliary circuit with hydraulically powered impact hammer return filter |

○ |

|

|

Medium pressure auxiliary circuit |

○ |

|

|

Fast connector circuit |

○ |

5. The chassis system and structure:

|

Standard |

Matching |

|

|

A tractor ring on the chassis |

● |

|

|

6.8mt Counterweight |

● |

|

|

600mm(24" ) Three-clawed ground teeth track plate |

○ |

|

|

700 mm(28" ) Three-clawed ground teeth track plate |

○ |

|

|

800 mm(31" ) Three-clawed ground teeth track plate |

○ |

|

|

850mm(33" ) Three-clawed ground teeth track plate |

○ |

6. Safety and protective devices:

|

Standard |

Matching |

|

|

Caterpillar One Key Safety System |

● |

|

|

Lockable external tool / storage box |

● |

|

|

Lockable doors, fuel tanks and hydraulic tank locks |

● |

|

|

Lockable fuel emission chamber |

● |

|

|

Maintenance platform with anti-skateboarding and embedded bolts |

● |

|

|

Standard field rearview mirror suite |

● |

|

|

Right hand rails and handles (according to ISO 2867: 2011) |

● |

|

|

Ground engine stop switch |

● |

|

|

Signal / alarm horn |

● |

|

|

BACK VIEW camera |

● |

|

|

Right-View Camera |

○ |

7. Driver's Room:

|

Standard |

Matching |

|

|

ROPS structure with sound insulation |

● |

|

|

Mechanically adjusted seat |

● |

|

|

High-Resolution 203mm (8 inches) LCD touch screen monitor |

● |

8. CAT Technology:

|

Standard |

Matching |

|

|

Cat Product Link™ |

● |

9. Repair and maintenance:

|

Standard |

Matching |

|

|

Centralized lubrication oil filter and fuel filter |

● |

|

|

Planned analysis of oil sample (S · O · S) sampler |

● |

|

|

Electric fuel pump with automatic disconnect function |

○ |

Performance Overview

1. Moving more materials with less fuel:

-

In similar applications, the digging machine reduces fuel consumption by up to 5% compared to the 336D2.

-

The C7.1 engine complies with China's non-road Stage III emission standard, equivalent to the US EPA Tier 3 and EU Stage IIIA standards.

-

Available in two power modes, the excavator is suitable for a variety of types of operations. Automatically match engine and hydraulic power to your excavation conditions through smart mode, providing maximum power when needed and reducing power when not needed to help save fuel.

-

The advanced hydraulic system not only achieves the optimal balance between power and efficiency, but also gives you the control devices you need to meet your precise excavation requirements.

-

The valve prioritization allows the hydraulic pressure and flow to reach the level you set for a light to medium load cycle quickly.

-

Advansys™The shovel teeth improve penetration capacity and shorten cycle time. A simple lug wrench, rather than a hydraulically powered impact hammer or special tool, can be used to quickly change the tips for improved safety and extended uptime.

-

Add an auxiliary pressure system to do more work with a variety of different Cat tooling.

-

Product Link™Standard accessories, so you can remotely monitor machine health, location, hours and fuel consumption as needed via the VisionLink ® online interface.

2. Outstanding performance:

-

Working altitudes up to 3300 m (10830 ').

-

Can operate at high temperatures up to 52 ° C (125 ° F) and cold start up to -18 ° C (0 ° F).

-

The automatic hydraulic oil preheating function allows you to work faster in cold weather and helps extend the service life of your components.

-

Double fuel filtering prevents the engine from being affected by dirty diesel fuel.

-

Sealed between the track solder and the liner by grease can reduce driving noise and prevent debris from entering, thereby extending the service life of the chassis system.

-

When the excavator is moving and working on a slope, the central track leading guard helps keep the excavator track aligned.

-

The inclined track rack prevents the accumulation of dirt and debris, and therefore helps to reduce the risk of track damage.

3. Designed for operators:

-

The comfortable driver's room is equipped with wide seats that can be flexibly adjusted to suit operators of all sizes.

-

The touchscreen control devices are located in front of the operator, making it easy for the operator to control the excavator comfortably.

-

Standard automatic thermostats ensure a comfortable temperature throughout the operation.

-

The advanced rigid base reduces vibration in the cab by up to 50 per cent compared to previous excavator models.

-

Under the rear of the seats, overhead and in the control room provide plenty of drive room space to easily store your gear.

-

Personal devices can be connected using a standard wireless USB port and Bluetooth ® technology.

4. It's easy to do:

-

Start the engine by a button; Use a Bluetooth key fob, smart phone app, or operator ID password.

-

Program each joystick button using the operator ID, including power mode and response; The machine remembers these programming and calls them every time you operate the machine.

-

With the help of a high-resolution 203 mm (8 " ) Standard touch screen monitor or knob control for quick navigation.

-

Prevent hydraulically powered impact hammer overload. The hydraulically powered impact hammer stop signal lasts for 15 seconds and then shuts off automatically after 30 seconds to prevent tool and excavator wear.

-

Don't know how a certain function works or how to maintain an excavator? The operator manual is accessible at any time with a touch of the finger on the touch screen monitor.

-

Cat Locator is a Bluetooth ® device that quickly and easily helps you find tooling and other equipment.The excavator's onboard Bluetooth reader or the Cat app on your phone will automatically locate the device.

5. Lower maintenance costs:

-

Due to the longer service intervals, maintenance costs are expected to decrease by up to 15% compared to the 336 F. (Savings calculated according to the 12,000 hours worked by the machine.) )

-

Hydraulic system oil can be inspected from the ground and water in the fuel system and fuel tank can be easily discharged.

-

The filter life and maintenance cycle of the excavator can be tracked through a monitor in the driving room.

-

Replace all fuel filters after 1,000 hours of arrival in sync. The oil and fuel filters are centrally installed on the right side of the machine for easy maintenance.

-

The dust containing capacity of the new inlet filter is twice as much as that of the previous inlet filter.

-

The new hydraulic oil filter provides better filtration performance, and the reverse drain valve keeps the oil clean when the filter is replaced at a time of up to 3,000 working hours, giving a longer service life - 50% longer than previous filter designs.

-

The proximity of the S · O · S sampling port to the ground simplifies maintenance and enables quick and easy extraction of oil samples for analysis.

6. Safety features in the driving room:

-

Protect your digging machine with operator ID. Use your PIN code on the monitor to enable button launch.

-

The standard ROPS driving room meets the requirements of ISO 12117-2: 2008.

-

The steering direction indicator helps the operator understand which direction to activate the steering lever.

-

Once activated, the ground downtime switch will completely stop the delivery of fuel to the engine and shut down the machine.

-

Thanks to the use of smaller cockpit columns and wide windows, operators have an excellent view, whether on the inner side of the ditch, in each direction of rotation or in the rear of the operator.

-

Maintenance of the jagged steps and slippery perforations on the platform help prevent slips.

-

The rearview camera is a standard accessory.

The information comes from the web. If it is infringing please contact the background to delete it!

EN

EN

ONLINE

ONLINE