7 operating methods and maintenance of Kubota excavator crushing hammer

7 operating methods and maintenance of Kubota excavator crushing hammer

7 operating methods and maintenance of Kubota excavator crushing hammer

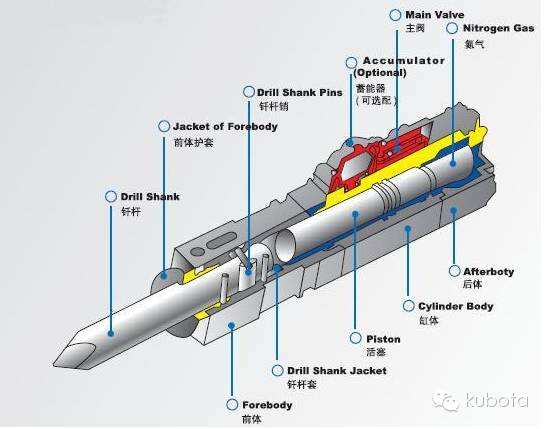

Since most broken hammers have reserved oil outlet joints with accessories when they come out of the factory, when installing the hammer, the pipe and joint must be connected to the hammer as required by the instruction manual.

1.Operation method: Proper operation can improve the operational efficiency of the crushing hammer and can extend the service life. There are a few operational considerations:

(1) When each use, the high-pressure or low-pressure oil pipe of the crushing hammer should first be inspected for looseness. At the same time, for the sake of caution, it should be always inspected for oil leaks elsewhere, so as not to cause the oil pipe to fall out due to vibration, thereby breaking down.

(2) During the operation of the crushing hammer, the shaft shall always be kept in a vertical state with the surface of the broken object. And make the shaft squeeze the broken object tightly, and stop the crushing hammer immediately after the crushing to prevent empty blowing. A sustained and untargeted impact can cause damage to the precursor of the crushing hammer and loosening of the main bolt, which in severe cases can injure the main itself.

(3) Do not use the shovel when crushing, otherwise the main bolt and the shovel are likely to crack. Do not let the crushing hammer fall rapidly or hit hard rock, which will damage the crushing tool or the main due to excessive impact.

(4) Do not carry out crushing operations in water or muddy ground. Other parts of the crushing hammer body, other than the shaft, should not be immersed in water or mud, otherwise the pistons and other similarly functioning parts on them will accumulate dirt and cause premature loss of the csmash hammer.

(5) When crushing a particularly hard object, it should start from the edge first, and do not beat continuously at the same point for more than 1 min to prevent the drill rod from burning or overheating.

(6) Do not use the guard plate of the crush hammer as a tool to push heavy objects. Since excavator loaders are mainly small machines, their own weight is light, and if they are used to push a heavy object, the light will damage the crush hammarb, the heavy will cause the main suspension arm to break, and even the main rolling accident.

(7) Do not operate when the hydraulic cylinder is fully stretched or contracted, otherwise the impact vibration will be transmitted to the hydraulic body and thus to the main.

2.Maintenance: Because the working conditions of the crusher are very harsh, correct maintenance can reduce the failure of the machine and extend the service life of the machine. In addition to timely maintenance of the mainframe, the following points should be noted:

(1) Exterior inspection. Check whether the relevant bolts are loose The joint solder shafts are excessively worn Check whether there is a normal gap between the shaft and its lining and whether there are oil leaking between them, indicating that the low pressure oil seal is damaged and should be replaced by a professional.

(2) lubricate. The lubricating point of the working device should be lubricated before operation and after each continuous operation for 2 to 3 hours.

(3) Replace the hydraulic oil. The change of hydraulic oil quality varies depending on the working environment. The simple way to judge whether the oil is good or bad is to observe the color of the oil. When the deterioration of the oil is extremely severe, the oil should be discarded and new oil should be injected after cleaning the tank and filter.

(4) The main part of the crushing hammer is a set of precision parts containing a hydraulic circulation system. Generally, factories without special equipment do not decompose themselves, and must commission maintenance.

---The above is KubotaKubota excavatorcrusher operation and maintenance plan

Please study and refer to,---read thisarticle if you are useful please like, collect and transfer;Thank you

---The use of the machine lies in maintenanceIt needs rest and energy as much as we humans do!!! It needs us to carefully take care of every part of it! --- Shanghai Hangkui Construction Machinery Co.Ltd specializes in wholesale sales of all series of Japanese Kubota machinery and equipment parts for repair, consultation, information, technical support, experience sharing, communication, after-sales service!

Professional wholesale sales of Kubota parts of Japan Kubota excavator parts Kubota engine parts Kubota construction machinery parts Kubota agricultural machinery parts Kupota generator parts Kubota pump parts Kubota electric appliance parts Kubota chassis parts Kubota Maintenance Parts Cat Excavator Parts Cat Loading Machine Parts Cat Snowplow Parts Germany BMW Road Sweeping Parts, Technical support, repair, after-sales service;

EN

EN

ONLINE

ONLINE